Rectification device and process for purifying ethyl difluoroacetate efficiently

A high-efficiency technology of ethyl difluoroacetate, applied in the field of high-efficiency purification of ethyl difluoroacetate rectification equipment, can solve the problems of lack of preparation research on fluorine-containing compounds, unsuitable for industrial applications, waste of raw materials and purity, and achieve low operating costs , Low equipment cost, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

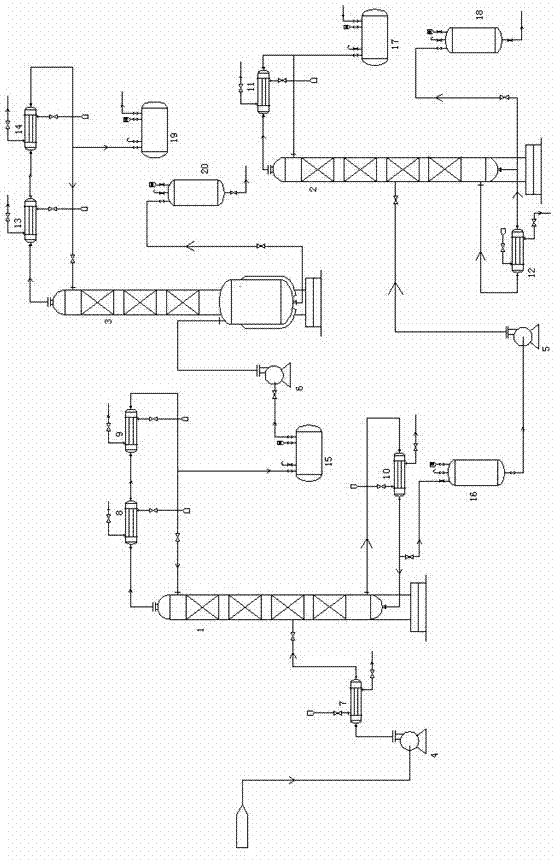

Image

Examples

Embodiment 1

[0017] Product feed content 90%:

[0018] Feed material at bubble point of light removal tower 1, processing capacity: 30kg / hr, the fourth heat exchanger 10 turns on low-pressure steam, when condensate distills out from the top of light removal tower 1, the top of the tower starts to fully reflux, and when the temperature at the top of the tower reaches At 45-50°C, the intermediates are mined, and the second feed pump 5 is started to feed the finished product tower 2. The sixth heat exchanger 12 turns on the low-pressure steam, and when condensate distills out from the top of the finished product tower 2, the top of the tower begins to reflux, and when the temperature at the top of the tower reaches 98-99°C, the finished product ethyl difluoroacetate is collected, with a content of 99.97% . Only key control points are listed, and other conditions are detailed in the specific implementation section, the same below.

Embodiment 2

[0020] Product feed content 96.67%:

[0021] Feed material at bubble point of light removal tower 1, processing capacity: 50kg / hr, the fourth heat exchanger 10 turns on low-pressure steam, when condensate distills out from the top of light removal tower 1, the top of the tower starts to fully reflux, and when the temperature at the top of the tower reaches At 45-50°C, the intermediates are mined, and the second feed pump 5 is started to feed the finished product tower 2. The sixth heat exchanger 12 turns on the low-pressure steam, and when condensate distills out from the top of the finished product tower 2, the top of the tower begins to reflux, and when the temperature at the top of the tower reaches 98-99°C, the finished product ethyl difluoroacetate is collected, with a content of 99.98% .

Embodiment 3

[0023] Product feed content 95%:

[0024]Feed material at bubble point of light removal tower 1, processing capacity: 70kg / hr, the fourth heat exchanger 10 turns on low-pressure steam, when condensate distills out from the top of light removal tower 1, the top of the tower starts to fully reflux, and when the temperature at the top of the tower reaches At 45-50°C, the intermediates are mined, and the second feed pump 5 is started to feed the finished product tower 2. The sixth heat exchanger 12 turns on the low-pressure steam, and when condensate distills out from the top of the finished product tower 2, the top of the tower begins to reflux, and when the temperature at the top of the tower reaches 98-99°C, the finished product ethyl difluoroacetate is collected, with a content of 99.95% .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com