Poly (N- isopropyl acrylamide)- poly (crylic acid or acrylic acid derivative) copolymer and preparation method thereof

A technology of isopropylacrylamide and acrylic acid, applied in the polymer field, can solve the problems of complex synthesis method and long synthesis route, and achieve the effects of broad application prospects, complete phase transformation and widening application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention also provides a preparation method of poly(N-isopropylacrylamide)-poly(acrylic acid or acrylic acid derivative) copolymer, comprising the following steps:

[0042] Under the action of azobisisobutyronitrile, react N-isopropylacrylamide with the compound represented by formula (III) in an organic solvent at 60°C~90°C to obtain poly(N-isopropylacrylamide amide)-poly(acrylic acid or acrylic acid derivative) copolymer;

[0043]

[0044] Among them, R 1 is hydrogen or C1~C5 alkyl; R 2 It is hydrogen or C1~C5 alkyl.

[0045] The present invention reacts N-isopropylacrylamide and the compound represented by formula (III) under the action of azobisisobutyronitrile in an organic solvent at 60°C to 90°C to obtain poly(N-isopropylacrylamide) acrylamide)-poly(acrylic acid or acrylic acid derivative) copolymer.

[0046] The present invention uses N-isopropylacrylamide and the compound represented by formula (III) as raw materials to react, and the random...

Embodiment 1

[0057] Dissolve 0.9g of N-isopropylacrylamide, 0.1g of 2-butenoic acid and 0.0164g of azobisisobutyronitrile in 10mL of dimethyl sulfoxide. After dissolution, the solution is heated to 70°C for reaction, and the temperature is maintained for 24 hours to obtain crude product;

[0058] The obtained crude product was placed in a dialysis bag with a molecular weight cut-off of 7000, dialyzed in water for 72 hours, and changed the water once every 12 hours to obtain the dialysis product;

[0059] The resulting dialysis product was frozen and then freeze-dried to obtain poly(N-isopropylacrylamide)-poly(2-butenoic acid) copolymer (PNM), with an average molecular weight of 10,000.

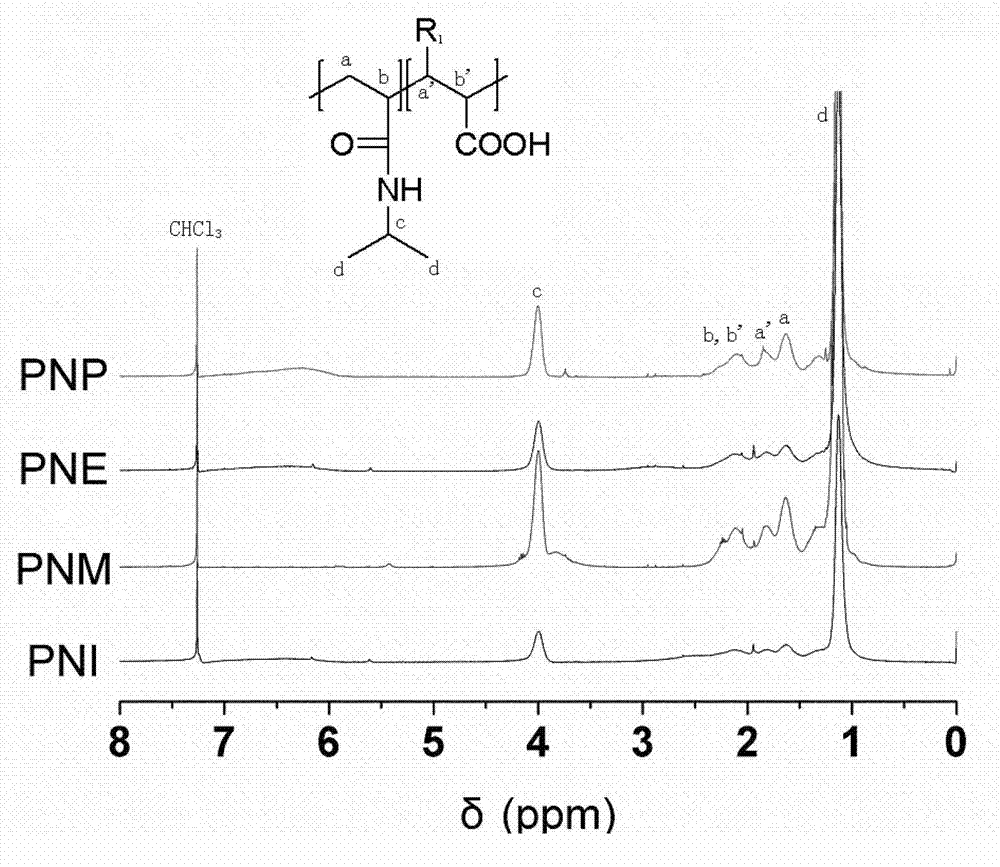

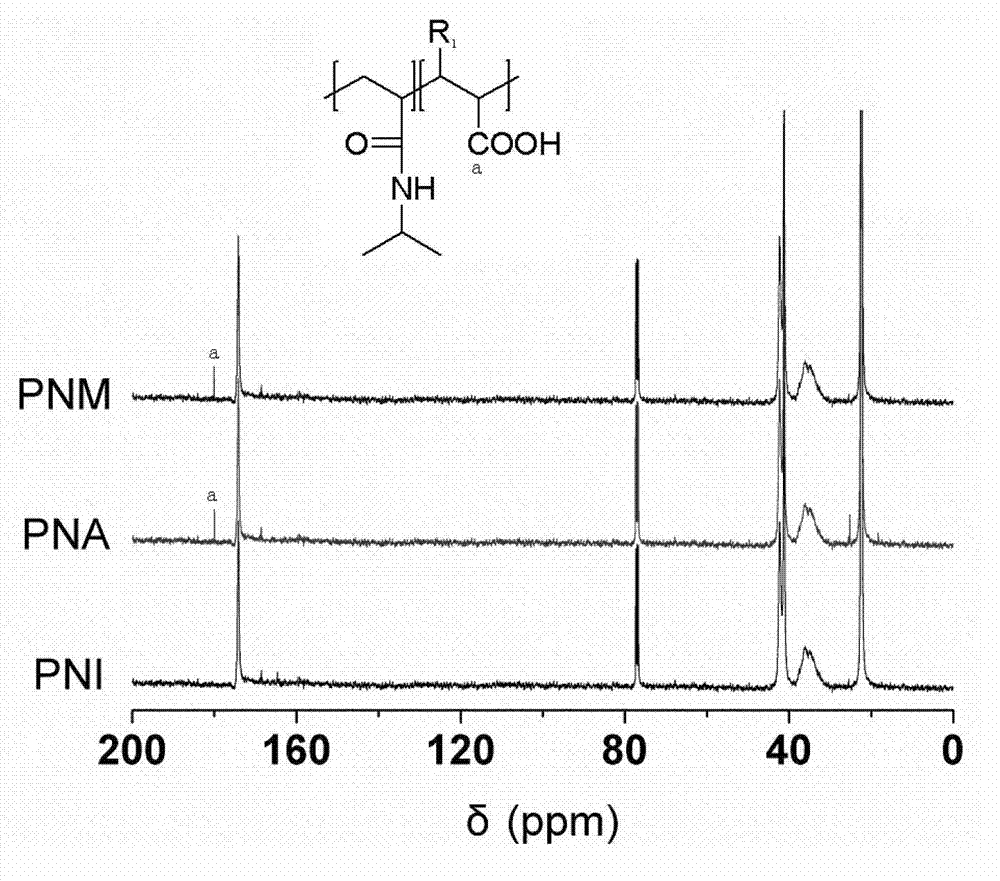

[0060] The resulting copolymer was subjected to nuclear magnetic resonance analysis, using deuterated chloroform as a solvent. Analysis results such as figure 1 with figure 2 as shown, figure 1 The H NMR spectra of the copolymers and poly(N-isopropylacrylamide) homopolymers provided in Examples 1, 3, ...

Embodiment 2

[0063] Dissolve 0.9g of N-isopropylacrylamide, 0.1g of acrylic acid and 0.0164g of azobisisobutyronitrile in 10mL of dimethyl sulfoxide. After dissolution, the solution is heated to 70°C for reaction, and the temperature is maintained for 24 hours to obtain a crude product;

[0064] The obtained crude product was placed in a dialysis bag with a molecular weight cut-off of 7000, dialyzed in water for 72 hours, and changed the water once every 12 hours to obtain the dialysis product;

[0065] The resulting dialysis product was frozen and then freeze-dried to obtain poly(N-isopropylacrylamide)-polyacrylic acid copolymer (PNA), with an average molecular weight of 10,000.

[0066] Gained copolymer is carried out nuclear magnetic resonance analysis, with deuterated chloroform as solvent, analysis result is as follows figure 2 shown. The analysis results showed that the obtained copolymer PNA includes the first repeating unit having the structure of formula (I) and the second repea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com