Halogen-free flux for high activity tin wire and preparation method thereof

A flux, halogen-free technology, used in welding equipment, welding media, manufacturing tools, etc., can solve the problems of ineffective volatilization, reduced surface insulation resistance, blackening of solder joint residues, etc., to achieve a clear and transparent appearance, The effect of improved welding activity and high insulation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

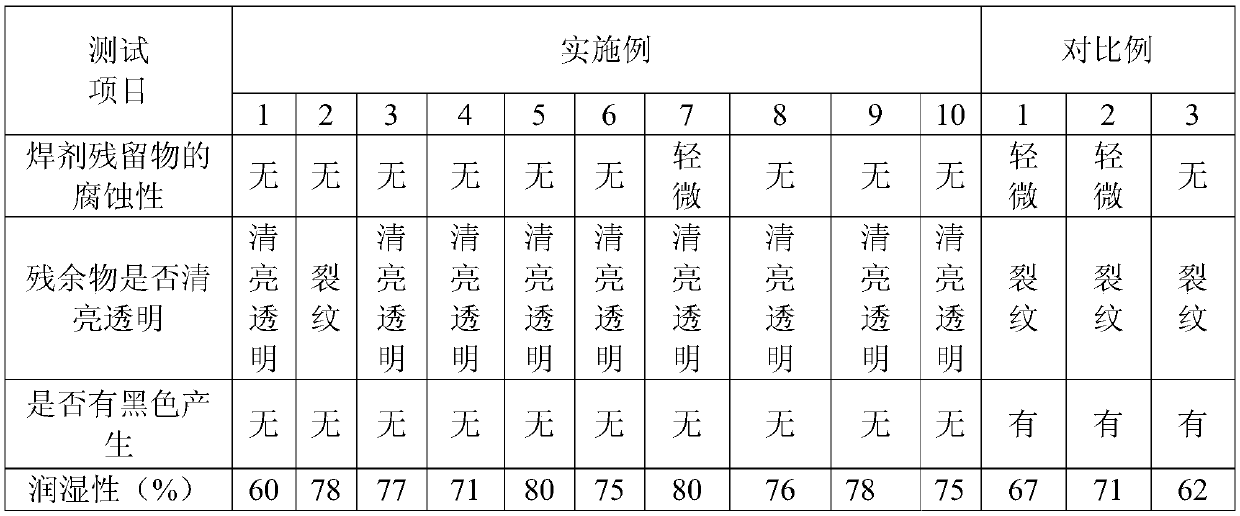

Examples

Embodiment Construction

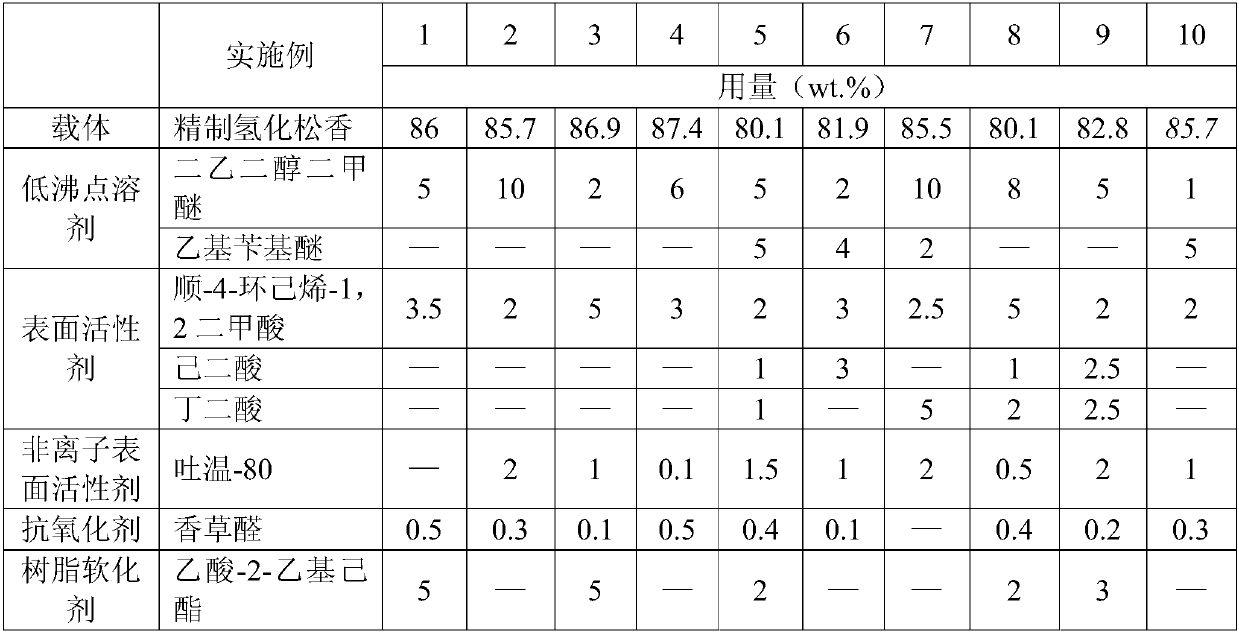

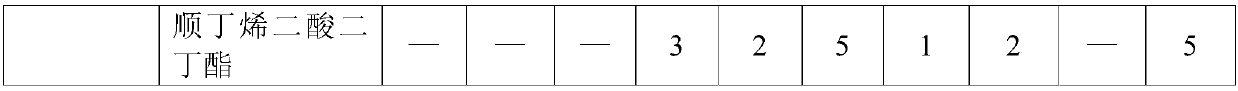

[0016] The present invention will be described in detail below in conjunction with specific embodiments. Specific embodiments are prepared by the following steps with reference to the formula dosage described in Table 1.

[0017] A preparation method of halogen-free flux for highly active tin wire, the method comprising the steps of:

[0018] (1) Add the refined hydrogenated rosin in the formula dosage into the reaction kettle, heat and stir until it melts completely, then raise the temperature in the reaction kettle to 130-150°C, and then add the necessary and non-essential low boiling point solvents and the necessary type in the recipe dosage Mix with optional surfactant and Tween-80 for 15-30 minutes to obtain a premix;

[0019] (2) After adding the formula dosage of vanillin and resin softener to the pre-mixture obtained in step (1), stir for 15-30 minutes and mix evenly to obtain a halogen-free flux for highly active tin wire.

[0020] Table 1 specific embodiment

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com