Ultra-short base line differential plate type optical fiber displacement sensor and optical fiber strain gauge

A displacement sensor and ultra-short baseline technology, applied in the field of strain gauges, can solve the problems of electromagnetic interference, output nonlinearity, and unsuitable strain gauges for long-term stable and reliable operation of the sensor, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the embodiments and drawings, but the protection scope of the present invention should not be limited by this.

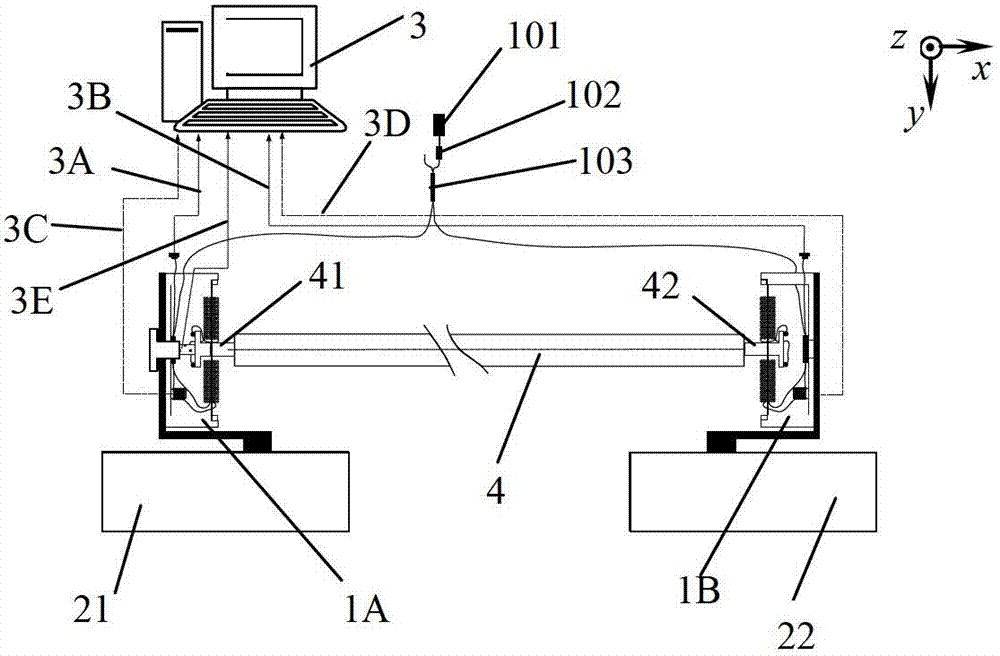

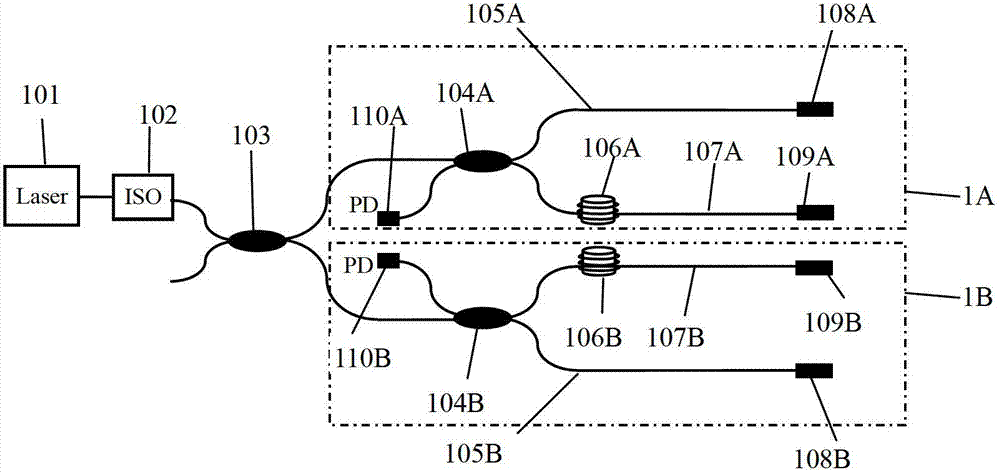

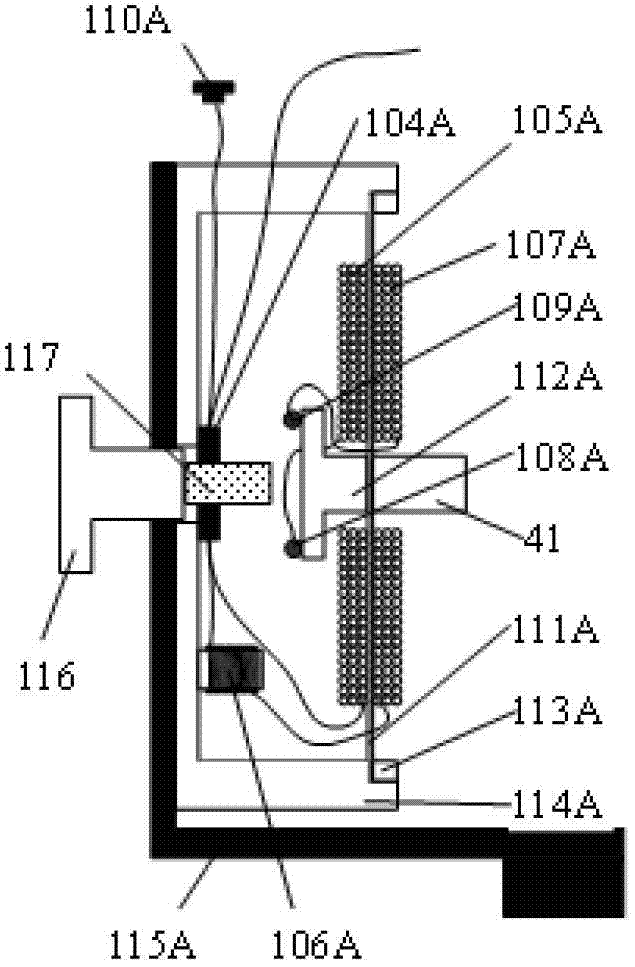

[0048] Combine figure 1 The optical fiber strain gauge of the present invention is composed of displacement sensors 1A, 1B, measurement baseline rod 4, measurement bedrock 21, 22, and measurement control and signal recording and processing system 3. The first optical fiber displacement is fixed on the first bedrock 21 The sensor 1A is connected to one end 41 of the measurement baseline 4; the second optical fiber displacement sensor 1B fixed on the second bedrock 22 is connected to the other end 42 of the measurement baseline 4; the locking knob 116 and the piezoelectric ceramic displacement generator constitute a displacement calibration device , And connected with the first optical fiber displacement sensor 1A; the first optical fiber displacement sensor 1A and the second optical fiber di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com