Transmission electron microscope sample preparation method suitable for dissimilar material welding joint interface analysis

A technology of dissimilar materials and welded joints, which is applied in the direction of material analysis using radiation, material analysis using wave/particle radiation, and material analysis. The effect of low cost and short time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Using ion thinning technology to carry out transmission electron microscope sample preparation on welded joints of aluminum and steel dissimilar materials, the specific steps are as follows:

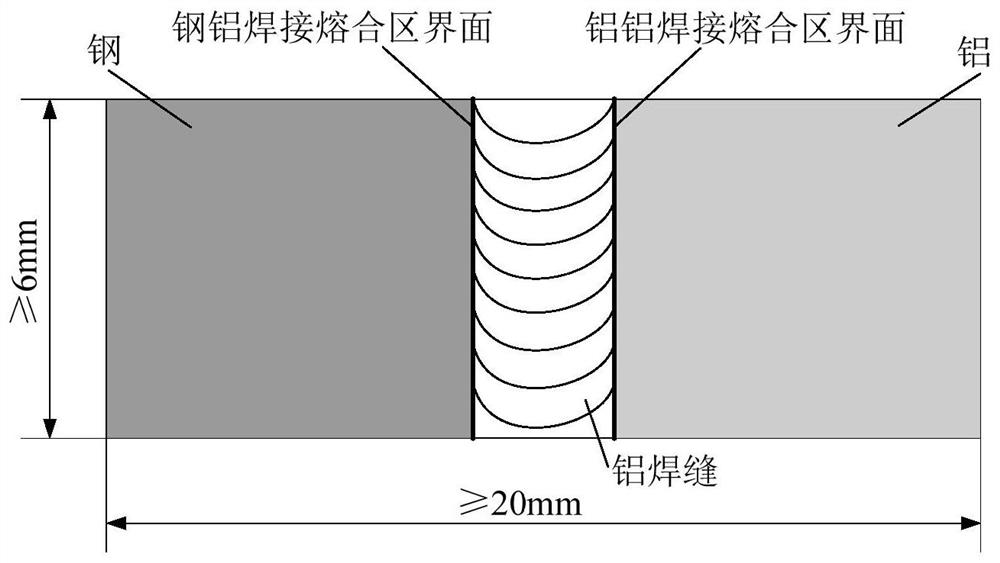

[0043] (a), if figure 1 , the form of the welded joint of dissimilar materials is a lap joint, and the sample of the welded joint of dissimilar materials is prepared by wire cutting into a plane size greater than or equal to 20mm╳6mm, and the initial sample is a uniform thin sheet with a thickness of about 1.0mm, so that the base metal of aluminum and steel accounts for each Half the area, and symmetrical to the weld, such as figure 2 , 3 .

[0044] (b) Put the initial wire-cut sample into an acetone solution, and clean it with ultrasonic vibration to remove surface oil.

[0045] (c) Stick the sample on a metal or glass substrate of appropriate size, and perform manual flat grinding on sandpaper. When grinding, use force on the steel side and light force on the aluminum side,...

Embodiment 2

[0057] The transmission electron microscope sample preparation method for the interface analysis of welded joints of dissimilar materials, the specific steps refer to Example 1, the differences are as follows:

[0058] In step (c), the sample is ground into a uniform sheet with a thickness of about 50 μm.

[0059] In step (f), the speed of the grinding wheel is in 3rd gear, and the sample rotation speed is in 3rd gear.

[0060] In step (g), the grinding pressure is set to 20g during the pit.

[0061] In step (i), the sample is first ground to a range of 20 μm using a fine grinding paste with 3-6 μm particles. At this thickness, replace the abrasive paste of 0.5 μm for continuous polishing, so that the remaining thickness of the sample is 10 μm.

[0062] In step (j), the ion gun angle is set to 8°, the acceleration energy is set to 5keV, the sample rotation speed is 3rpm, and the current readings of the left and right ion guns need to be greater than 6μA.

[0063] In step (l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com