Neodymium iron boron metallographic analysis sample preparation method

A metallographic analysis and NdFeB technology, which is applied in the field of NdFeB metallographic analysis sample preparation, can solve problems such as blurred metallographic patterns and difficulties in metallographic sample preparation, and achieve clear grain boundaries, obvious microstructure defects, and The simple effect of the sample process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Such as figure 1 Shown: a sample preparation method for NdFeB metallographic analysis. The method is to grind the NdFeB magnet sample flat on a grinding machine, and then polish it with a polishing machine equipped with 1000-mesh metallographic sandpaper. During the polishing process, add Water is used as a lubricant. After polishing, use a mixture of alcohol with a mass fraction of 88% and nitric acid with a mass fraction of 12% as a corrosion solution. Use a cotton swab dipped in a small amount of corrosion solution, and repeatedly wipe the polished surface 20 times in one direction, and then rinse with water. Clean it and put it on the metallographic analyzer for analysis.

Embodiment 2

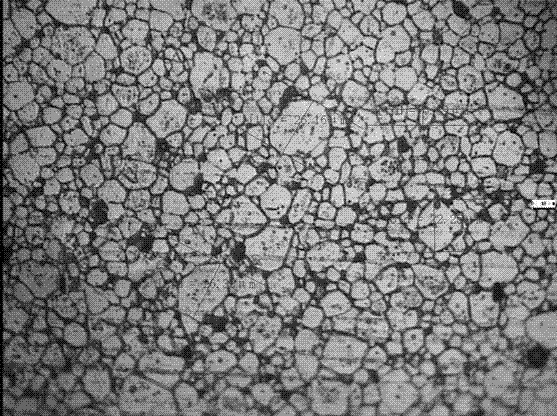

[0012] Such as figure 2 Shown: a sample preparation method for NdFeB metallographic analysis. The method is to grind the NdFeB magnet sample flat on a grinding machine, and then polish it with a polishing machine equipped with 1000-mesh metallographic sandpaper. During the polishing process, add Water is used as a lubricant. After polishing, use a mixture of alcohol with a mass fraction of 92% and nitric acid with a mass fraction of 8% as a corrosion solution. Use a cotton swab dipped in a small amount of corrosion solution, and repeatedly wipe the polished surface 25 times in one direction, and then rinse with water. Clean it and put it on the metallographic analyzer for analysis.

Embodiment 3

[0014] Such as image 3 Shown: a sample preparation method for NdFeB metallographic analysis. The method is to grind the NdFeB magnet sample flat on a grinding machine, and then polish it with a polishing machine equipped with 1000-mesh metallographic sandpaper. During the polishing process, add Water is used as a lubricant. After polishing, use a mixture of alcohol with a mass fraction of 90% and nitric acid with a mass fraction of 10% as a corrosion solution. Use a cotton swab dipped in a small amount of corrosion solution, and repeatedly wipe the polished surface in one direction for 30 times, and then rinse with water. Clean it and put it on the metallographic analyzer for analysis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com