Preparation method and application of core-shell-structured nickelous hydroxide or hierarchical porous carbon composite material

A carbon composite material and hierarchical porous technology, which is applied in the preparation/purification of carbon, nickel oxide/nickel hydroxide, microsphere preparation, etc., can solve the problems of high preparation cost, low energy density of supercapacitors, and difficult application of supercapacitors, etc. problem, to achieve the effect of improving utilization rate, improving electrochemical performance and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

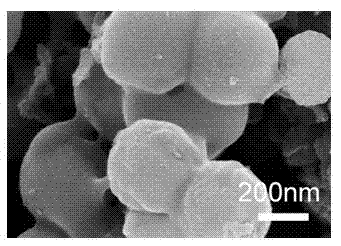

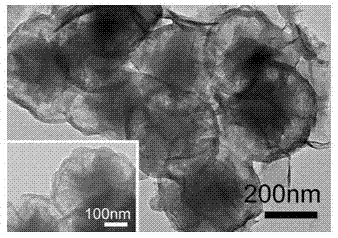

[0027] 0.04 g of self-made hierarchical porous carbon was dispersed in 1 M sulfuric acid solution, heated to 60 °C for acidification for 6 hours, filtered, washed with deionized water until neutral, and dried at 60 °C for 8 hours to obtain acidified hierarchical porous carbon spheres. Disperse 0.04 g of acidified hierarchical porous carbon in 60 ml of deionized water and sonicate for 15 min to fully disperse. Add 0.291 g Ni (NO 3 ) 2 ·6H 2 O, stir for 15 minutes until uniformly dissolved, then add 0.701 g of HMT, and continue stirring for 10 minutes to obtain a mixed solution. Finally, the mixed solution was transferred to a hydrothermal reactor, sealed, and reacted at 80°C for 12 hours; after the hydrothermal reactor was naturally cooled to room temperature, it was filtered, washed and separated with deionized water and absolute ethanol, and dried to obtain hydroxide. Nickel / hierarchical porous carbon composites.

Embodiment 2

[0029] 0.04 g of self-made hierarchical porous carbon was dispersed in 1 M sulfuric acid solution, heated to 60 °C for 6 hours, acidified, filtered, washed with deionized water until neutral, and dried at 60 °C for 8 hours to obtain acidified hierarchical porous carbon spheres. Disperse 0.04 g of acidified hierarchical porous carbon in 60 ml of deionized water and sonicate for 15 min to fully disperse. Add 0.146 g Ni (NO 3 ) 2 ·6H 2 O, stir for 15 minutes until uniformly dissolved, then add 0.351 g of HMT, and continue stirring for 10 minutes to obtain a mixed solution. Finally, the mixed solution was transferred to a hydrothermal reactor, sealed, and reacted at 80°C for 12 hours; after the hydrothermal reactor was naturally cooled to room temperature, it was filtered, washed and separated with deionized water and absolute ethanol, and dried to obtain hydroxide. Nickel / hierarchical porous carbon composites.

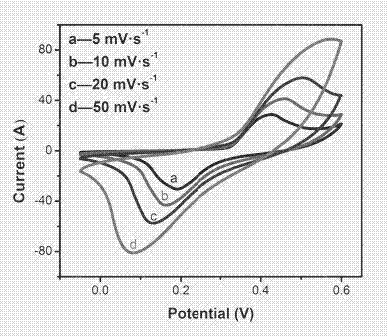

[0030] The nickel hydroxide / hierarchical porous carbon composite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com