Fervent material output machine

A technology for output machines and materials, applied in conveyors, transportation and packaging, lighting and heating equipment, etc., can solve problems such as low reliability, increased wear, automatic tensioning structure of conveying steel belts, etc., to achieve accurate transmission and reliable operation , Save the effect of automatic tensioning device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

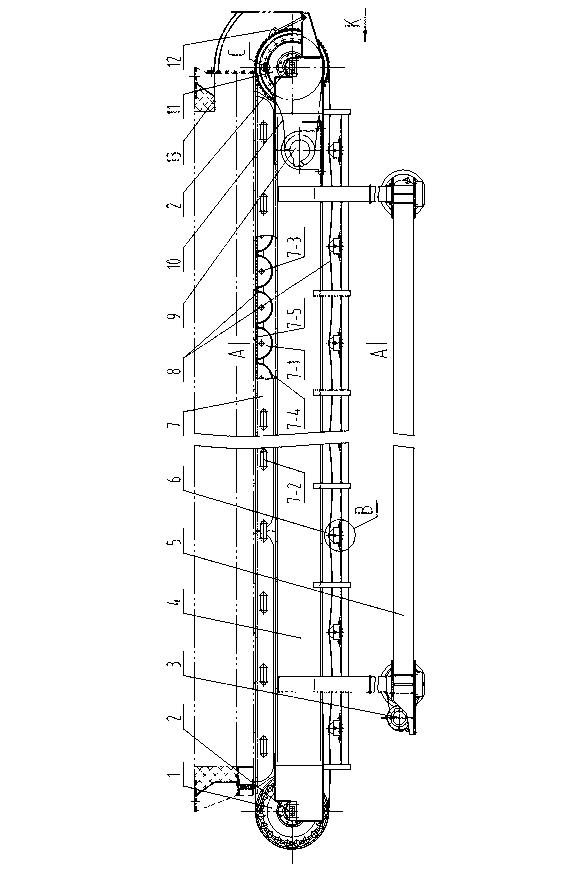

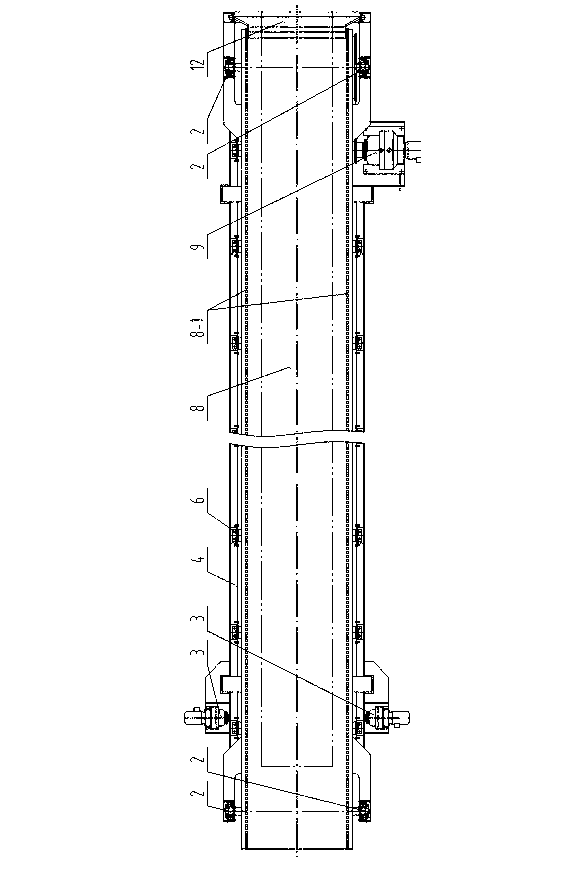

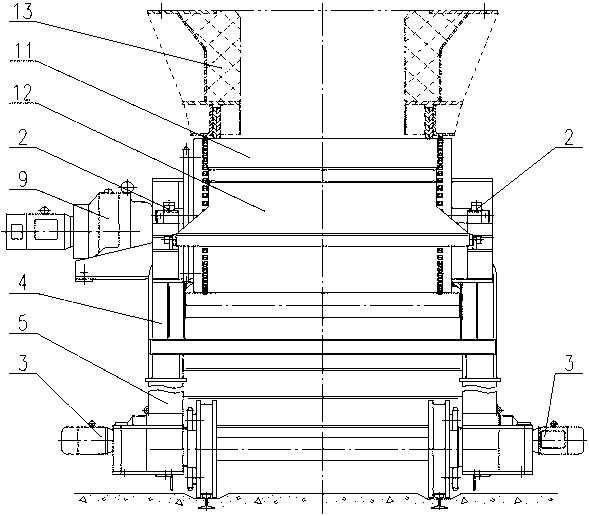

[0039] see figure 1 , figure 2 and Figure 11 , in order to solve the problem that the conveying steel belt in the prior art must be tensioned by an automatic tensioning device with a complex structure and the conveying steel belt cannot bear the impact of a large coke block, etc., a corresponding invention design has been carried out.

[0040] The design concept of the present invention is to include a body 4, a shaft seat 2, a cylindrical driving shaft 11, a cylindrical passive shaft 1, a heat-resistant conveying steel belt 8, a steel belt driving machine 9, a water-filled bed 7 and a plurality of Roller 6. A pair of shaft seats 2 are arranged at both ends of the body 4, and the shaft seats 2 are adjustable shaft seats. A cylindrical driving shaft 11 is installed on a pair of shaft seats 2 at one end, a cylindrical driven shaft 1 is installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com