Magneto-optical switch

A magneto-optical switch and optical component technology, applied in optics, nonlinear optics, optical waveguide coupling, etc., can solve the problems of difficult packaging, scattering, and many devices, so as to reduce volume, reduce production cost, and reduce the number of devices little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

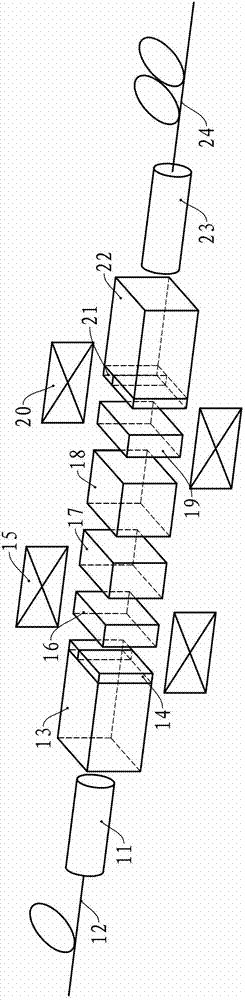

no. 1 example

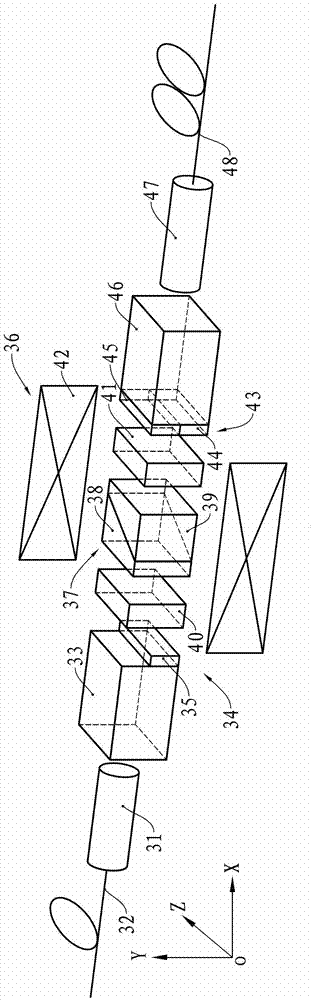

[0033] see figure 2 , the magneto-optical switch of this embodiment has a single-fiber collimator 31, and an optical fiber 32 is installed in the single-fiber collimator 31. In this embodiment, the single fiber collimator 31 is a single-core beam expanding fiber collimator, and the optical fiber 32 is a beam expanding fiber. At the exit end of the single-fiber collimator 31, a birefringent crystal 33, a half-wave plate assembly 34, an optical rotation assembly 36, a half-wave plate assembly 43, a birefringent crystal 46, and a double-fiber collimator 47 are sequentially arranged along the optical path direction, Two parallel optical fibers 48 are installed in the dual-fiber collimator 47, and the dual-fiber collimator 47 is a dual-core beam-expanding optical fiber collimator, and the two optical fibers 48 are both beam-expanding optical fibers.

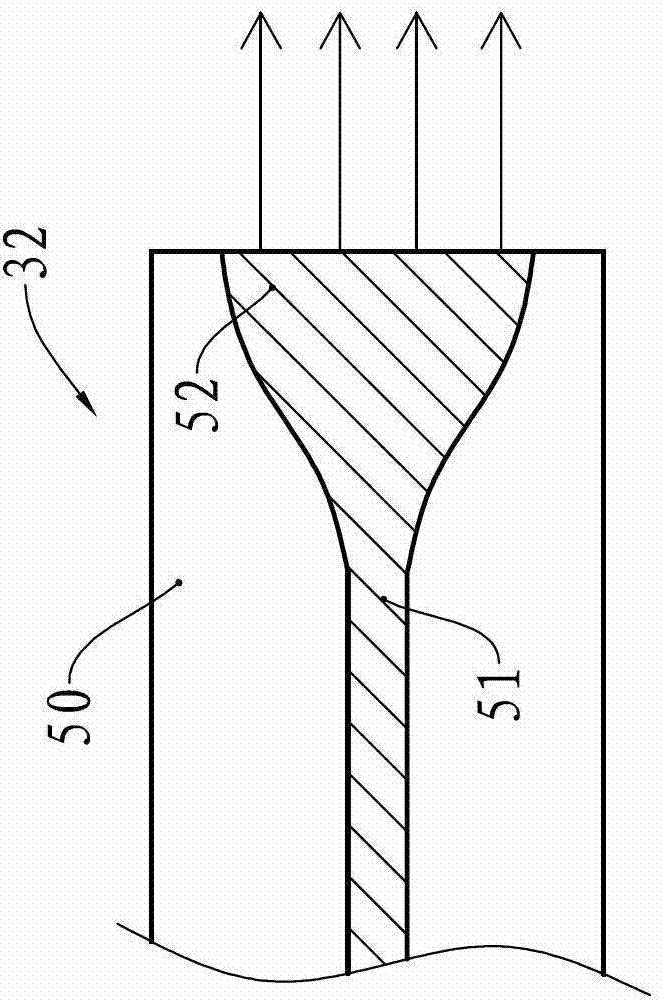

[0034] see image 3 , the expanded beam fiber 32 has a core 51 and a cladding 50 wrapped around the core 51, near the end of the ...

no. 2 example

[0059] see Figure 8 , this embodiment has a single-fiber collimator 61, and an optical fiber 62 is installed in the single-fiber collimator 61. At the exit end of the single-fiber collimator 61, a birefringent crystal 63, a half-wave plate assembly 64, an optical rotation assembly 67, a half-wave plate assembly 73, a birefringent crystal 76, and a double-fiber collimator 77 are sequentially arranged along the optical path direction, Two parallel optical fibers 78 are installed in the double fiber collimator 77 .

[0060] The single-fiber collimator 61 is a single-core beam-expanding fiber collimator, the double-fiber collimator 77 is a dual-core beam-expanding fiber collimator, and the optical fibers 62 and 78 are both beam-expanding optical fibers, that is, the fibers near the end of the optical fiber. The core diameter expands rapidly so that the spot diameter of the beam emerging from the optical fiber 62 is large.

[0061] The half-wave plate assembly 64 has two half-wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com