Black polyester short fiber production system

A polyester staple fiber and production system technology, which is applied in the production of complete sets of equipment for artificial threads, textiles and papermaking, and the melting of filament raw materials. It can solve the problems of high price of masterbatch, large amount of masterbatch added, and high production cost. Achieve the effects of avoiding secondary coagulation, reducing production costs, and uniform and stable hue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

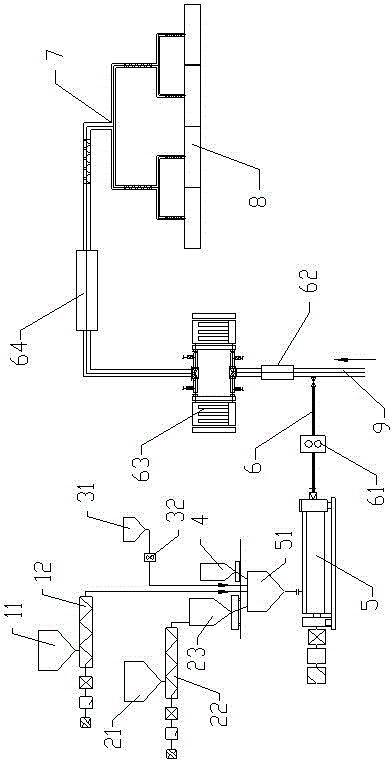

[0020] see figure 1 , a kind of black polyester staple fiber production system that the present invention relates to, it comprises polyester chips adding device, carbon black adding device, dispersant adding device, solid phase additive adding device and co-rotating twin-screw extruder 5, described poly Ester chip adding device, carbon black adding device, dispersant adding device and solid-phase additive adding device feed co-rotating twin-screw extruder 5 simultaneously, and described polyester chip adding device comprises polyester chip hopper 11 and polyester chip Chip single-screw feeder 12, said carbon black adding device comprises carbon black hopper 21, carbon black single-screw feeder 22 and carbon black metering device 23, and said dispersant adding device comprises dispersant hopper 31 and liquid phase additive Metering injection device 32, said solid-phase additive adding device comprises solid-phase additive metering adding device 4, the feed end of described co-r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com