Preparation method of burley tobacco shreds for cigarettes

A technology of shredded burley tobacco and burley tobacco, which is applied in the field of preparation of shredded burley tobacco for cigarettes, can solve the problems of expanding the application range of shredded burley tobacco and poor smoking quality, and achieve good smoking quality, reduced miscellaneous gas, and improved quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

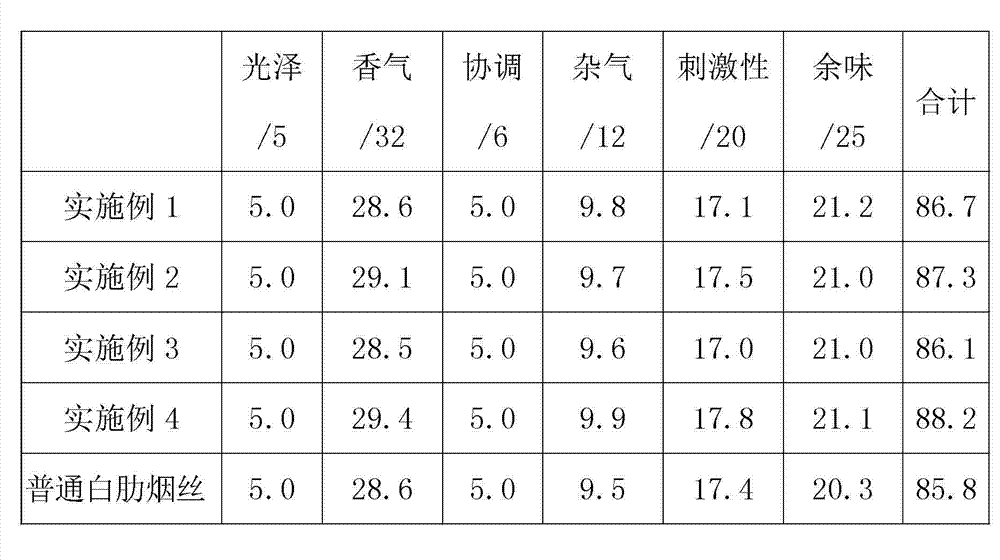

Examples

Embodiment 1

[0018] The invention discloses a method for preparing shredded burley tobacco for cigarettes. The burley tobacco is soaked in soaking solution for 30 minutes under the condition of 45 DEG C, then dehydrated and dried, cut into shreds, and finally dried and puffed. The soaking solution is prepared by the following method: extract the grapes with 5 times (weight) 65% edible alcohol, concentrate them into an extract with a relative density of 1.1, and add glutamic acid at 0.5% of the weight of the extract , and finally diluted 5 times with water. The extraction is reflux extraction, the extraction temperature is 70° C., the extraction time is 2 hours, and the number of extractions is 2 times. There is also a step of adding maltose and glutamic acid after the sliced shreds, the weight ratio of maltose and glutamic acid is 2:1, and the total amount of maltose and glutamic acid accounts for 4.5% of the weight of the sliced Burley tobacco sheet.

Embodiment 2

[0020] The invention discloses a method for preparing shredded burley tobacco for cigarettes. The burley tobacco is soaked in soaking liquid for 25 minutes under the condition of 60° C., then dehydrated and dried, sliced and shredded, and finally dried and puffed. The soaking solution is prepared by the following method: extract the cherries with 10 times the amount (weight) of 55% edible alcohol, concentrate them into an extract with a relative density of 1.5, add lysine according to 3% of the weight of the extract, Finally diluted 12 times with water. The extraction is reflux extraction, the extraction temperature is 80° C., the extraction time is 3 hours, and the extraction frequency is 1 time. There is also a step of adding galactose and lysine after the sliced silk, the weight ratio of galactose and lysine is 1:1, and the total amount of galactose and lysine accounts for 10% of the weight of the Burley tobacco sheet after slicing. 4%.

Embodiment 3

[0022] The invention discloses a method for preparing shredded burley tobacco for cigarettes. The burley tobacco is soaked in soaking liquid for 35 minutes under the condition of 40 DEG C, then dehydrated and dried, sliced and shredded, and finally dried and puffed. The soaking solution is prepared by the following method: after extracting grapes and cherries (weight ratio 1:1) with 8 times (weight) 60% alcohol, concentrate them into an extract with a relative density of 1.25, press the extract Add glutamic acid to 1% of the paste weight, and finally dilute 10 times with water. The extraction is reflux extraction, the extraction temperature is 60° C., the extraction time is 1 hour, and the extraction times are 3 times. There is also the step of adding galactose and lysine after the sliced silk, the weight ratio of galactose and lysine is 1.5:1, and the total amount of galactose and lysine accounts for 10% of the Burley tobacco sheet weight after slicing. 4.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com