Outgassing demulsification device of ultrasonic air floatation system

A demulsification device and ultrasonic technology, which are used in oil/oil/float removal devices, flotation water/sewage treatment, mechanical oscillation water/sewage treatment, etc., can solve problems such as no research and achieve controllability The effect of strong, improving efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, the present invention will be further described in detail by taking the embodiment of the accompanying drawings as an example. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

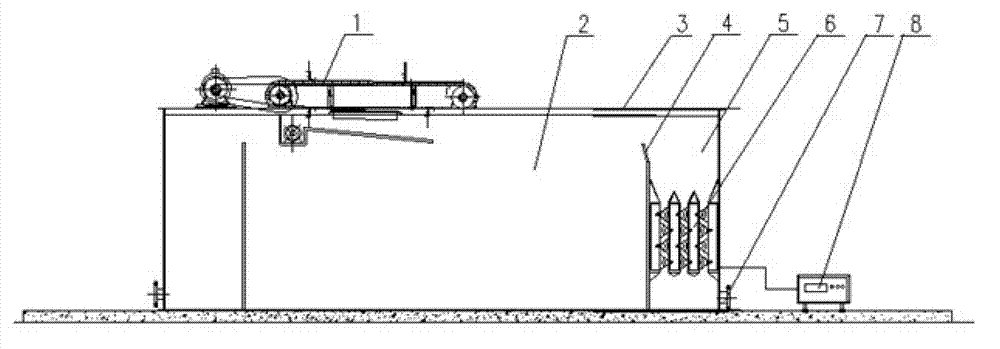

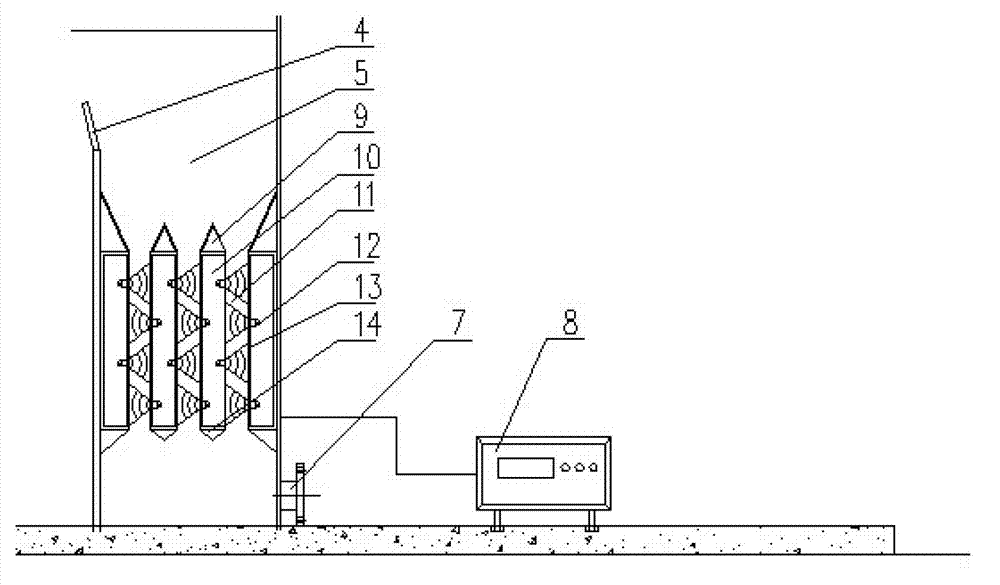

[0022] An ultrasonic air flotation system degassing demulsification device, an ultrasonic reaction zone 5 is set on one side of the air flotation tank 3, a separation zone 2 is set on the other side, an oil scraper 1 is installed above the separation zone, and the ultrasonic reaction zone and the separation zone are installed The inclined partitions 4 inclined outwards are fixed vertically between them to stabilize the water flow; the water inlet 7 is installed on the air flotation tank at the bottom of the ultrasonic reaction zone, and the degassing and demulsification device 6 is installed in the ultrasonic reaction zone. The device is connected to the ultrasonic generator 8 installed outside the air fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com