Preparation method and brewing method of ultrafine white tea

An ultra-fine, white tea technology, applied in the direction of tea processing before extraction, can solve the problems of low efficiency, difficult to fully analyze functional components, small contact area, etc., to expand the unit area, reduce the loss of activity and flavor, and improve the resistance effect of tumor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

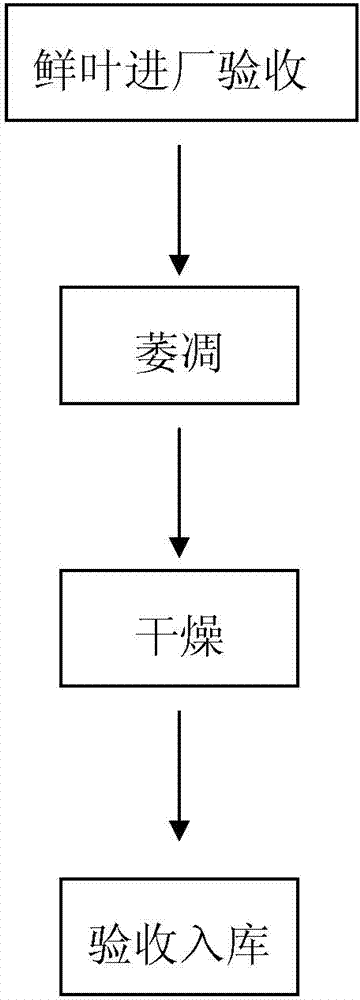

[0021] Embodiment 1: A kind of preparation method of superfine white tea, it utilizes existing airflow superfine pulverization equipment, controls preparation temperature at 20 ℃, prepares according to the following steps:

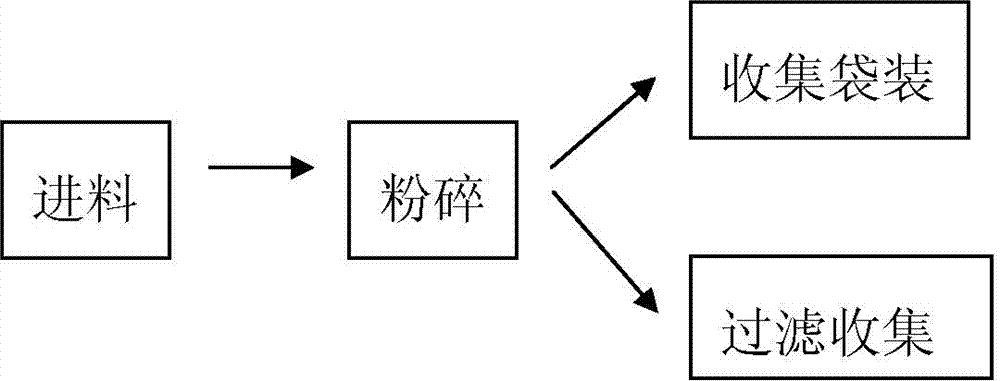

[0022] 1) Feeding: Pour the finished white tea into the feeding system of the airflow ultrafine pulverization equipment, and transport it to the pulverization host through the conveyor belt;

[0023] 2) Pulverization: The rated power of the pulverization is 80KW, and the gas volume is 11 m 3 / min, working air pressure 1.1MPa; in the crushing machine, the finished white tea is crushed into superfine white tea by adjusting the number of wheels to adjust the particle size, and the white tea that does not meet the particle size requirement is returned to the crushing chamber by the classifier to continue crushing;

[0024] 3) Collecting and bagging: the ultra-fine white tea that reaches the specified particle size passes through the classifier and collects the...

Embodiment 2

[0026] Embodiment 2: A kind of preparation method of ultrafine white tea, it utilizes existing airflow ultrafine pulverization equipment, controls preparation temperature at 15 ℃, prepares according to the following steps:

[0027] 1) Feeding: Pour the finished white tea into the feeding system of the airflow ultrafine pulverization equipment, and transport it to the pulverization host through the conveyor belt;

[0028] 2) Pulverization: The rated power of the pulverization is 70KW, and the gas volume is 9m 3 / min, the working air pressure is 0.9MPa; in the crushing machine, the finished white tea is crushed into ultra-fine white tea by adjusting the number of wheels to adjust the particle size, and the white tea that does not meet the particle size requirement is returned to the crushing chamber by the classifier to continue crushing;

[0029] 3) Collecting and bagging: the ultra-fine white tea that reaches the specified particle size passes through the classifier and collec...

Embodiment 3

[0031] Embodiment 3: A kind of preparation method of superfine white tea, it utilizes existing airflow superfine pulverization equipment, controls preparation temperature at 10 ℃, prepares according to the following steps:

[0032] 1) Feeding: Pour the finished white tea into the feeding system of the airflow ultrafine pulverization equipment, and transport it to the pulverization host through the conveyor belt;

[0033] 2) Pulverization: The rated power of the pulverization is 60KW, and the gas volume is 8m 3 / min, the working air pressure is 0.7MPa; in the crushing machine, the finished white tea is crushed into superfine white tea by adjusting the number of wheels to adjust the particle size, and the white tea that does not meet the particle size requirement is returned to the crushing chamber by the classifier to continue crushing;

[0034] 3) Collecting and bagging: the ultra-fine white tea that reaches the specified particle size passes through the classifier and collect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com