Adduction disc type pipeline angle valve capable of being adjusted to be opened and closed

A technology for adjusting switches and pipelines, which is applied in the direction of lifting valves, valve details, valve devices, etc., can solve the problems that plague the design institute and end customers, and the sealing problem of large-diameter plunger angle valves, etc., so as to reduce the dead zone of the medium and facilitate on-line The effect of maintaining and improving the safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific drawings and embodiments.

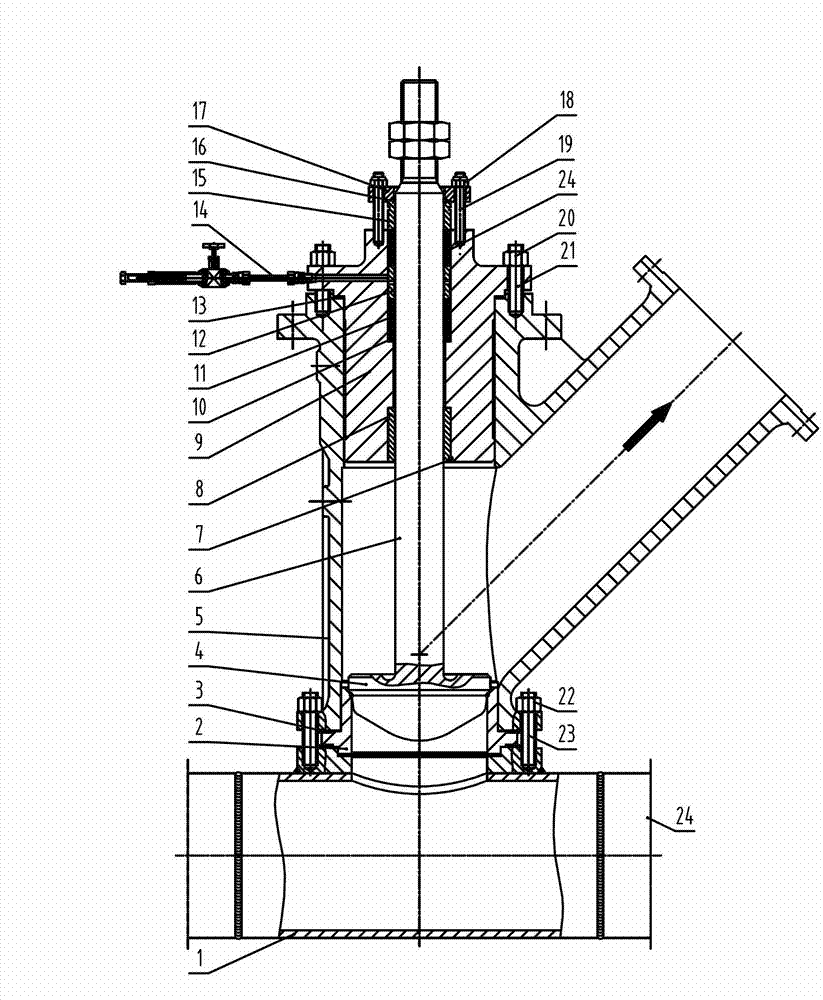

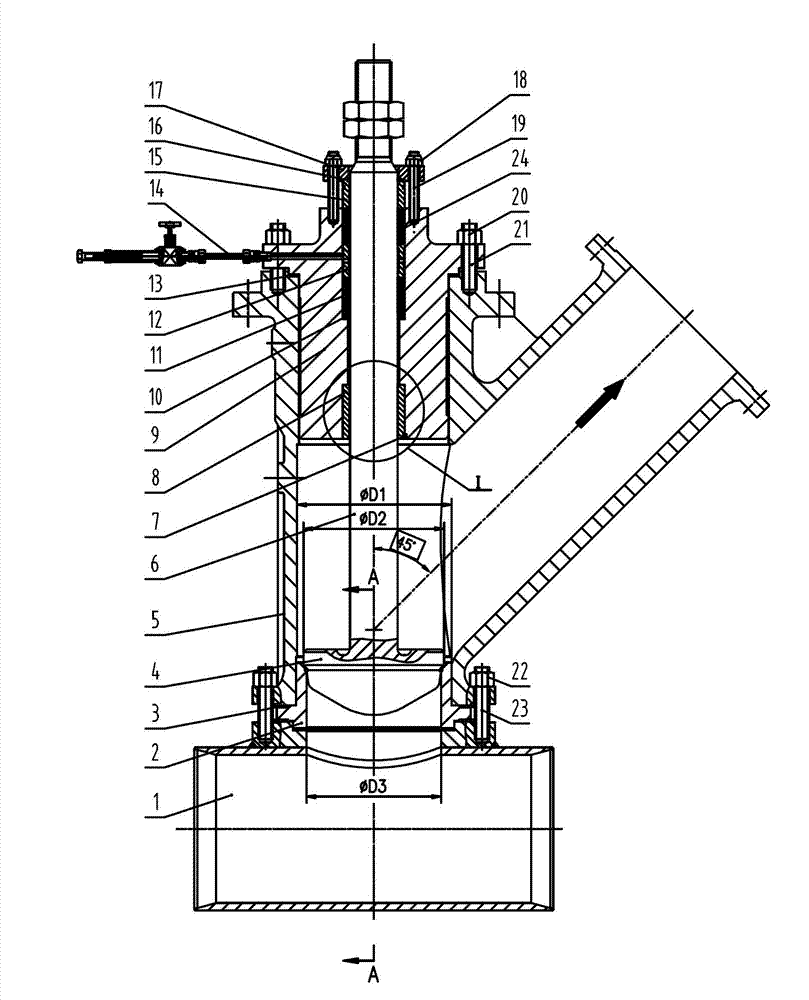

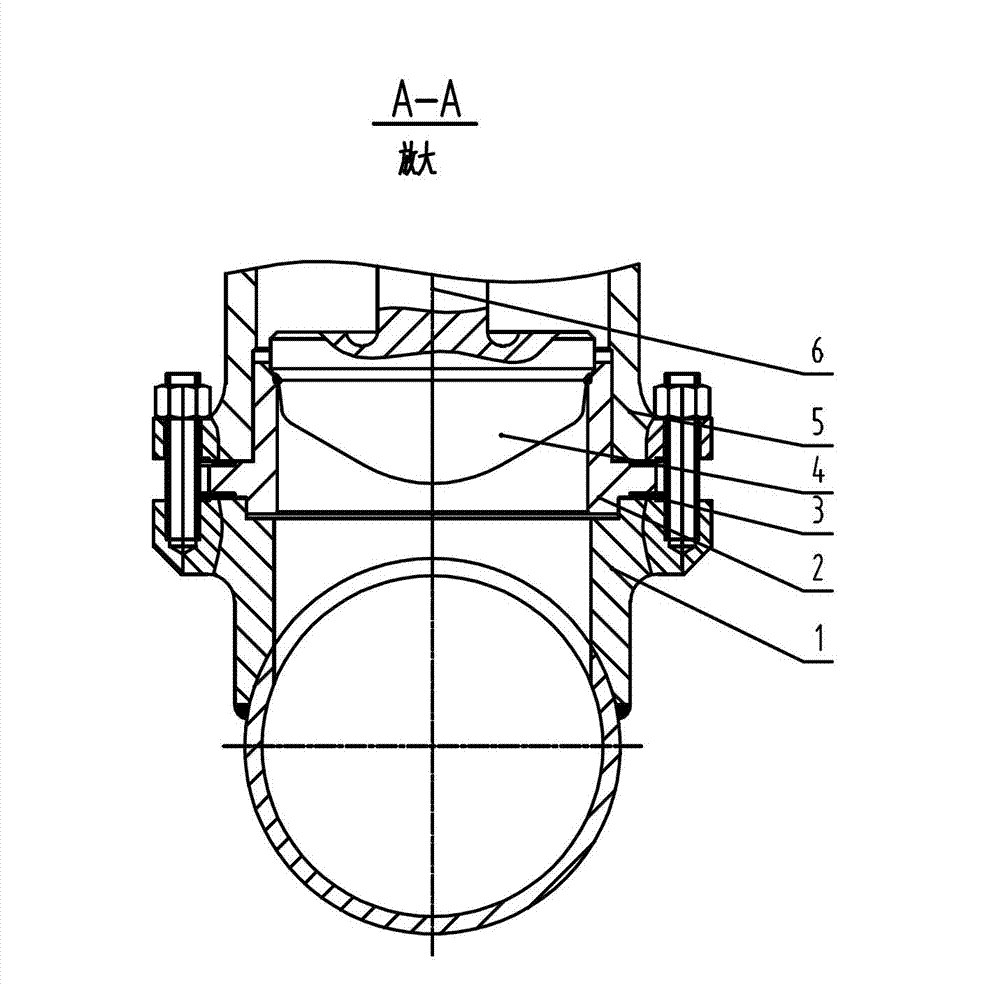

[0026] like figure 1 Shown: an inner expansion disc-type regulating switch pipeline angle valve, including a T-shaped pipe 1 and an angle-shaped valve body 5, the T-shaped pipe 1 is usually butt-welded with the customer's on-site process pipeline 25, and the angle-shaped valve body 5 can be used as required Install at any angle.

[0027] like Figure 2 ~ Figure 6 Shown: the present invention comprises T-shaped pipe 1, valve seat 2, gasket 3, valve core 4, angle valve body 5, valve stem 6, set screw 7, guide sleeve 8, upper cover 9, packing pad 10, First packing assembly 11, packing spacer 12, sealing ring 13, oiler 14, packing gland 15, dustproof ring 16, packing pressure plate 17, pressure plate nut 18, pressure plate stud 19, upper cover nut 20, upper cover screw Column 21, valve body nut 22, valve body stud 23, second packing assembly 24, etc.

[0028] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com