Method for regulating chemical components of tobacco material

A chemical composition and tobacco technology, applied in the field of tobacco technology, can solve problems such as uncontrollable chemical composition of expanded cut tobacco

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

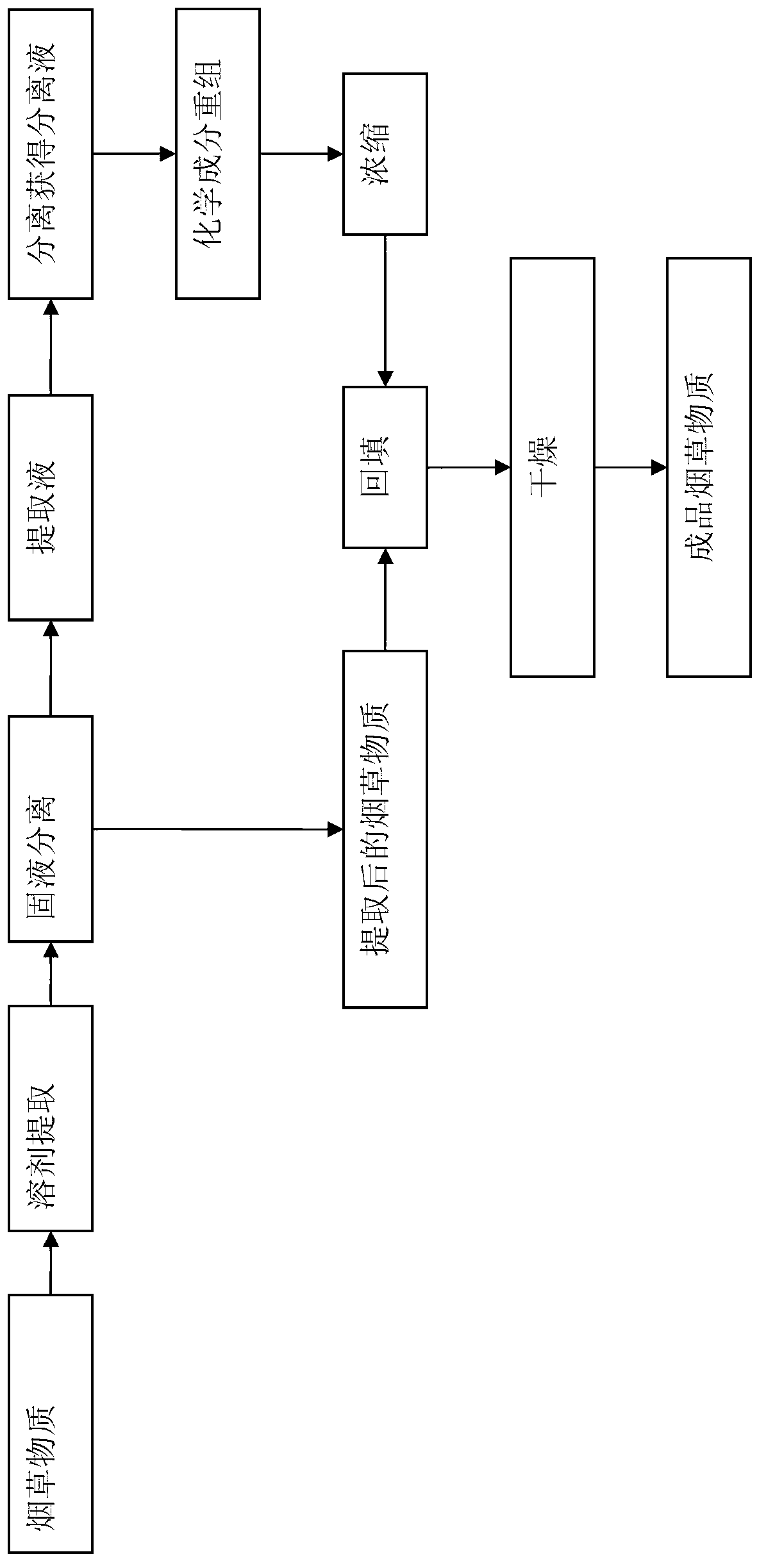

Method used

Image

Examples

Embodiment approach

[0051] According to an embodiment of the present invention, the tobacco substance includes one or a mixture of tobacco leaves, tobacco sheets, tobacco stems, shredded tobacco, and shredded stems. It may be one of them, or a mixture of several of them.

[0052] According to one embodiment of the present invention, the solvent is water or ethanol solution or glycerin or propylene glycol solution or edible wine with a concentration of 90% or less. The edible wine is used as a solvent, and the final tobacco product has a special taste of edible wine.

[0053] According to an embodiment of the present invention, the chemical substances of the tobacco product include soluble sugars, organic acids, proteins, alkaloids, and inorganic salts. In view of the complexity of the chemical substances contained in tobacco products, only the above categories are listed here. In the present invention, all or part of the soluble chemical substances in the tobacco material are extracted through ...

Embodiment 1

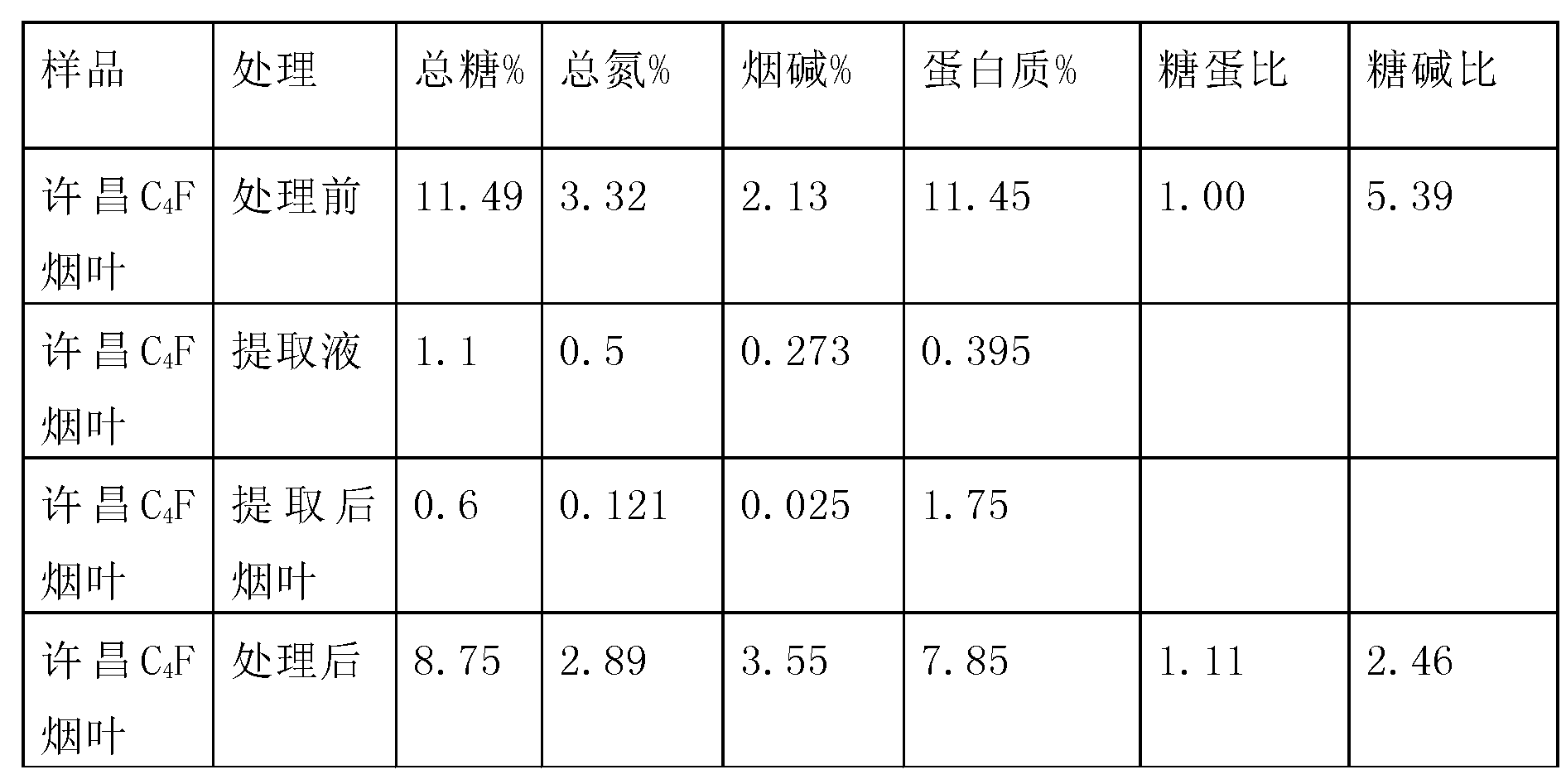

[0063] Embodiment one: flue-cured tobacco leaf low sugar-alkali ratio processing

[0064] Take Xuchang C 4 1 kg of F tobacco leaves was used as the test raw material, and water was used as the extraction solvent for processing.

[0065] 1. Extraction: Xuchang C 4 1kg of F tobacco leaves (moisture content: 12%) were extracted with 10kg of distilled water at room temperature for 1 hour and squeezed dry to obtain 7.6kg of extract and 3kg of extracted tobacco leaves.

[0066] 2. Separation: 7.6kg of extract is separated by ultrafiltration membrane (cutting molecular weight 8000 Daltons), the temperature is controlled at ≤40°C, the pressure is controlled at ≤23Mpa, and the interception of low nicotine content intercepted by the ultrafiltration membrane is separated. 3.5kg of dialysate (the detected nicotine content is 0.09%), and 5kg of dialysate with high nicotine content (the detected nicotine content is 0.44%) passed through the ultrafiltration membrane.

[0067] 3. Recombina...

Embodiment 2

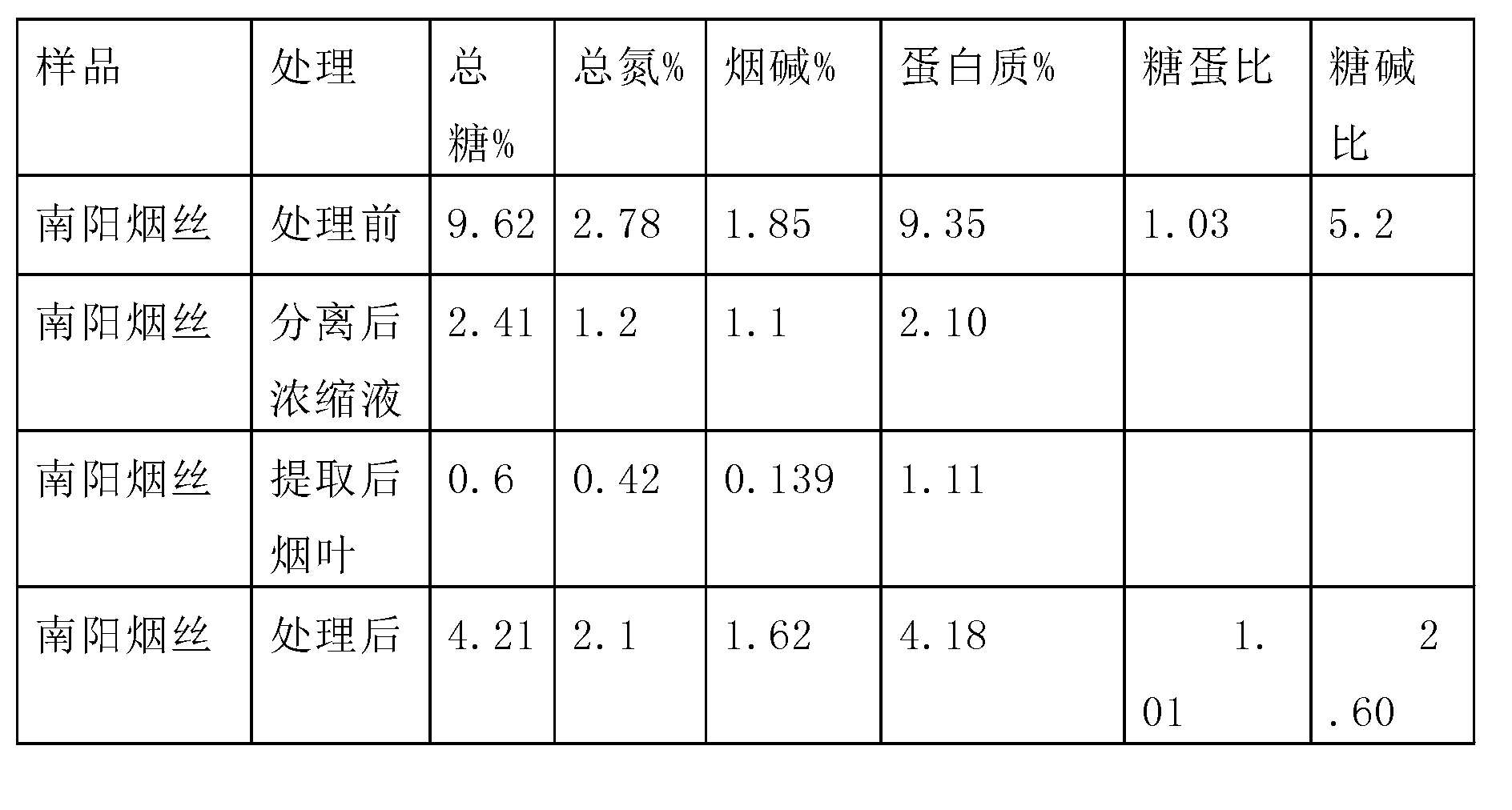

[0077] Example 2: Low-sugar treatment of flue-cured tobacco single-material shredded tobacco

[0078] Take 1kg of Nanyang shredded tobacco as the test raw material, and use water as the extraction solvent for this treatment.

[0079] 1. Extraction: 1kg of Nanyang shredded tobacco (moisture content: 12%) was extracted with 10kg of water at room temperature for 1 hour and squeezed dry to obtain 7.7kg of extract and 2.87kg of extracted tobacco leaves.

[0080] 2. Separation: 7.7kg of the extract was separated by water extraction and alcohol precipitation. Concentrate the extract to 1kg (solid content is about 43%). After cooling, stir and add 1.5kg of ethanol (analytical alcohol with a concentration of 99.5%). After standing for 2 hours, filter out the precipitate, and concentrate the filtrate to 40% again. % solid content concentrate; the filtered sediment is mainly composed of sugar, starch, pigment and protein. The protein content of the precipitate was 4.79%, and the total ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com