Powder spraying, refining and calcium removing method used for aluminium alloy material

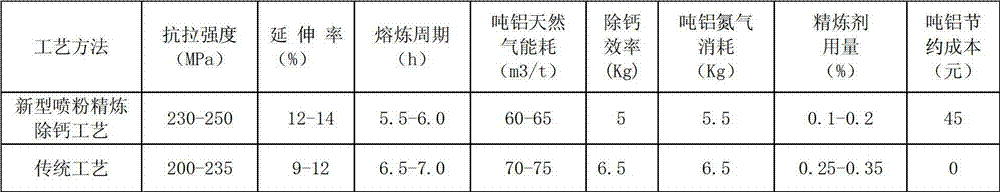

A technology of aluminum alloy materials and powder spraying, which is applied in the field of powder spraying, refining and decalcification of aluminum alloy materials, can solve the problems of undiscovered open patent documents for decalcification of aluminum alloy materials, poor quality of aluminum alloys, serious pollution, etc., and achieve shortening of smelting The effect of time, stable performance and high alloy quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

[0020] A method for decalcifying aluminum alloy materials by powder spraying and refining, the specific steps are as follows:

[0021] (1) Weigh the refining agent and decalcifying agent according to 0.1%-0.2% of the weight of the aluminum liquid. The weight percentage of the decalcifying agent in the refining agent is 20-50%. Pour the refining agent and decalcifying agent into a mechanical stirrer and stir for 5 minutes , the refining agent and calcium remover are all in powder form;

[0022] (2) After the stirring is completed, dry the mixture of refining agent and decalcifying agent in a constant temperature preheating drying oven at a temperature of 200-250°C for 3-4 hours;

[0023] (3) When the temperature of the molten aluminum is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com