Production method for injection molding machine workpiece production line

A production line and injection molding machine technology, applied in the field of computer integrated manufacturing, can solve problems such as single structure, dependence on initial solution, and no effective solution algorithm found

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

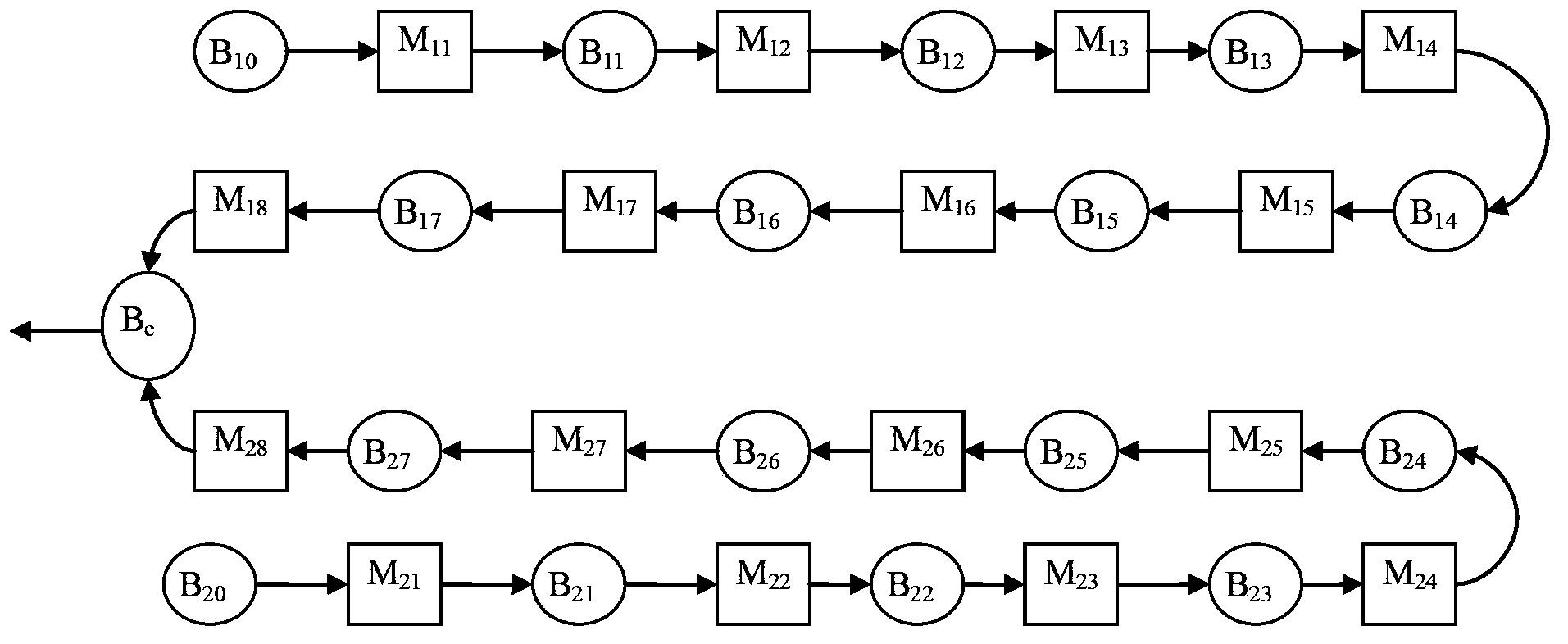

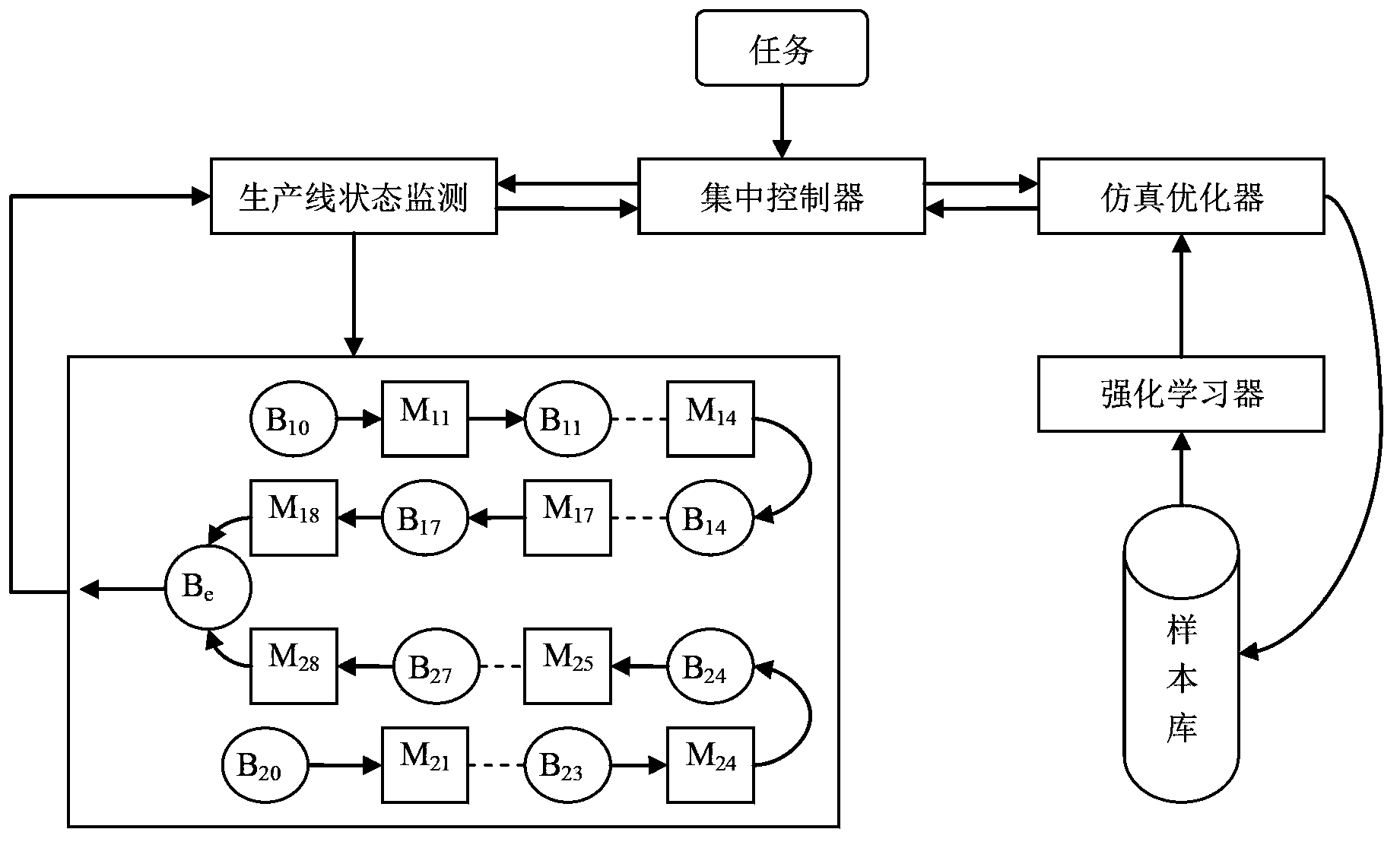

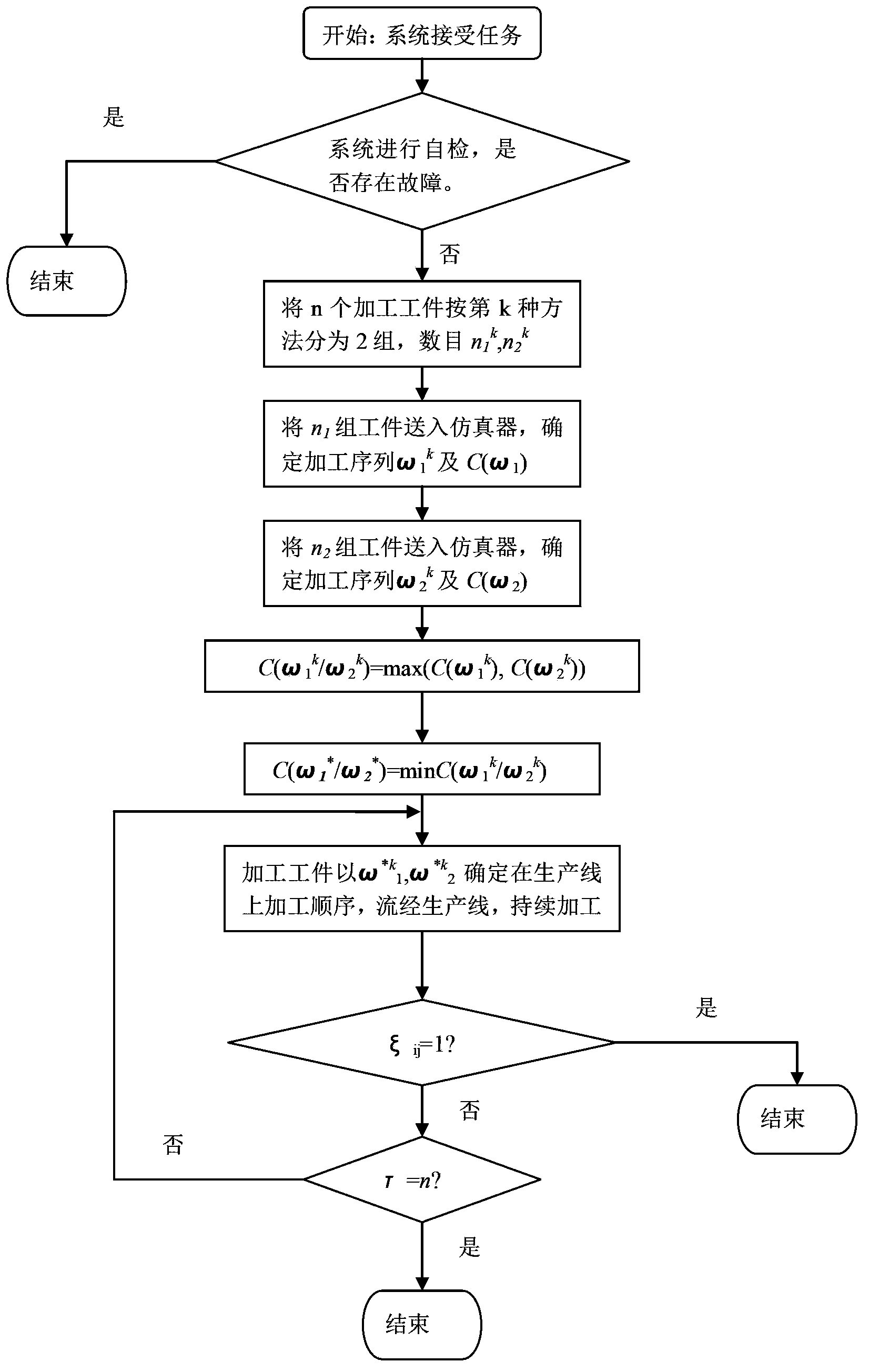

[0045] 1. Double-line structure production system for injection molding machine workpieces

[0046] The injection molding machine workpiece production system involved in the present invention is a double production line structure, such as figure 1 As shown in the figure, M ij Represents the j processing equipment on the i-th production line, B ij Indicates the device M ij The backward trend buffer. The system consists of 2 assembly lines, and each assembly line is composed of 8 sequential processing equipments, which respectively undertake the following technological tasks: surface milling, groove milling, drilling, reaming, thread processing, surface grinding, polishing, sandblasting. There is a buffer between devices. The production of injection molding machine workpieces is characterized by fine classification and many types. Even for workpieces of the same type of structure, due to different sizes, the processing time of each process is different. Each process of workp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com