Method for testing TTT (Time,Temperature,Transformation) curve

A technology of curves and test fluids, applied in the direction of investigation phase/state change, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

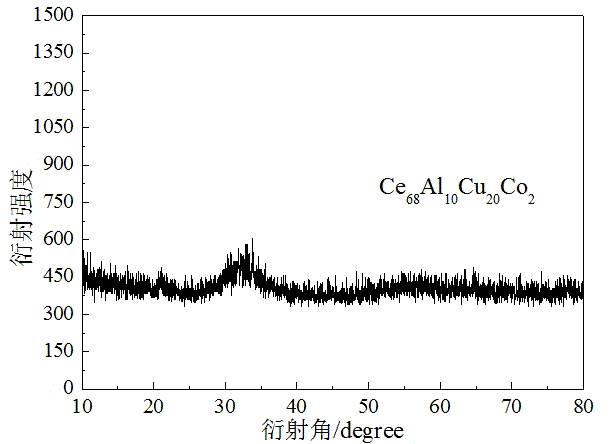

[0031] 1. Use a blade to scrape an appropriate amount of powder from the amorphous rod;

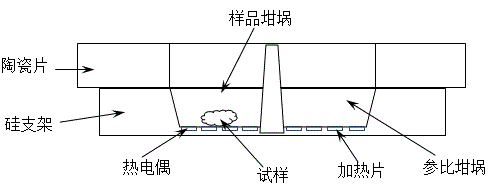

[0032] 2. Select the appropriate sensor according to actual needs. The sensor model used here is XI 400. Use a soft thin copper wire to dip a small amount of silicone oil and apply it to the test area of the sensor to increase the thermal contact area;

[0033] 3. Under the optical microscope, select a micron-sized sample and place it precisely in the center of the sensor test area;

[0034] 4. Heat the material to melt on Flash DSC 1, and confirm that its melting point is 365.7°C and its liquidus temperature is 440°C;

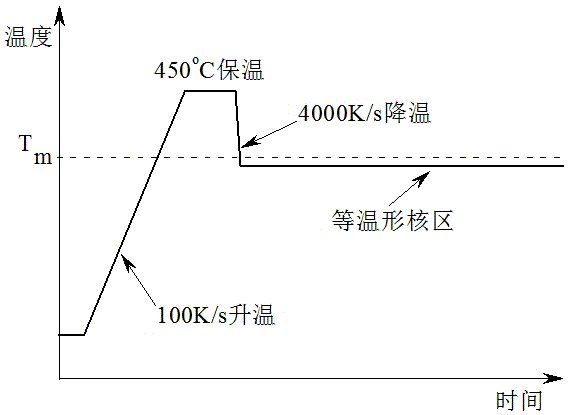

[0035] 5. Take another particle of similar size and repeat step 3, heat to 450°C and keep it warm for 0.5s to make the temperature and composition uniform;

[0036] 6. Rapidly cool down the liquid droplets at a rate of 4,000K / s to 405°C and keep warm. When the isotherm curve shows an exothermic peak, it is the starting point of nucleation, and the incubation period is ...

Embodiment 2

[0040] 1. Use a blade to scrape an appropriate amount of powder from the block Sn;

[0041] 2. Select the appropriate sensor according to actual needs. The sensor model used here is XI 400. Use a soft thin copper wire to dip a small amount of silicone oil and apply it to the test area of the sensor to increase the thermal contact area;

[0042] 3. Under the optical microscope, select a micron-sized sample and place it precisely in the center of the sensor test area;

[0043] 4. Heat the material to melt on Flash DSC 1, and determine its melting point to be 232°C;

[0044] 5. Take another particle of similar size and repeat step 3, heat to 350°C and hold for 0.5s to make the temperature uniform;

[0045] 6. Rapidly cool down the liquid droplets at a rate of 4,000K / s to 160°C and keep warm. When the isotherm curve shows an exothermic peak, it is the starting point of nucleation, and the incubation period is determined to be 85.8s by tangential extrapolation;

[0046] 7. Sele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com