Sludge discharge field constructing method for speeding up dehydration, solidification and stabilization of dredged sediment

A technology for dredging sediment and a construction method, applied in the field of environmental engineering, can solve the problems of high production cost and reduced feasibility, and achieve the effects of increasing the contact surface, increasing the drainage rate, and increasing the area of the effective working area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

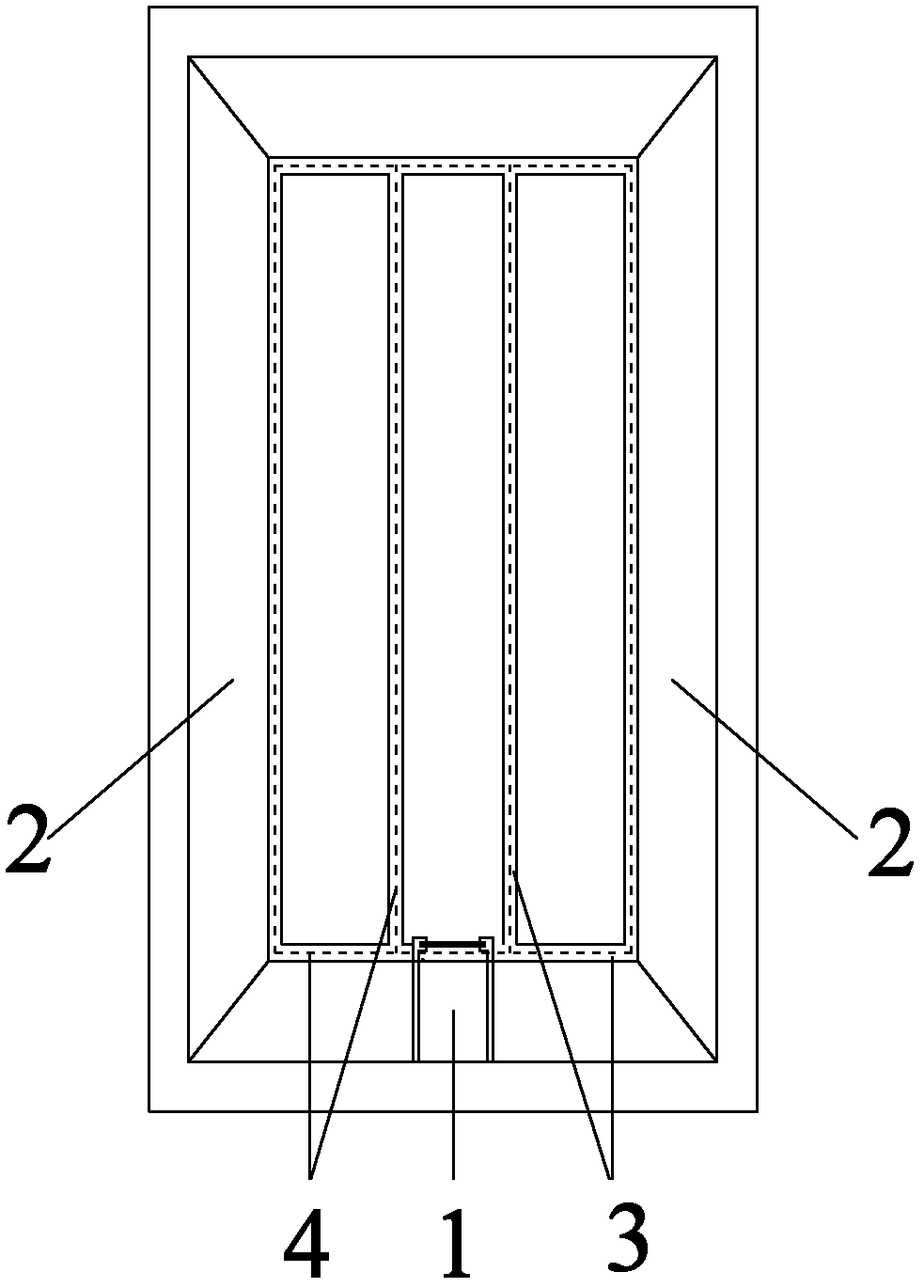

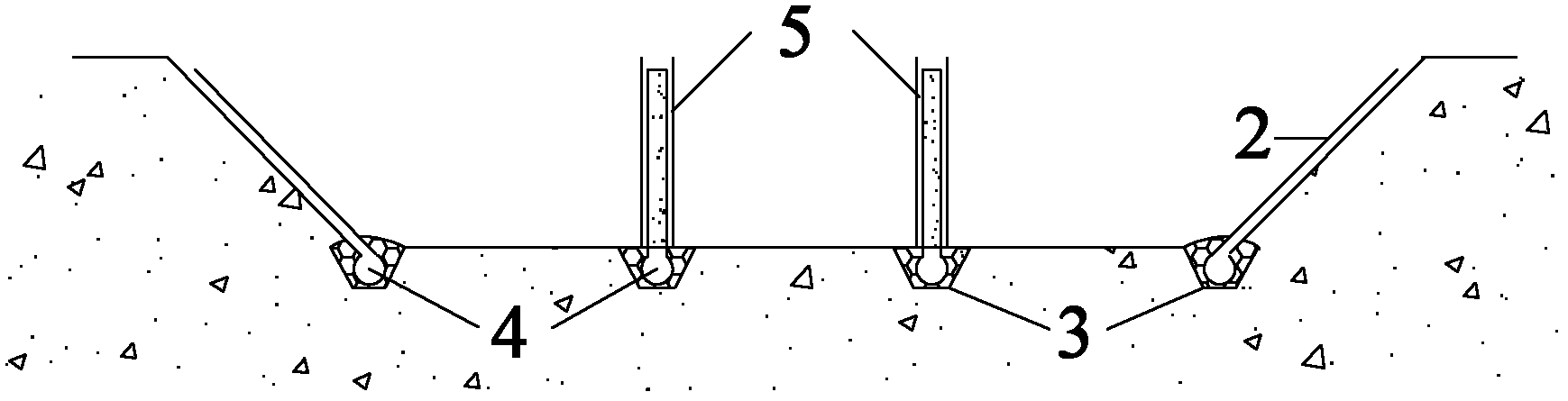

[0023] Implement the mud discharge field that the present invention builds, as figure 1 and figure 2 shown. According to the technical scheme of the present invention, it includes: the side slope strengthening drainage layer 2 on the inner slope of the weir around the mud discharge field, the vertical drainage wall 5 arranged in the field, the drainage ditch 3 at the bottom of the side slope and the bottom of the drainage wall, and the drainage ditch The drainage pipe 4 in the middle, and the retreat pool 1 is set below the mud discharge field.

[0024] The specific steps of carrying out the construction of the mud discharge field according to the present invention are as follows: first, according to the design size of the mud discharge field, adopt the mode of layer by layer tamping to carry out the construction of the surrounding weirs around the mud discharge field, and build a retreat on one side of the mud discharge field. Ponds and outlets; construction of a side slop...

Embodiment 2

[0031]A construction method for accelerating the dehydration and solidification of dredged sediment and stabilizing a mud discharge field. The method lays a reinforced drainage layer on the inner slope of the cofferdam around the mud discharge field. A drainage collection pipe is arranged at the bottom of the reinforced drainage layer. The reinforced drainage layer includes laying in sequence The anti-seepage layer, diversion drainage layer and water seepage layer, the drainage collection pipe is placed in the drainage ditch, and gravel is filled around it to form a side slope drainage system. At the same time, a vertical drainage wall drainage system is set in the middle of the mud discharge field. Wooden fixed piles, the vertical drainage wall is composed of supporting skeleton iron mesh, filler seepage bricks and outsourcing seepage geotextile, the drainage collection pipe is set under the drainage wall, the diameter of the pipe is 100mm, and a seepage hole with a diameter of...

Embodiment 3

[0033] A construction method for accelerating the dehydration and solidification of dredged sediment and stabilizing a mud discharge field. The method lays a reinforced drainage layer on the inner slope of the cofferdam around the mud discharge field. A drainage collection pipe is arranged at the bottom of the reinforced drainage layer. The reinforced drainage layer includes laying in sequence The anti-seepage layer, diversion drainage layer and water seepage layer, the drainage collection pipe is placed in the drainage ditch, and gravel is filled around it to form a side slope drainage system. At the same time, a vertical drainage wall drainage system is set in the middle of the mud discharge field. Bamboo fixed piles, the vertical drainage wall is made of bamboo braids as the supporting frame, gravel as the filler, and is covered with water-seeping non-woven fabrics. The drainage collection pipe is installed under the drainage wall. The diameter of the pipe is 250mm, and the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com