Method for preparing ethylene diamine tetraacetic acid (EDTA) modified carbon paste carbon nano tube membrane electrode

A carbon nanotube film and carbon paste electrode technology is applied in the field of preparation of carbon nanotube film electrodes, and can solve the problems of unstable electrode tube decoration layer and difficult control of copper wire propulsion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

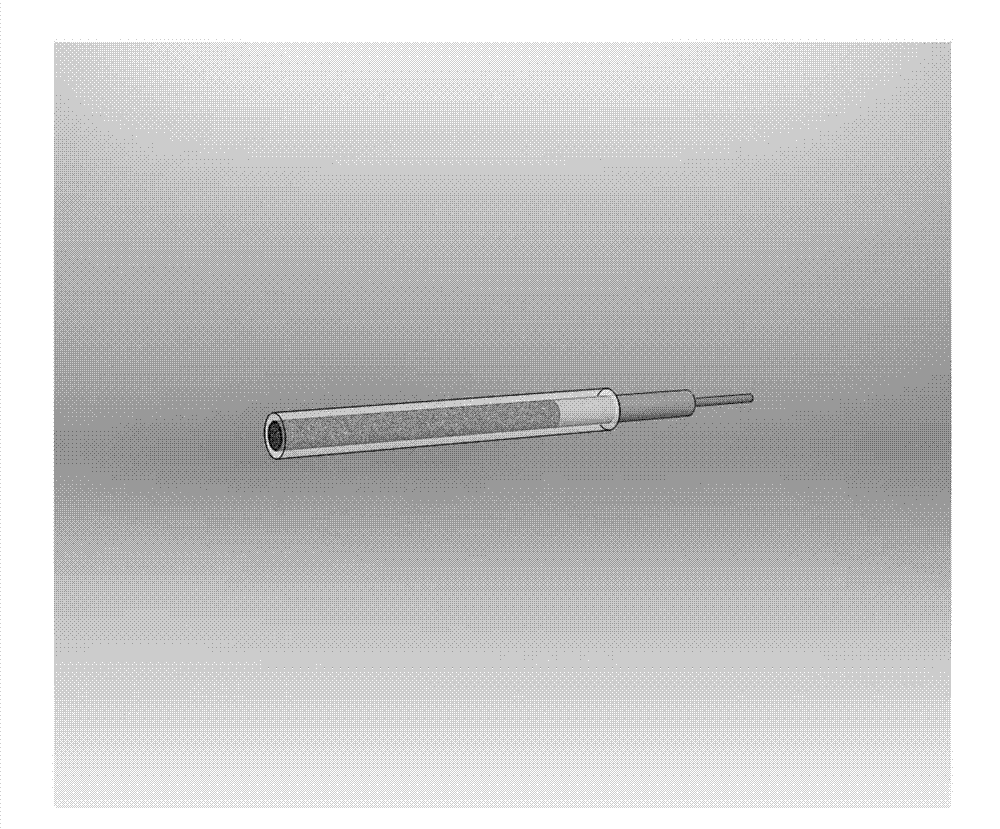

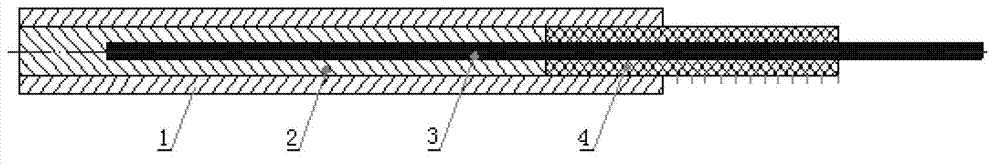

[0018] Specific embodiment one: the preparation method of a kind of EDTA modified carbon paste carbon nanotube film electrode in the present embodiment is carried out according to the following steps:

[0019] 1. Preparation of the electrode tube: Take an insulating tube with an inner diameter of 2-4 mm and a length of 4-5 cm as the electrode shell, clean it by ultrasonic waves, and insert a diameter of 1-3 mm and a length of 5 cm into one end of the electrode shell nozzle. ~7cm copper wire, so that 1~2cm copper wire is exposed outside the electrode shell as a lead wire, and then inserted into the copper wire insertion end of the electrode shell with an inner diameter of 1-3mm, an outer diameter of 2-4mm, and a length of 3-4cm The polytetrafluoroethylene tube, so that the polytetrafluoroethylene tube is exposed by 1.5 ~ 2cm, and the surface of the exposed polytetrafluoroethylene tube is marked with a scale along the direction of the tube length;

[0020] 2. Preparation of EDTA...

specific Embodiment approach 2

[0027] Embodiment 2: This embodiment differs from Embodiment 1 in that: in step 1, the insulating tube is a glass tube, a polytetrafluoroethylene tube or a plastic tube. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0028] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: in step 1, the inner diameter of the electrode tube is 3 mm, and the length is 5 cm. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com