Preparation method for cathode active material of lithium ion battery

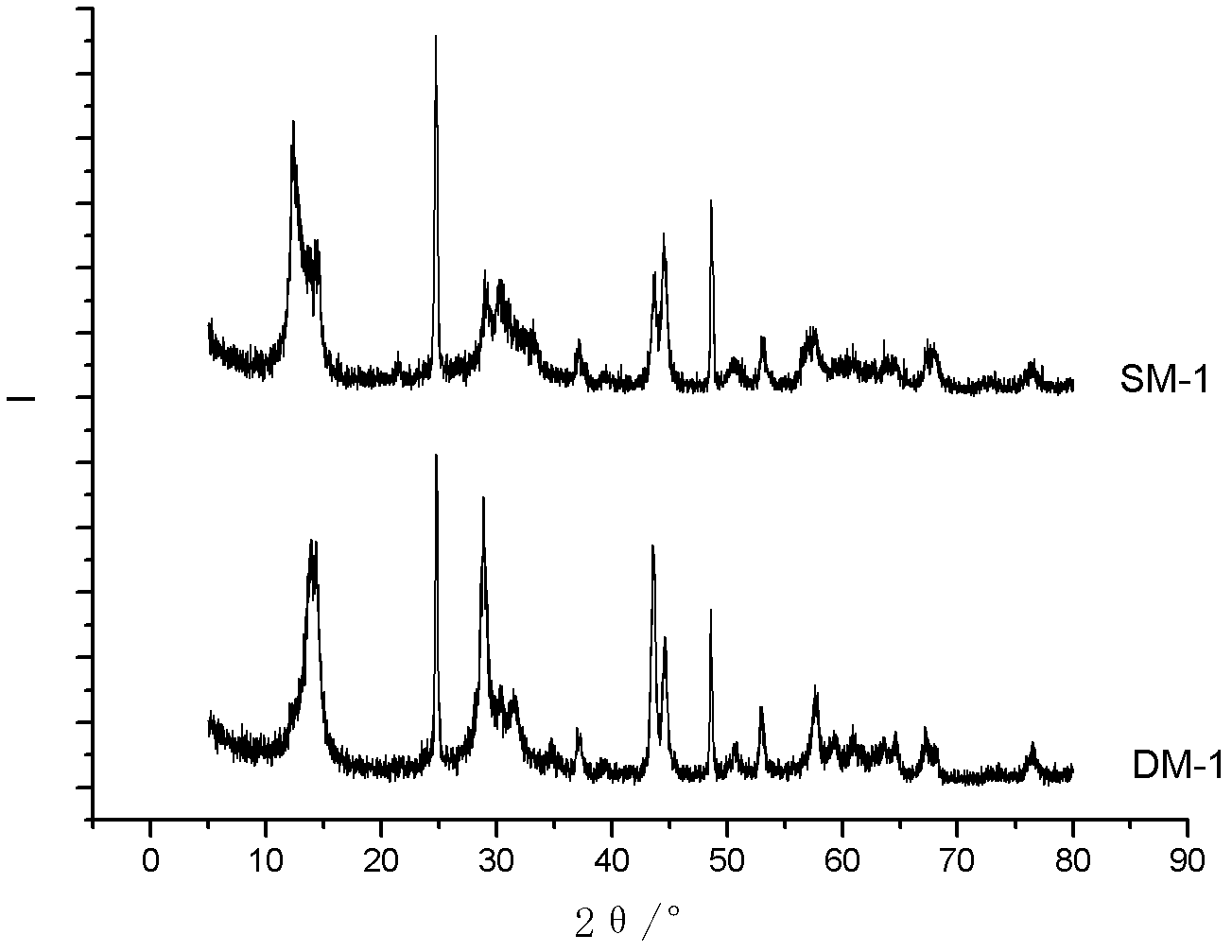

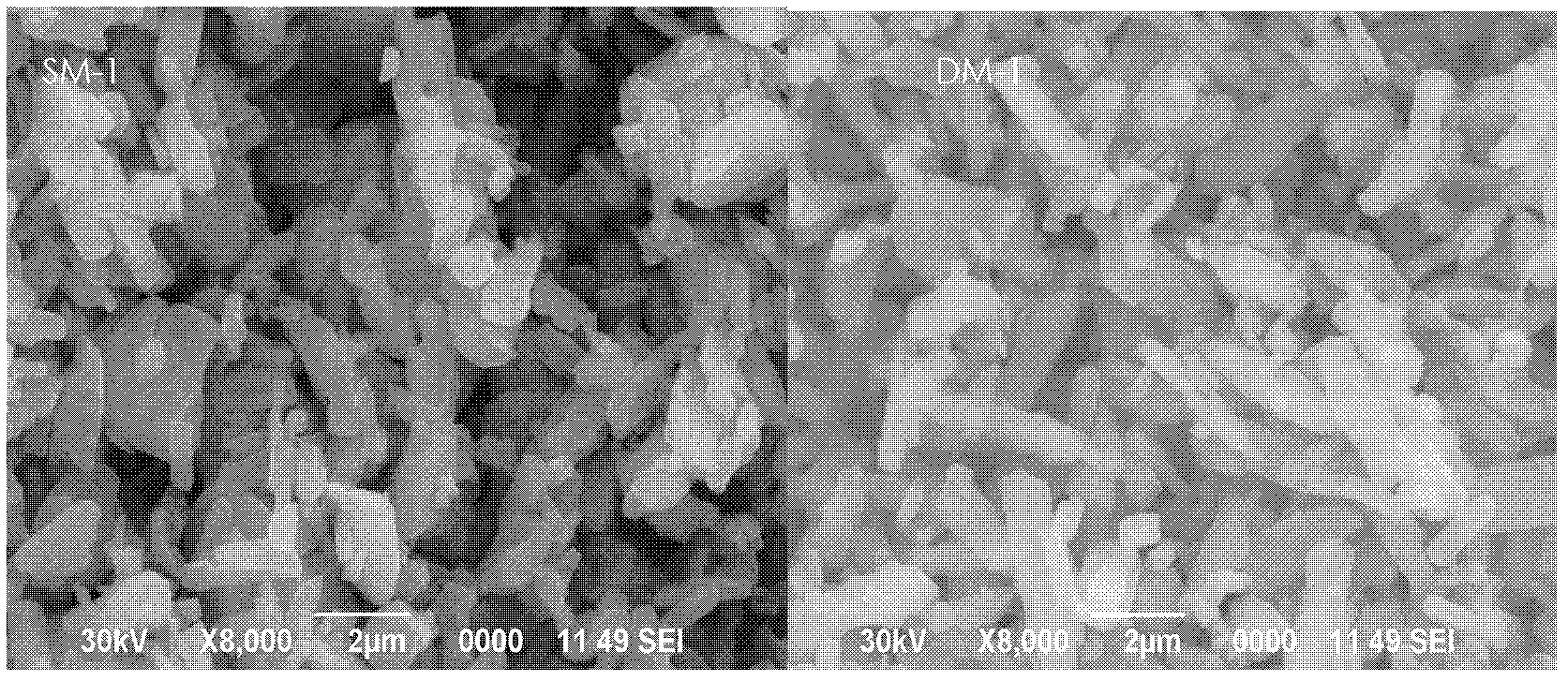

A negative electrode active material, lithium ion battery technology, applied in chemical instruments and methods, inorganic chemistry, titanium compounds, etc., can solve the problems of uncontrollable material morphology, high energy consumption, affecting the electrochemical performance of materials, etc. The effect of migration, good rate performance and excellent cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

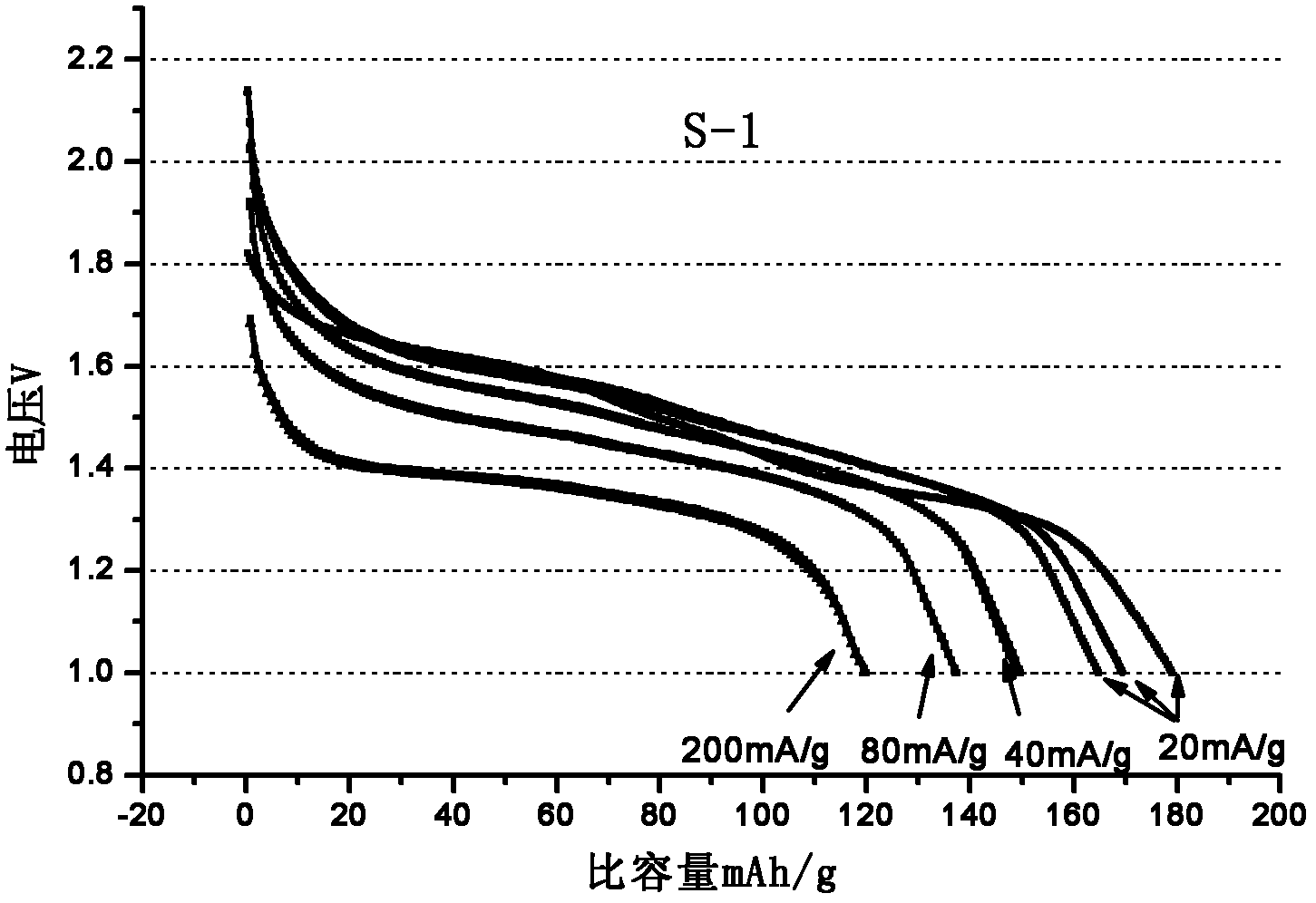

Examples

Embodiment 1

[0031] 1) Configuration solution A: Add 35.16g alkoxy titanium (AR), 250ml isopropanol (AR), 10.5ml glacial acetic acid (AR) and 4mL hydrochloric acid (AR) into the Erlenmeyer flask in turn; solution B: add 4.452 g sodium carbonate dissolved in 13.356 g deionized water;

[0032] 2) Mix the solution B and solution A obtained in 1) under stirring conditions, the stirring speed is 500r / min, the temperature is 20°C, and the dropping speed is controlled by a constant flow pump. After the dropping is completed, continue stirring for 1 hour to stop Stir and let stand for 20 hours;

[0033] 3) Dry the standing product obtained in 2) (100°C), and then bake at 800°C for 20 hours;

[0034] 4) Perform a proton exchange reaction on the roasted product obtained in 3), using a 1.2M hydrochloric acid solution at a ratio of 10g / L, and replace the hydrochloric acid every 24 hours. After repeating three times, wash the product with deionized water until there is no chloride ion present ;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com