Halogenless soldering flux for tin and bismuth low-temperature solder wire and preparation method thereof

A flux, halogen-free technology, used in welding equipment, welding media, manufacturing tools, etc., can solve problems such as organic acids or organic halides cannot be effectively volatilized, surface insulation resistance is increased, and solder joint residues are blackened. , to achieve the effect of improving welding activity, high insulation resistance and avoiding blackening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

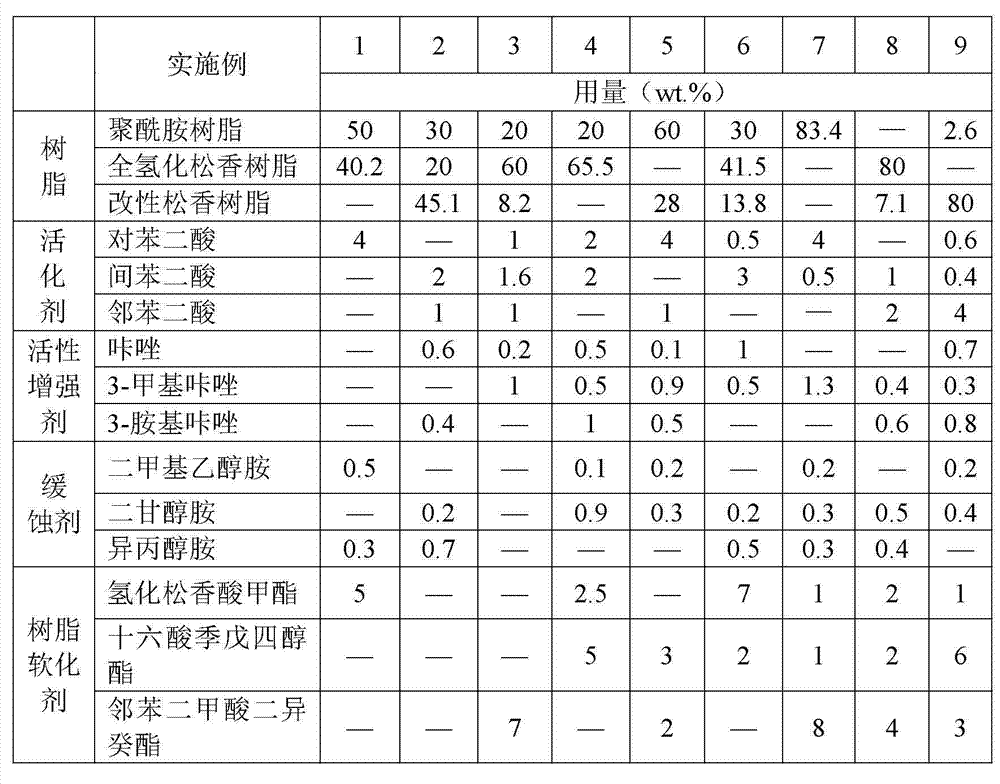

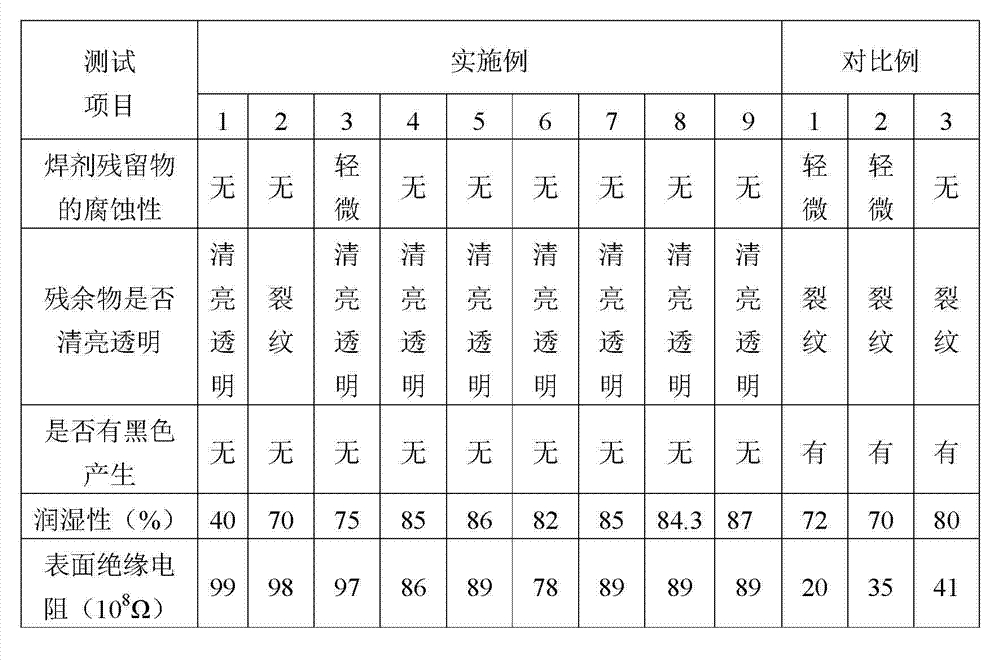

[0021] The present invention will be further described in detail below in conjunction with specific embodiments. The specific formulations of each example are shown in Table 1, and the flux content of the technical solution of the present invention in the solder paste is 1.5~3wt.%, and the metal composition used is 52wt.% and 48wt.%. The flux described in the present invention is compared with the commercially available lead-free flux.

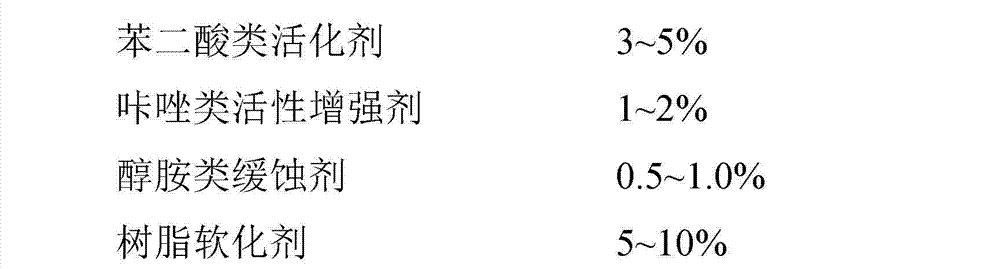

[0022] The preparation method of the halogen-free flux for tin-bismuth low-temperature tin wire is carried out in the following steps according to the ratio in Table 1: (1) add all the resin into the reaction kettle and heat and stir until it is completely melted; (2) at 150~160 Add 3~5wt.% phthalic acid activator and 1~2wt.% carbazole activity enhancer at ℃, and stir for 15~30 minutes to make it evenly mixed to obtain a premix; (3) Add to (2) After adding 0.5~1.0wt.% alcohol amine corrosion inhibitor and 5~10wt.% resin softener to the obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com