Preparation method and application of dye adsorbent

An adsorbent and dye technology, applied in the field of preparation of dye adsorbents, can solve the problems of toxic by-products or secondary metabolites, time-consuming biodegradation methods, cumbersome preparation process, etc., to avoid secondary pollution risks, The effect of avoiding secondary pollution problems and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Take mature cedar needles, dry them at 75°C for 48 hours, take them out, grind them and sieve them to get a powder with a particle size of about 300-800 μm, soak the obtained powder with absolute ethanol for about 1 hour to degrease, Remove organic pigment, filter and rinse the precipitate with phosphate buffer solution with a concentration of 10mM (pH=4.5) three times, take the precipitate and dry it at 75°C for 48 hours, use a mortar to slightly break the powder agglomerate until it is uniform. As an adsorbent for decolorization.

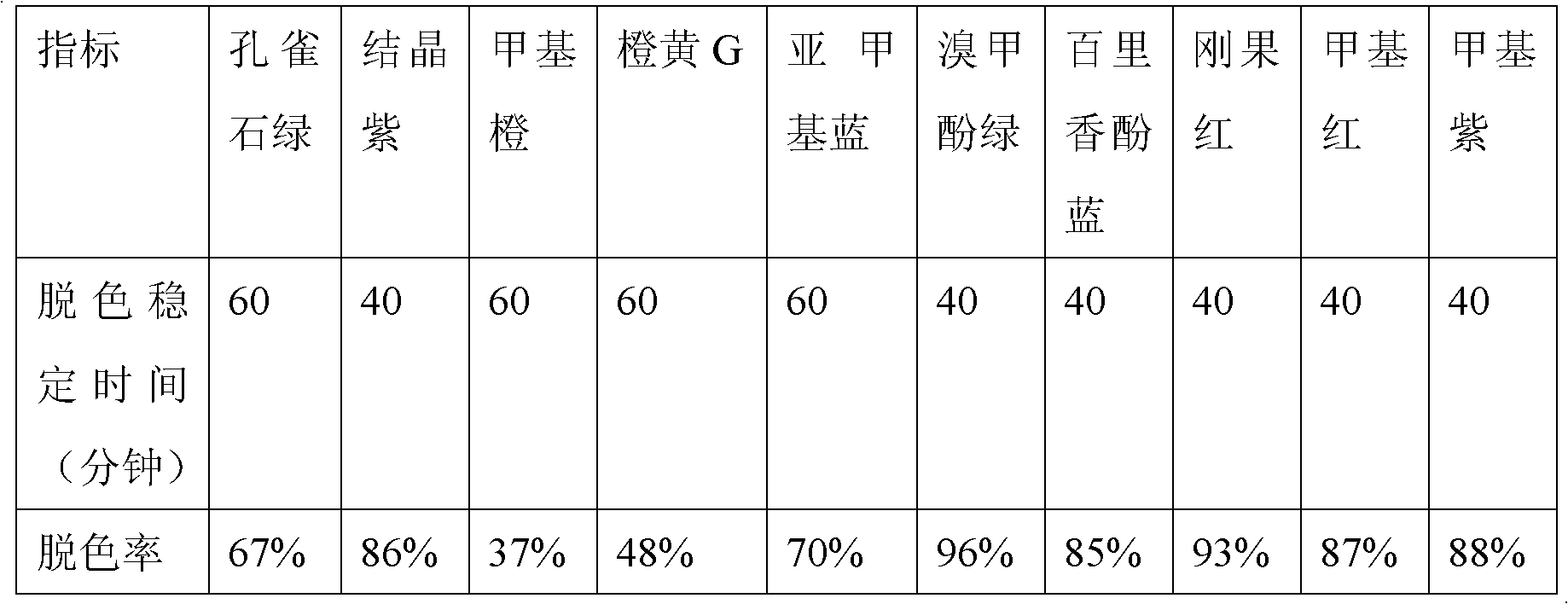

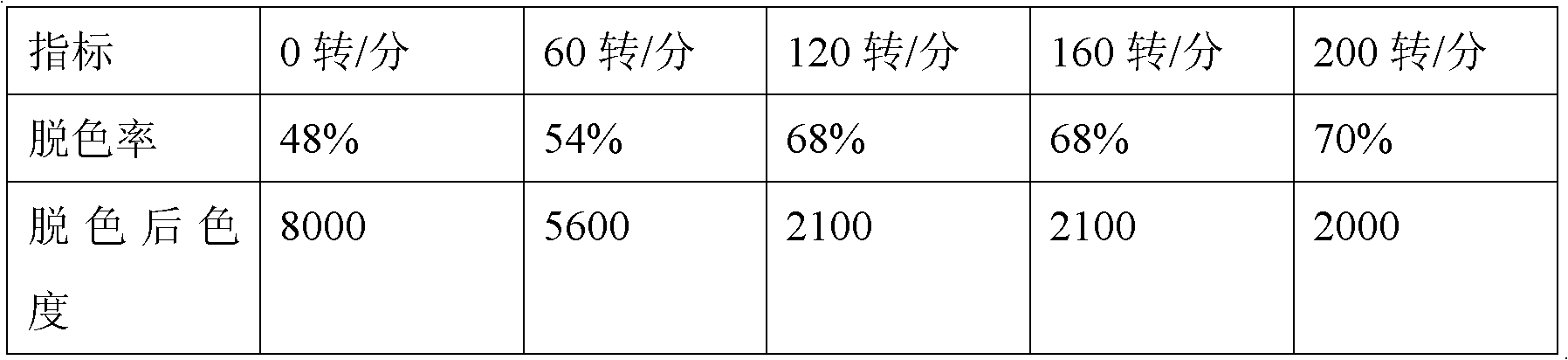

[0039] Wastewater (chromaticity is about 50000 times, pH=9) is taken from a printing and dyeing factory, precipitated and filtered as a decolorization solution, and the dye wastewater is decolorized by using the adsorbent provided by the invention. The prepared adsorbent is directly added to the waste water, so that the concentration of the adsorbent in the waste water is 1.5g / 100ml, and the decolorization is carried out at a room temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com