A Microetching Process Method for Suppressing Microdischarge Effect of Microwave Components

A technology of micro-discharge effect and microwave components, which is applied in the field of surface treatment of microwave components, can solve the problems of inability to suppress secondary electron emission, aluminum alloy materials are not resistant to high temperature, and the depth of traps is limited, so as to avoid heavy metal pollution and maintain continuous properties, the effect of suppressing secondary electron emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

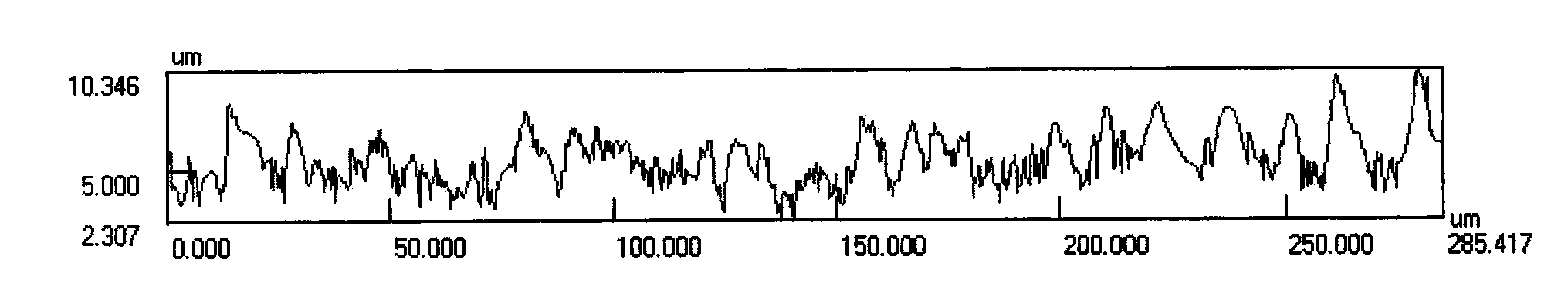

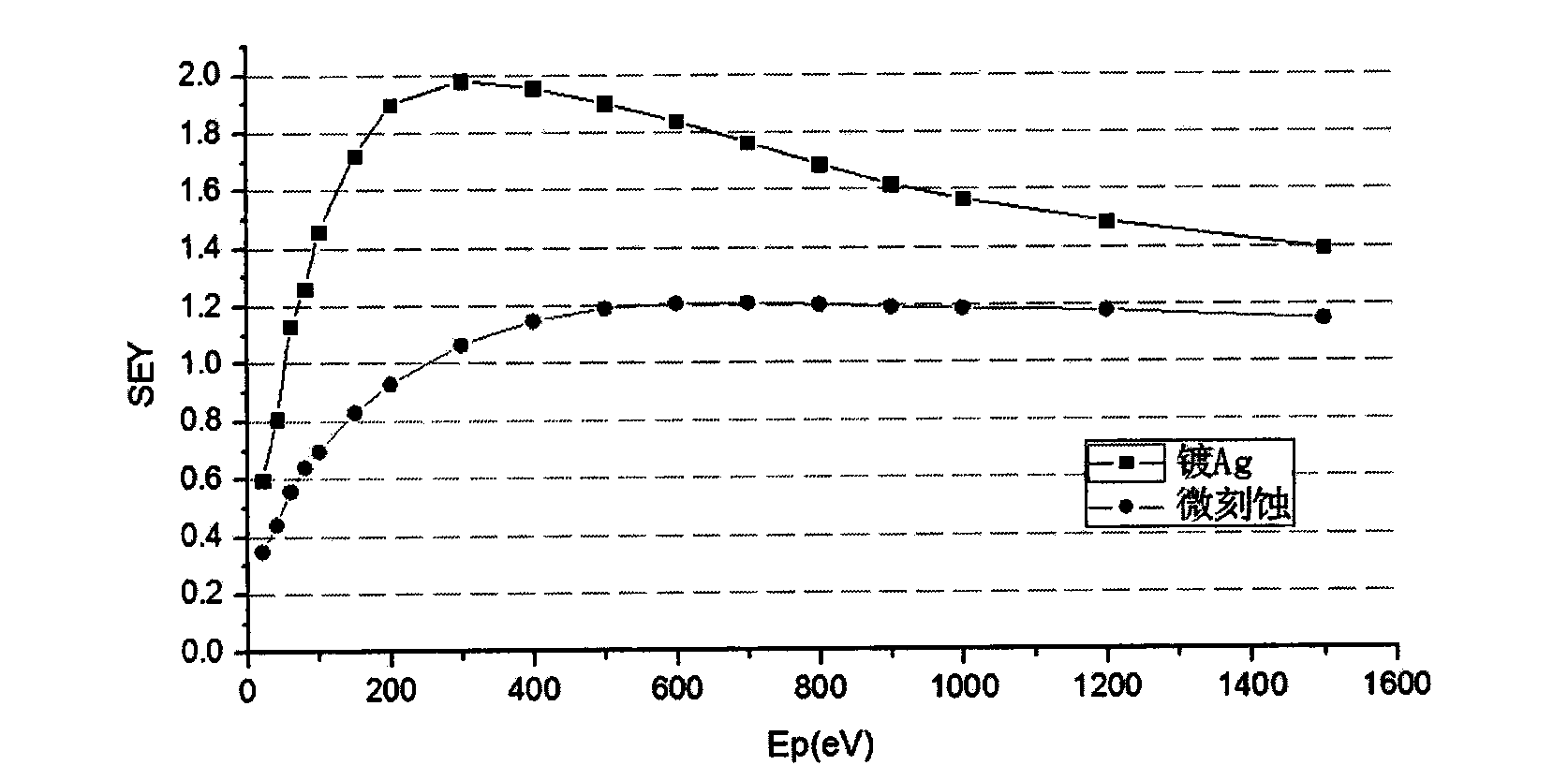

[0029] In the present invention, the microwave component adopts aluminum alloy silver-plated material. The principle of the present invention is to micro-etch the aluminum alloy silver-plated surface by chemical method, so that the smooth silver-plated surface of the microwave component forms a nano-micro-trap structure, so as to suppress secondary electron emission. Purpose. The Ku-band impedance converter is a commonly used space microwave component. The micro-discharge suppression method proposed by the present invention will be described below by taking the Ku-band impedance converter as an example.

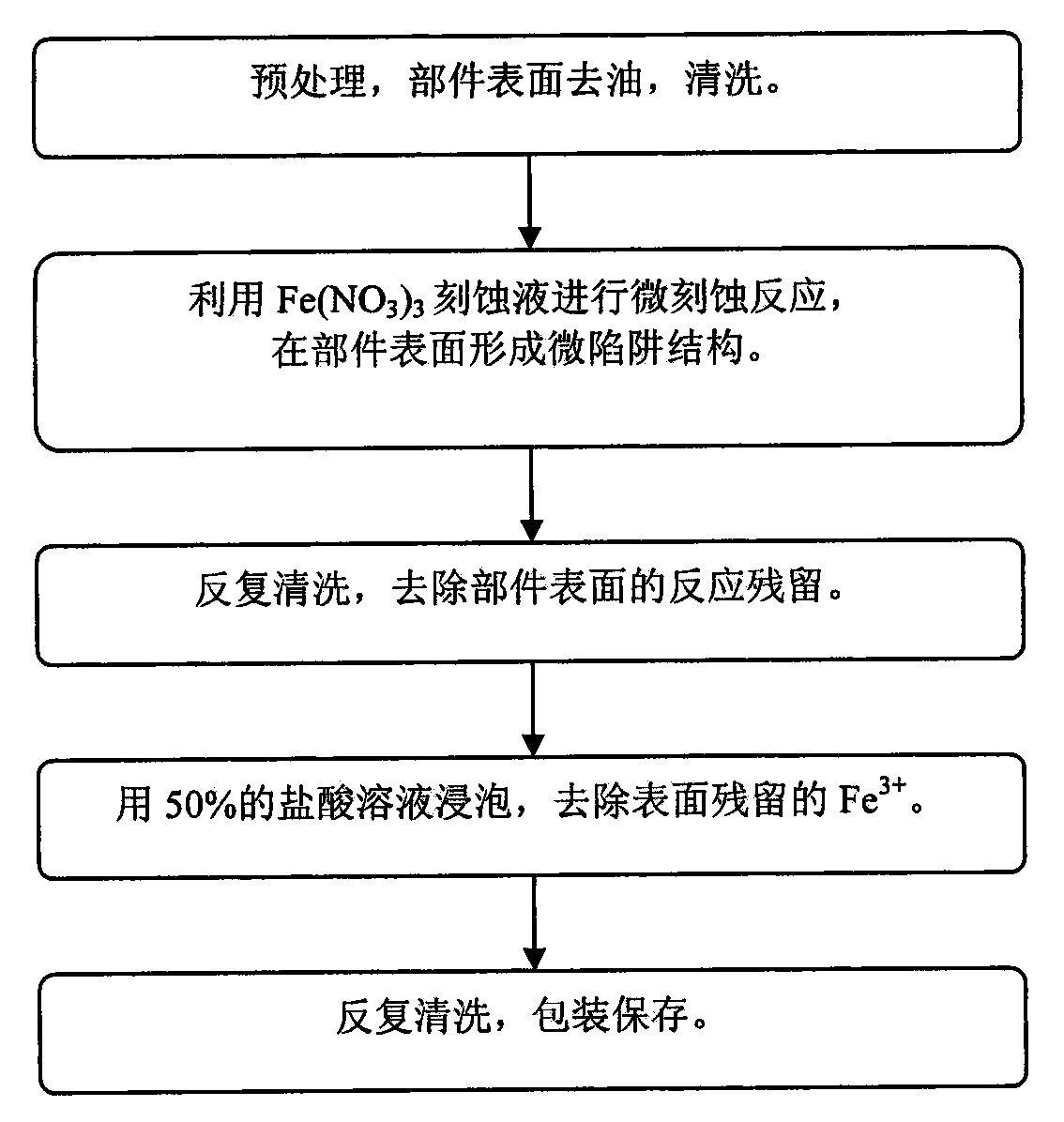

[0030] Such as image 3 Shown, the concrete steps of the inventive method are as follows:

[0031] A micro-etching process method for suppressing the micro-discharge effect of microwave components, characterized in that the steps are as follows:

[0032] (1) Degreasing and cleaning the surface of the microwave components;

[0033] Specifically: firstly use acetone and etha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com