Automatic measurement device and method for brix and purity of sugar liquor

A technology for automatic measurement of the brix of sugar liquid, which is applied in the direction of measuring devices, preparation of test samples, and polarization-influenced characteristics. The effect of improving quality, convenient operation, and shortening the detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, the present invention will be further described:

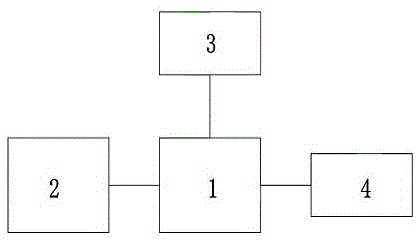

[0030] figure 1 As shown, it is a schematic diagram of the control structure of the present invention. The automatic measuring device for the brix and purity of the sugar liquid of the present invention is mainly composed of a PLC 1, a touch screen 2, a sample dilution device 3 and a detector 4 comprising a brix detector and an optical rotation detector. , PLC1 is electrically connected with the touch screen 2, the sample dilution device 3 and the detector 4 through relevant connection lines. The operator sends instructions to PLC1 through the touch screen 2, and PLC1 can automatically control the operation of the sample dilution device 3 and the detector 4, and receive the detection data information fed back by the sample dilution device 3, Brix and purity detector 4, and process the data , and display the processing or calculation results on the touch screen 2 .

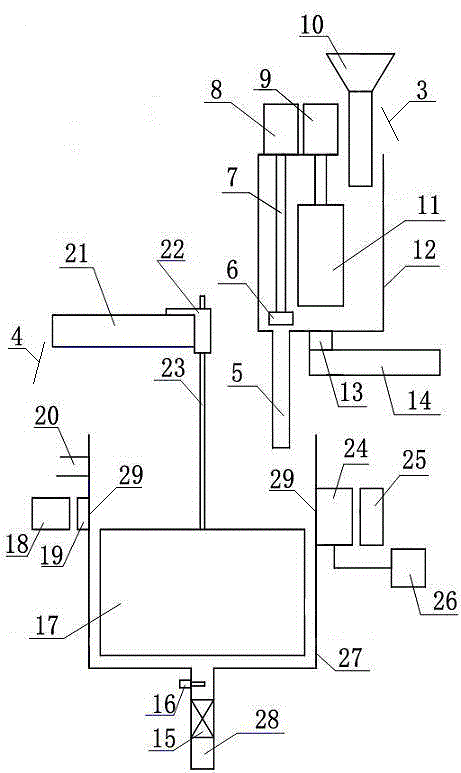

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com