Flat grinding machine

A flat grinder and frame technology, which is applied to grinding machines, machine tools suitable for grinding workpiece planes, and machine tools suitable for grinding workpiece edges, etc., can solve problems such as high cost, low grinding efficiency, and complex structure, and achieve Eliminates slippage, improves grinding efficiency, and expands the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

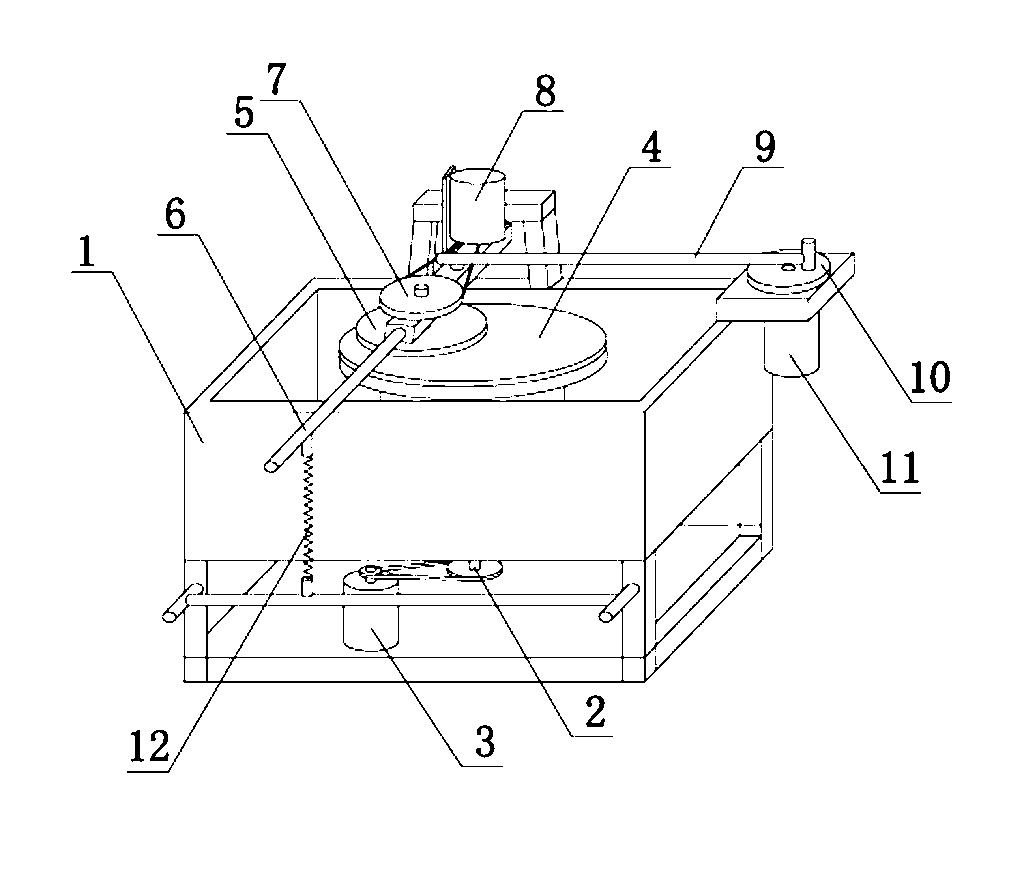

[0030] Example: such as figure 1 As shown, a flat grinding machine includes a frame 1, a main shaft 2 is arranged on the frame 1, a grinding disc 4 is connected to the upper end of the main shaft 2, a main motor 3 is connected to the lower end, the grinding disc 4 is a diamond grinding disc, and the end surface of the grinding disc 4 is crimped Fitted with a pressure plate 5, the pressure plate 5 is connected to the lower end of the rotating shaft on the guide rod 6, the upper end of the rotating shaft is provided with a driven wheel 7, and the driven wheel 7 is in phase with the driving wheel (not shown) on the motor shaft of a motor 8. Connected, a motor 8 is arranged on the guide rod 6, and the rotation direction of the rotating shaft is opposite to that of the main shaft 2.

[0031] One end of the guide rod 6 is movably hinged on the frame 1, and the other end is provided with a pressure spring 12 that tightly presses the pressure plate 5 on the grinding plate 4. One end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com