High-strength molten-zinc-plated steel sheet having excellent bendability and weldability, and process for production thereof

A technology for hot-dip galvanized steel sheet and weldability, which is applied in the field of high-strength hot-dip galvanized steel sheet and its manufacture, can solve the problems of reduced workability and steel sheet fracture, and achieves the effect of improving weldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

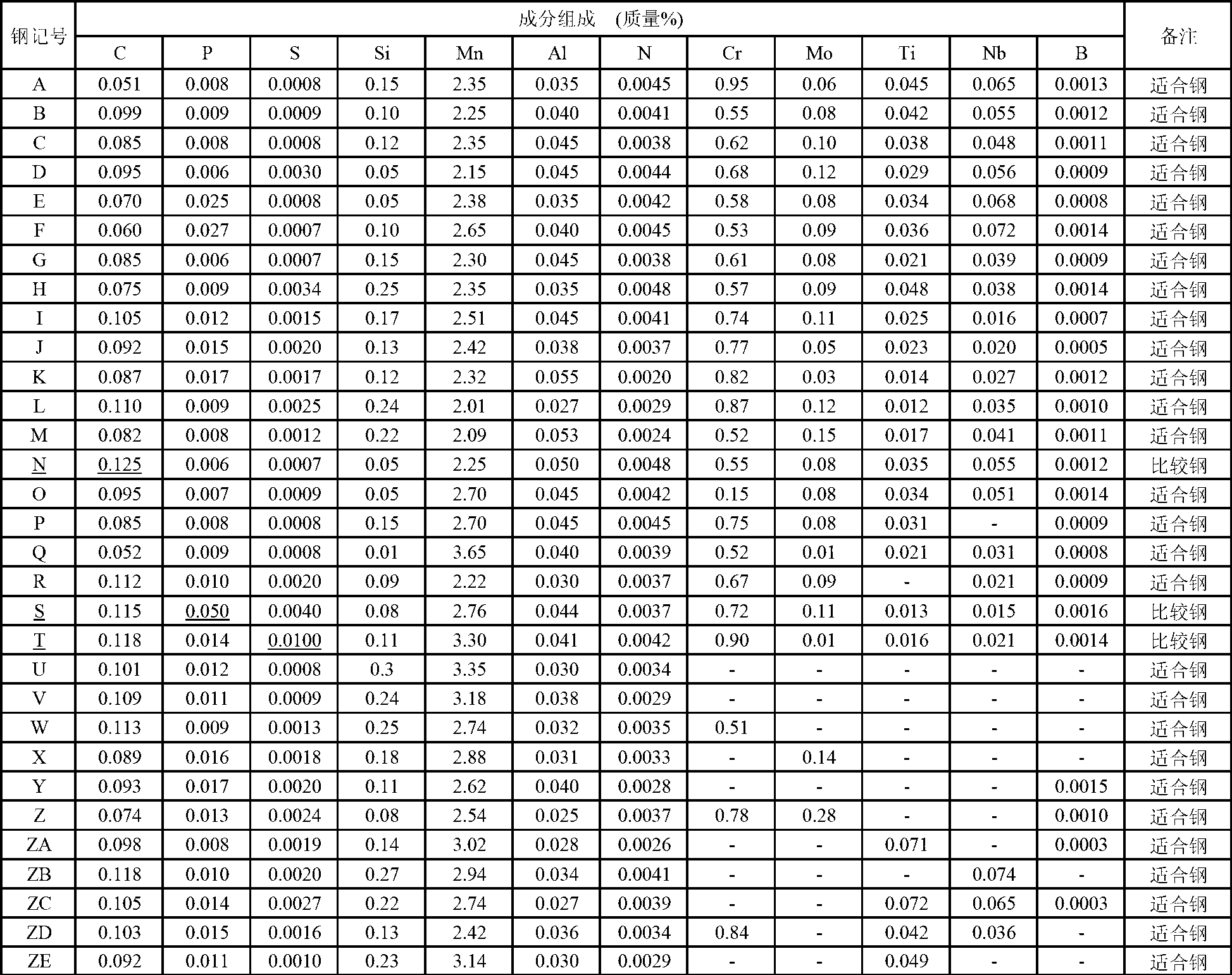

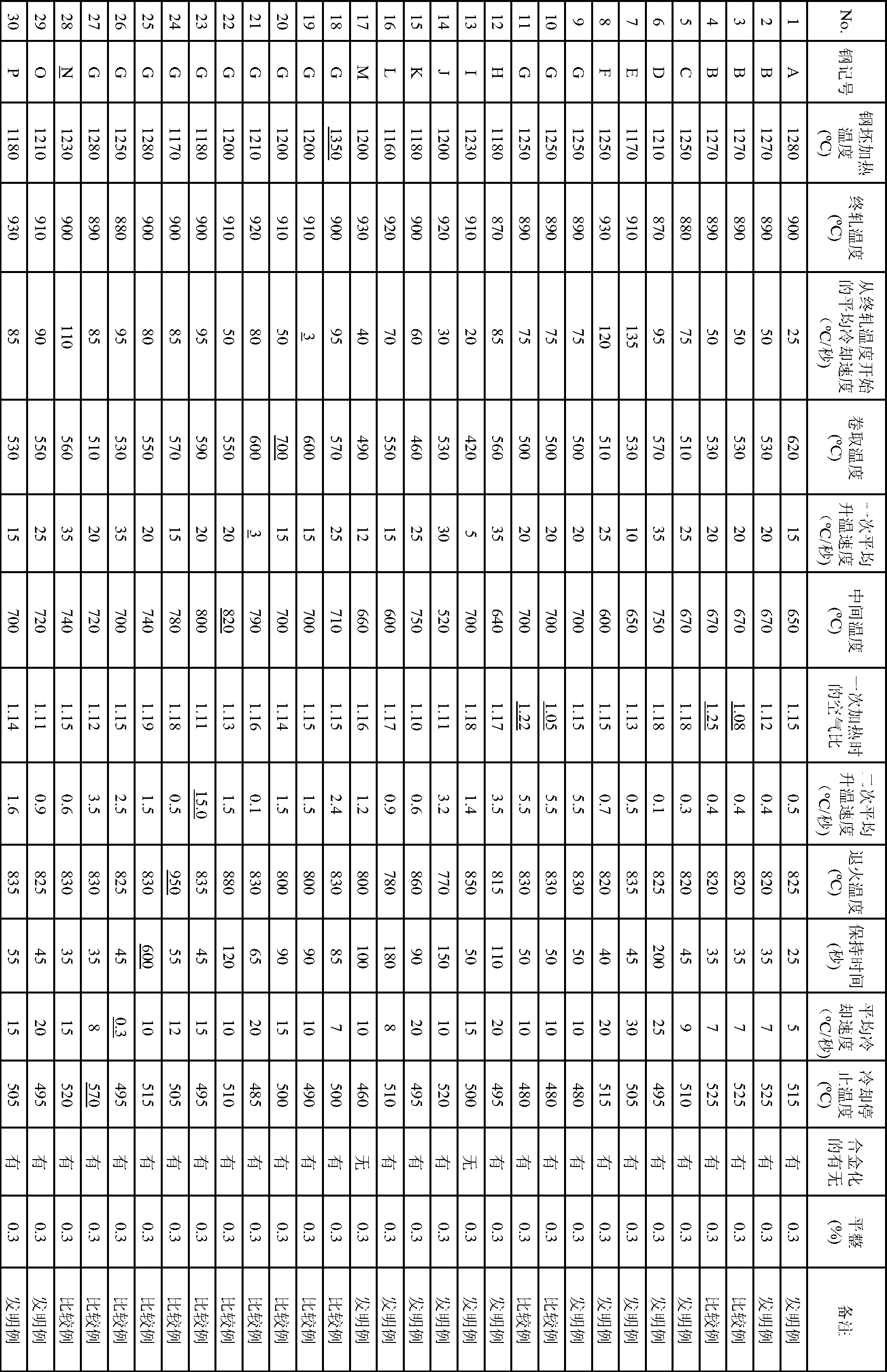

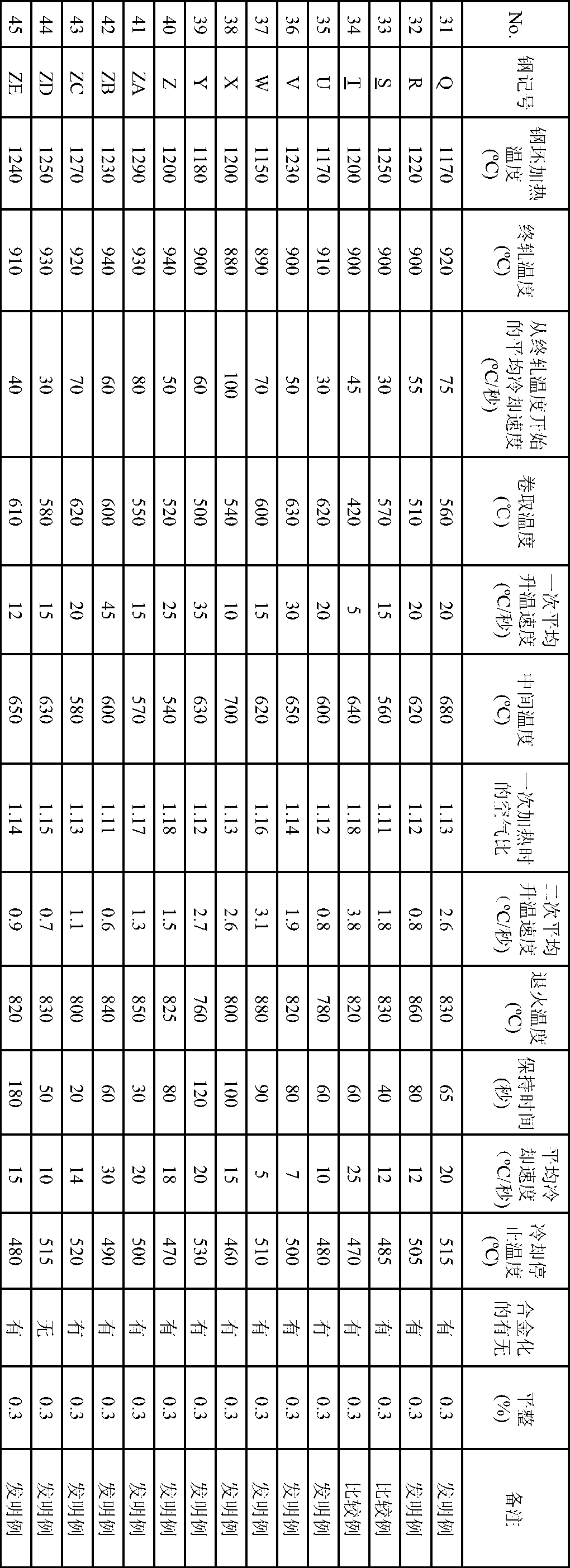

[0155] The steel with the composition shown in Table 1 is smelted. Under the conditions shown in Tables 2-1 and 2-2, slab heating, hot rolling, coiling, cold rolling with a rolling rate of 50%, and continuous Annealing and plating treatment, the thickness of the manufactured plate is 2.0mm, and the coating adhesion per single side is 45g / m 2 Hot-dip galvanized steel sheet and alloyed hot-dip galvanized steel sheet. It should be noted that the rolling reduction rate during cold rolling was all 50%. In addition, the air ratio in the furnace during continuous annealing was set to the air ratio shown in Tables 2-1 and 2-2 during the primary temperature rise, and the range of 0.8 to 1.0 after the secondary temperature rise.

[0156] With respect to the hot-dip galvanized steel sheet and galvannealed steel sheet obtained in this way, the following material tests were performed to examine the material properties.

[0157] The results are shown in Tables 3-1, 3-2, and Table 4.

[0158] It ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com