Round barrel type solar hot water warmer

A technology for solar hot water and heaters, applied in solar thermal power generation, solar thermal devices, heating devices, etc., can solve the problems of fast heat conduction, unrecoverable heat, and low surface temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

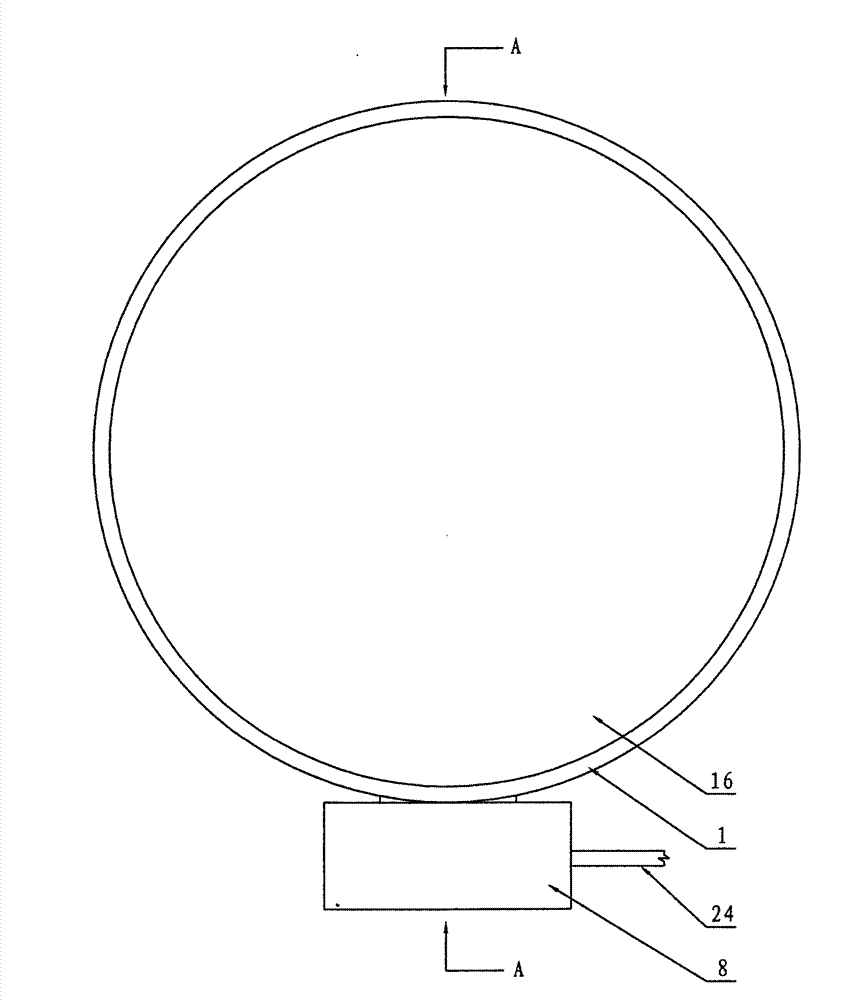

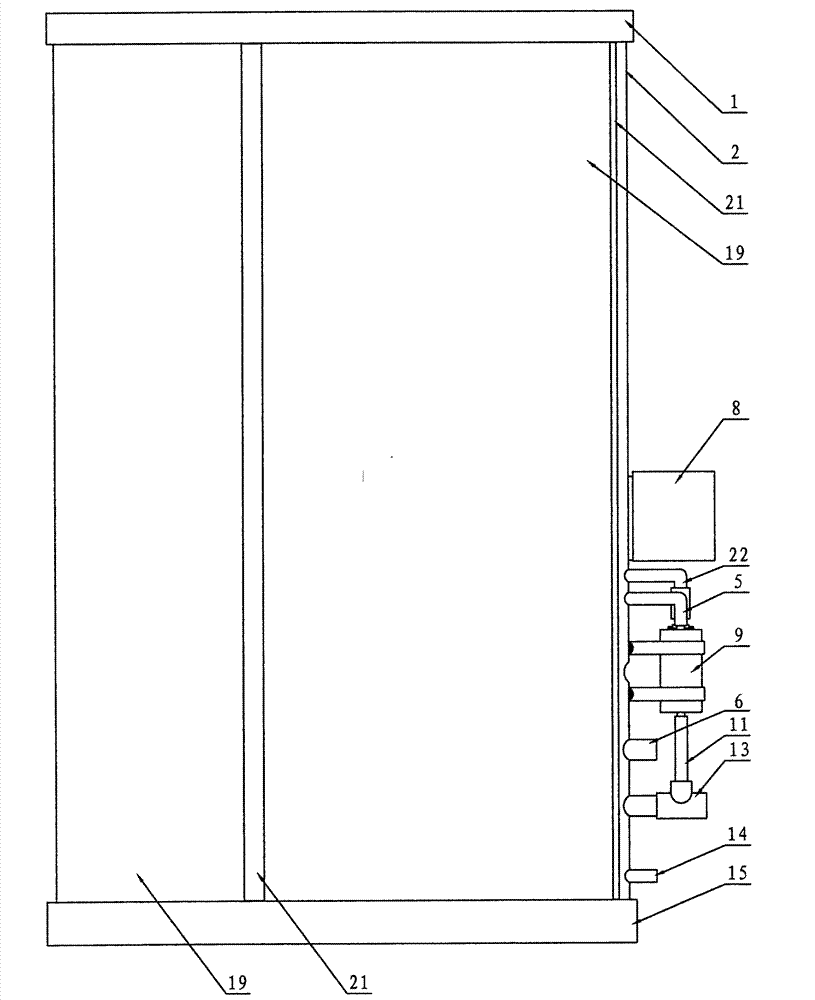

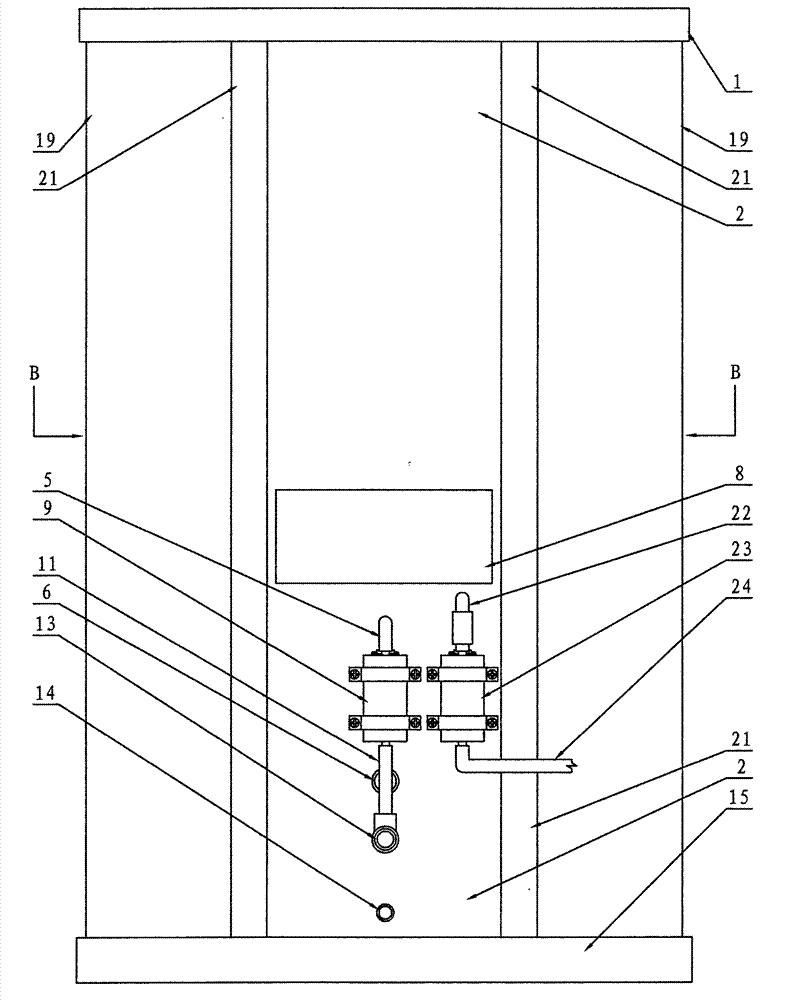

[0026] see Figure 1 to Figure 8, adopt the bottom connecting seat 15 that is placed flat on the ground or the roof or placed on the sloped roof through the inclined bracket to open the bottom round pipe mouth of the lower end round pipe, and install the upper and lower round pipes on the bottom connecting seat 15. The internal water storage tank 7 of stainless steel material with closed pipe mouth, the upper end round pipe mouth closed and the lower end round pipe mouth open lower end port are installed on the periphery and top surface of this hot water storage tank 7. The bottom surface of the bottom connecting seat 15 is fixedly connected to the hot water storage tank 7 through a heat-insulating round tube, and the gap between the inner surface of the heat-insulating material and the mirror surface stainless steel material of the barrel-shaped water storage tank 4 is filled. Around and on the top surface of the water tank 4, the top of the round pipe at the upper end is ins...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap