Application of low-silicon micro-pore NaA type and NaX type molecular sieves in treatment of low-concentration heavy metal ions

A low-concentration heavy metal and heavy metal ion technology, applied in water/sewage treatment, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve problems such as environmental pollution, inability to remove heavy metal ions, and affect domestic water safety. The effect of low operation and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

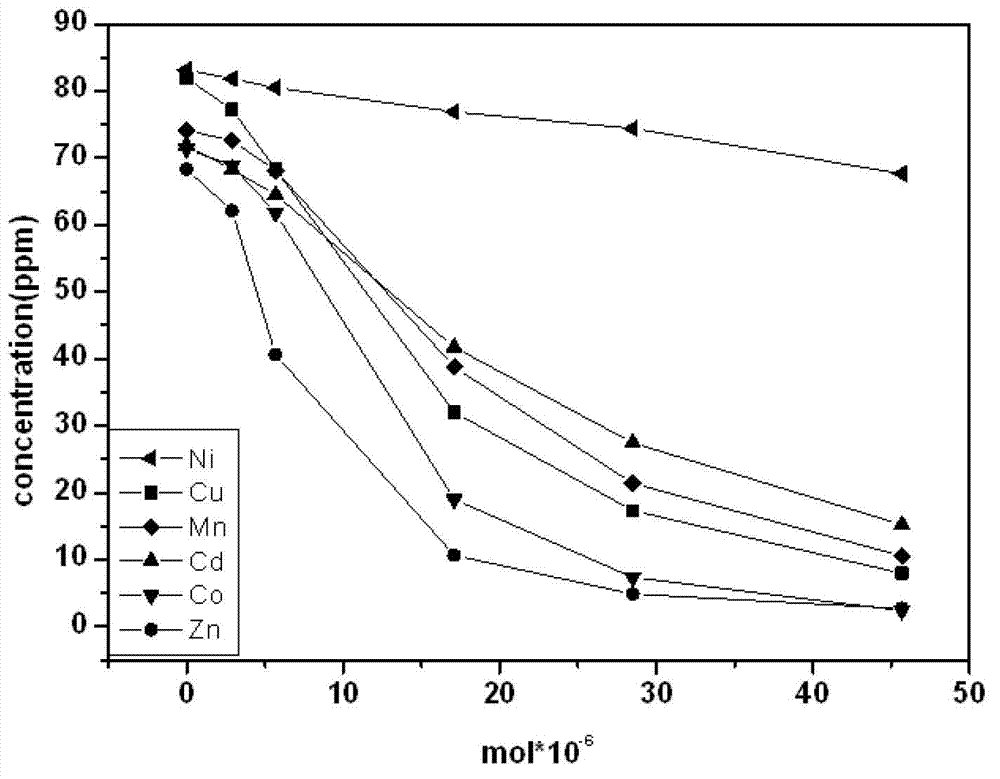

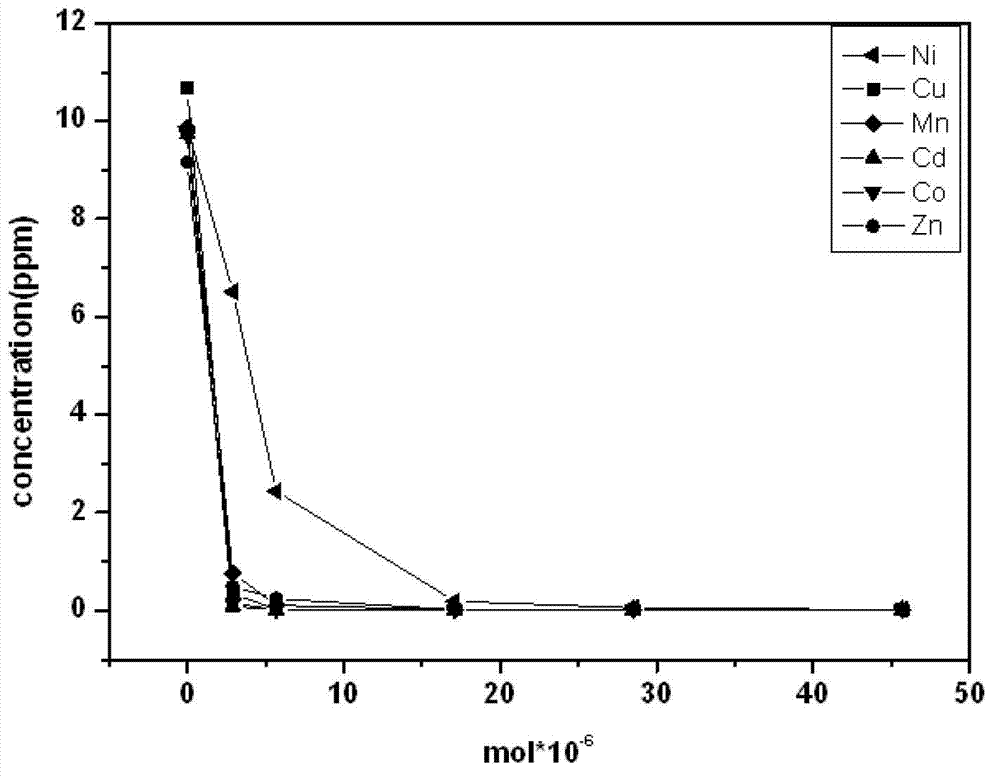

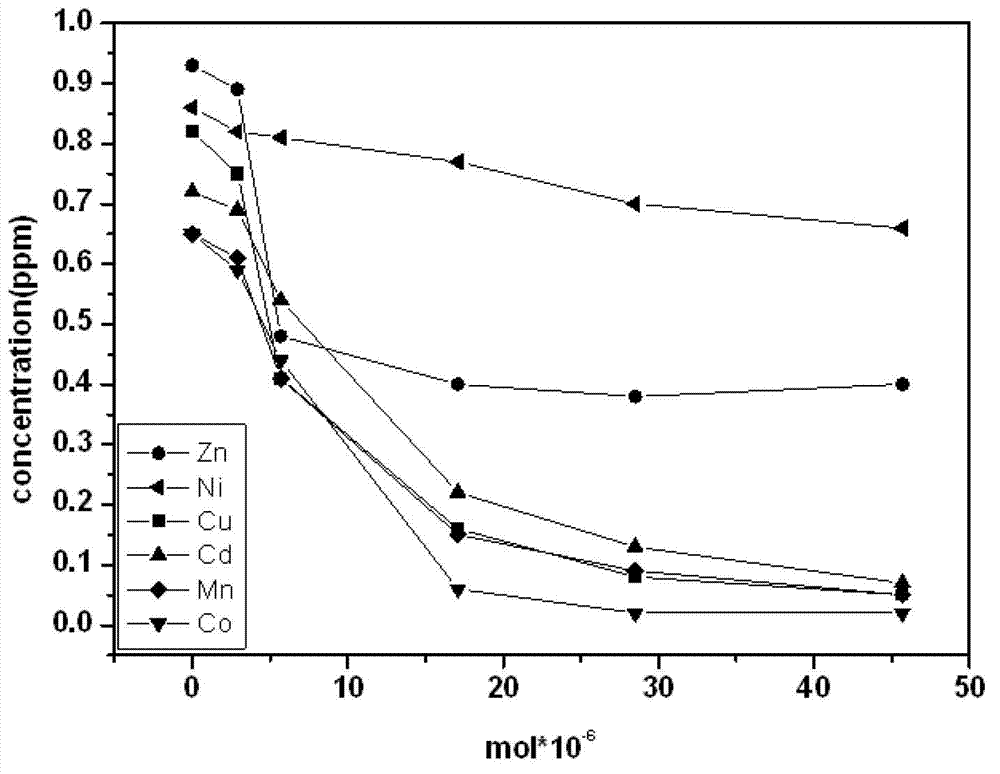

[0047] ① Prepare Ni with a concentration of 1ppm, 10ppm, and 100ppm 2+ solution.

[0048] ②NaA molecular sieve (prepared by Example 11) to Ni 2+ exchange

[0049]

[0050] ICP test test results show that in the final solution, Ni 2+ The concentrations are all less than 0.02ppm.

Embodiment 2

[0052] ① Prepare Mn with concentrations of 1ppm, 10ppm, and 100ppm 2+ solution.

[0053] ②NaA molecular sieve (prepared by Example 11) to Mn 2+ exchange

[0054]

[0055] ICP test results show that when Mn 2+ When the initial concentration is 1ppm and 10ppm, in the final solution, Mn 2+ The concentration is less than 0.02ppm; when Mn 2+ When the initial concentration is 100ppm, in the final solution, Mn 2+ The concentration is 0.09ppm;

[0056] ③NaX type molecular sieve (prepared by embodiment 12) to Mn 2+ exchange

[0057]

[0058] ICP test results show that when Mn 2+ When the initial concentration of 1ppm, 10ppm and 100ppm, in the final solution, Mn 2+ The concentrations are all less than 0.02ppm.

Embodiment 3

[0060] ①Preparation of Co with concentration of 1ppm, 10ppm, 100ppm 2+ solution.

[0061] ②NaA molecular sieve (prepared by Example 11) to Co 2+ exchange

[0062]

[0063] ICP test results show that when Co 2+ When the initial concentration is 1ppm and 10ppm, in the final solution, Co 2+ The concentration is less than 0.02ppm; when Co 2+ When the initial concentration is 100ppm, in the final solution, Co 2+ The concentration is 0.03ppm;

[0064] ③NaX type molecular sieve (prepared by Example 12) to Co 2+ exchange

[0065] In solution, Co 2+ The concentration is less than 0.02ppm; when Co 2+ When the initial concentration is 100ppm, in the final solution, Co 2+ The concentration is 0.03ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com