High-efficiency electronic igniter

An electronic igniter and high-efficiency technology, which is applied in the direction of ignition, combustion ignition, and combustion method using electric sparks, can solve the problems of short life, inconvenient ignition, low manufacturing cost, etc., and achieve improved product performance and wide application range. , the effect of low input voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with specific embodiment and accompanying drawing, technical scheme of the present invention is described further:

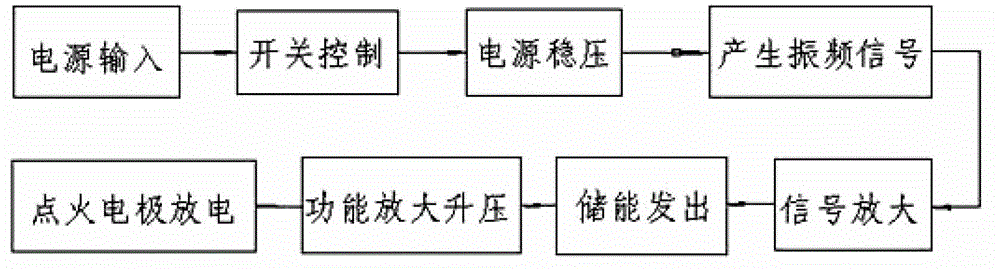

[0019] like figure 1 as shown, figure 1 is a schematic block diagram of the circuit design implementation. The circuit is composed of circuit blocks such as power input, switch control, power supply voltage stabilization, vibration frequency signal generation, signal amplification, energy storage emission, function amplification boost, ignition electrode discharge and other circuit blocks to form a complete circuit.

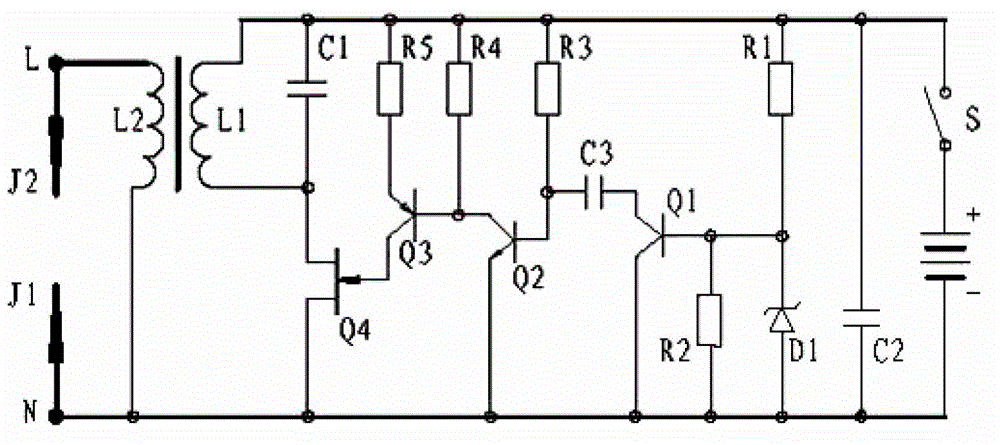

[0020] like figure 2 As shown, the power input is powered by a DC 3-6V battery or an AC regulated power supply; the switch control is to control the power on and off through the switch S to achieve ignition, or the switch circuit to achieve automatic ignition; the power supply is stabilized by capacitor C2, Resistor R1, resistor R2, and rectifier diode D1 form a voltage stabilizing circuit; the vibration frequency si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com