Nano-composite catalyst TiO2-gamma-AlOOH and preparation method as well as application thereof

A nano-composite and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of low utilization of sunlight, toxic intermediate products, slow degradation rate, etc., and achieve simple operation. , low cost, the effect of reducing the processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A nanocomposite catalyst TiO 2 -γ-AlOOH, that is, using γ-AlOOH as a carrier to support TiO 2 The nanocomposite catalyst made of TiO 2 The loading amount is according to its mass ratio relative to the γ-AlOOH carrier, that is, TiO 2 : γ-AlOOH carrier is 10:100.

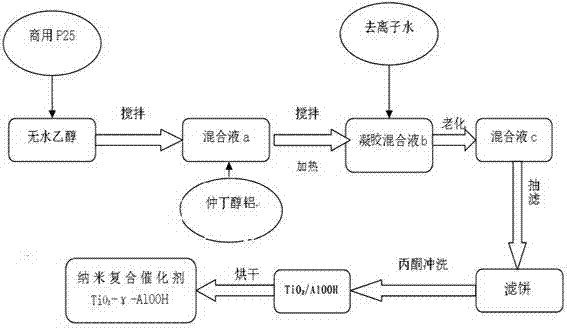

[0032] Above-mentioned a kind of nanocomposite catalyst TiO 2 - the preparation method of γ-AlOOH, its preparation process is as figure 1 As shown, first add commercial titanium dioxide, that is, P25, into absolute ethanol, stir and mix evenly to obtain a mixed solution a, add aluminum sec-butoxide to the mixed solution a, heat and stir, and add a small amount of deionized water to form a gel that is mixed Liquid b, the obtained mixed liquid b is aged to obtain mixed liquid c, the obtained mixed liquid C is subjected to suction filtration, and the filter cake obtained is washed with acetone to obtain TiO 2 / AlOOH, further drying to obtain the nanocomposite catalyst TiO 2 -γ-AlOOH, specifically comprising ...

Embodiment 2

[0038] A nanocomposite catalyst TiO 2 -γ-AlOOH, that is, using γ-AlOOH as a carrier to support TiO 2 The nanocomposite catalyst made of TiO 2 The loading amount is according to its mass ratio relative to the γ-AlOOH carrier, that is, TiO 2 : γ-AlOOH carrier is 30:100.

[0039] Above-mentioned a kind of nanocomposite catalyst TiO 2 -The preparation method of γ-AlOOH specifically comprises the following steps:

[0040] (1) Weigh 0.6g of P25 and add it into 8g of absolute ethanol, stir and mix evenly to obtain the mixture a;

[0041] (2) Weigh 5.65g of aluminum sec-butoxide and add it to the mixture a prepared in step (1), heat to 150°C and stir for 3 hours, add 2.5ml of deionized water to obtain the gel mixture b;

[0042] (3), age the gel mixture b obtained in step (2) for 3 hours, filter with suction, and rinse the obtained filter cake with acetone 5 times to obtain TiO 2 / AlOOH;

[0043] (4), finally the TiO obtained in step (3) 2 / AlOOH is placed in a blast drying ov...

Embodiment 3

[0045] A nanocomposite catalyst TiO 2 -γ-AlOOH, that is, using γ-AlOOH as a carrier to support TiO 2 The nanocomposite catalyst made of TiO 2 The loading amount is according to its mass ratio relative to the γ-AlOOH carrier, that is, TiO 2 : γ-AlOOH carrier is 40:100.

[0046] Above-mentioned a kind of nanocomposite catalyst TiO 2 -The preparation method of γ-AlOOH specifically comprises the following steps:

[0047] (1) Add 0.35g of P25 into 3.6g of absolute ethanol, stir and mix evenly to obtain a mixture a;

[0048] (2) Add 2.126g of aluminum sec-butoxide to the mixture a obtained in step (1), heat to 160°C and stir for 2 hours, then add 1.3ml of deionized water to obtain the gel mixture b;

[0049] (3), aging the gel mixture b obtained in step (2) for 3 hours, suction filtering, and rinsing the obtained filter cake with acetone 5 times to obtain TiO 2 / AlOOH ;

[0050] (4), finally the TiO obtained in step (3) 2 / AlOOH is placed in a blast drying oven at a cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com