A kind of preparation method of metallographic sample of titanium alloy pendulum milling piece

A technology for metallographic samples and titanium alloys, which is applied to instruments, measuring devices, scientific instruments, etc., can solve the problems of inability to corrode grain boundaries, complicated sample preparation procedures, and long sample preparation cycles, so as to facilitate observation and observation. Accurate and short sample preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

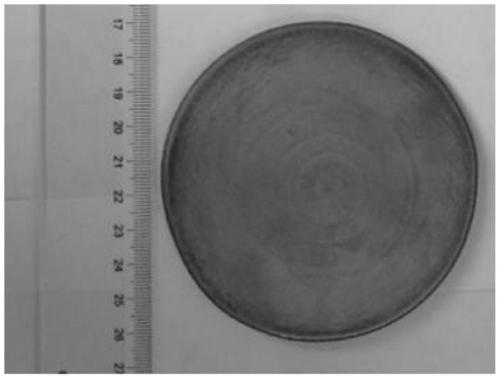

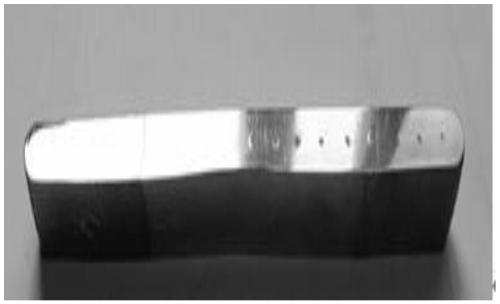

[0026] Take the TC4 titanium alloy 800 ℃ rotary rolling sample and place it on a wire cutting machine to cut it into a long sample with a width of 10~20mm, a thickness of 5~10mm, and a length of 20~70mm; first chamfer the sample, and then The sample is roughly ground, and the scratches are in the shape of a cross, which can effectively eliminate the previous scratches, and then the samples are ground with 280#, 400#, 600#, 800# silicon carbide dry and wet sandpaper It is made by cross-grinding by dry grinding method, and the previous ink mark must be completely covered during each grinding process; then use Wuxi brand green silicon carbide dry-wet sandpaper to fine-tune Grinding, cross-grinding by wet grinding method, the grinding process should ensure that the surface of the sample is uniform and smooth until it is bright, and then use flannelette polishing cloth and aluminum oxide nano-scale polishing powder, and the number of revolutions of the polishing machine is adjusted ...

Embodiment 2

[0029] Take the TC4 titanium alloy 900 ℃ rotary rolling sample and place it on a wire cutting machine to cut it into a long sample with a width of 10~20mm, a thickness of 5~10mm, and a length of 20~70mm; first chamfer the sample, and then The sample is roughly ground, and the scratches are in the shape of a cross, which can effectively eliminate the previous scratches, and then the samples are ground with 280#, 400#, 600#, 800# silicon carbide dry and wet sandpaper It is made by cross-grinding by dry grinding method, and the previous ink mark must be completely covered during each grinding process; then use Wuxi brand green silicon carbide dry-wet sandpaper to fine-tune Grinding, cross-grinding by wet grinding method, the grinding process should ensure that the surface of the sample is uniform and smooth until it is bright, and then use flannelette polishing cloth and alumina nano-scale polishing powder, and the number of polishing machine revolutions is adjusted at 800 rpm. M...

Embodiment 3

[0032] Take the TC4 titanium alloy 1000 ℃ rotary rolling sample and place it on a wire cutting machine to cut it into a long sample with a width of 10~20mm, a thickness of 5~10mm, and a length of 20~70mm; first chamfer the sample, and then The sample is roughly ground, and the scratches are in the shape of a cross, which can effectively eliminate the previous scratches, and then the samples are ground with 280#, 400#, 600#, 800# silicon carbide dry and wet sandpaper It is made by cross-grinding by dry grinding method, and the previous ink mark must be completely covered during each grinding process; then use Wuxi brand green silicon carbide dry-wet sandpaper to fine-tune Grinding, cross-grinding by wet grinding method, the grinding process should ensure that the surface of the sample is uniform and smooth until it is bright, and then use flannelette polishing cloth and aluminum oxide nano-scale polishing powder, and the number of polishing machine revolutions is adjusted at 900...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com