Lightning stroke-resistant optical fibre composite overhead ground wire

An overhead ground wire, optical fiber composite technology, applied in power cables, electrical components, circuits, etc., can solve the problems of threats, easy burnout, aging of aluminum alloy wires, etc., achieve high tensile strength and melting point, ensure normal operation, The effect of good anti-lightning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

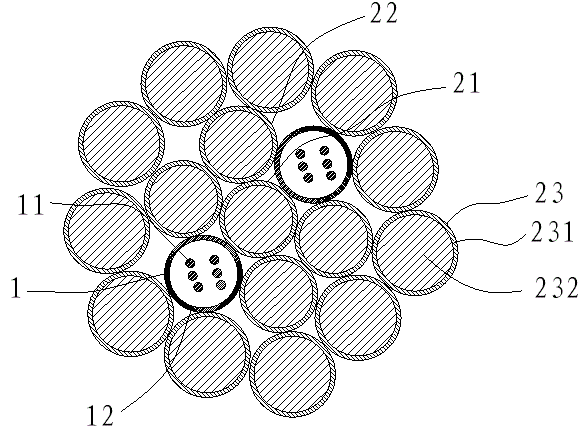

[0031] refer to figure 1 , a lightning-resistant optical fiber composite overhead ground wire, including an optical unit 1 with a stainless steel tube 12 as a sleeve, and an aluminum-clad steel wire. The optical unit 1 includes an optical fiber 11, and the optical fiber 11 is located in the stainless steel tube 12. The aluminum-clad steel wire and the light unit 1 form a stranded structure, and the stranded structure includes a central layer, a first layer, and a second layer, and the central layer has an aluminum-clad steel wire-21, and the first layer includes The aluminum-clad steel wire two 22 and the light unit 1 are divided into four aluminum-clad steel wires 22 and two light units 1. The light units 1 are symmetrically distributed with respect to the central layer, and the second layer includes three aluminum-clad steel wires. 23. The second layer of aluminum-clad steel wires 23 is eleven. The aluminum-clad steel wires are composed of aluminum layers 231 and steel wires...

Embodiment 2

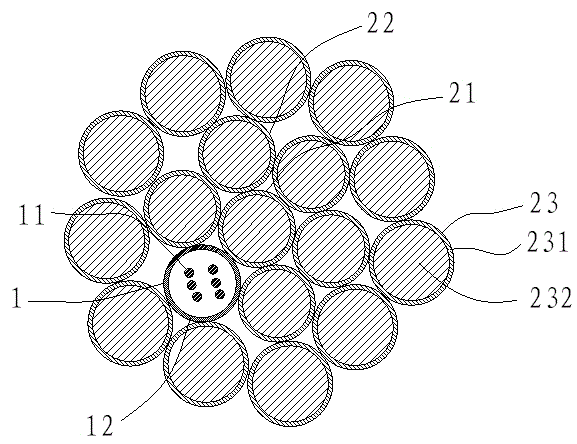

[0035] Such as figure 2 As shown, the difference between this embodiment and the first embodiment is that the first layer includes five aluminum-clad steel wires 22 and one light unit 1 .

Embodiment 3

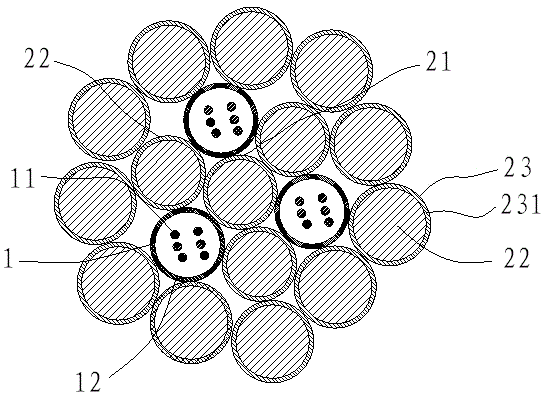

[0037] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 and Embodiment 2 is that the first layer includes three aluminum-clad steel wires 22 and three optical units 1, and the optical units 1 and the aluminum-clad steel Line two 22 cross distribution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com