Bus current limiting control method and device for automotive brushless direct current motor

A brushed DC motor, current-limiting control technology, applied in the direction of excitation or armature current control, etc., to achieve the effect of easy realization, avoidance of damage, convenient promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

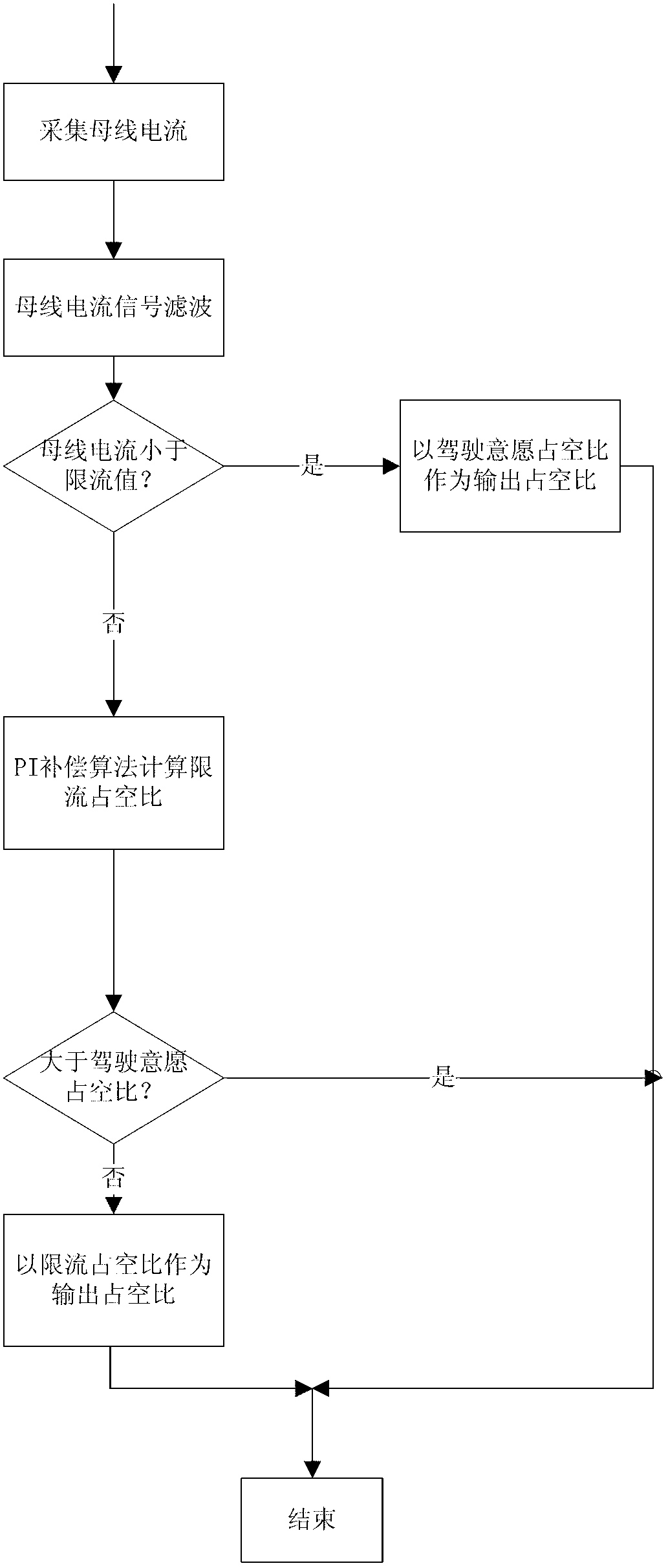

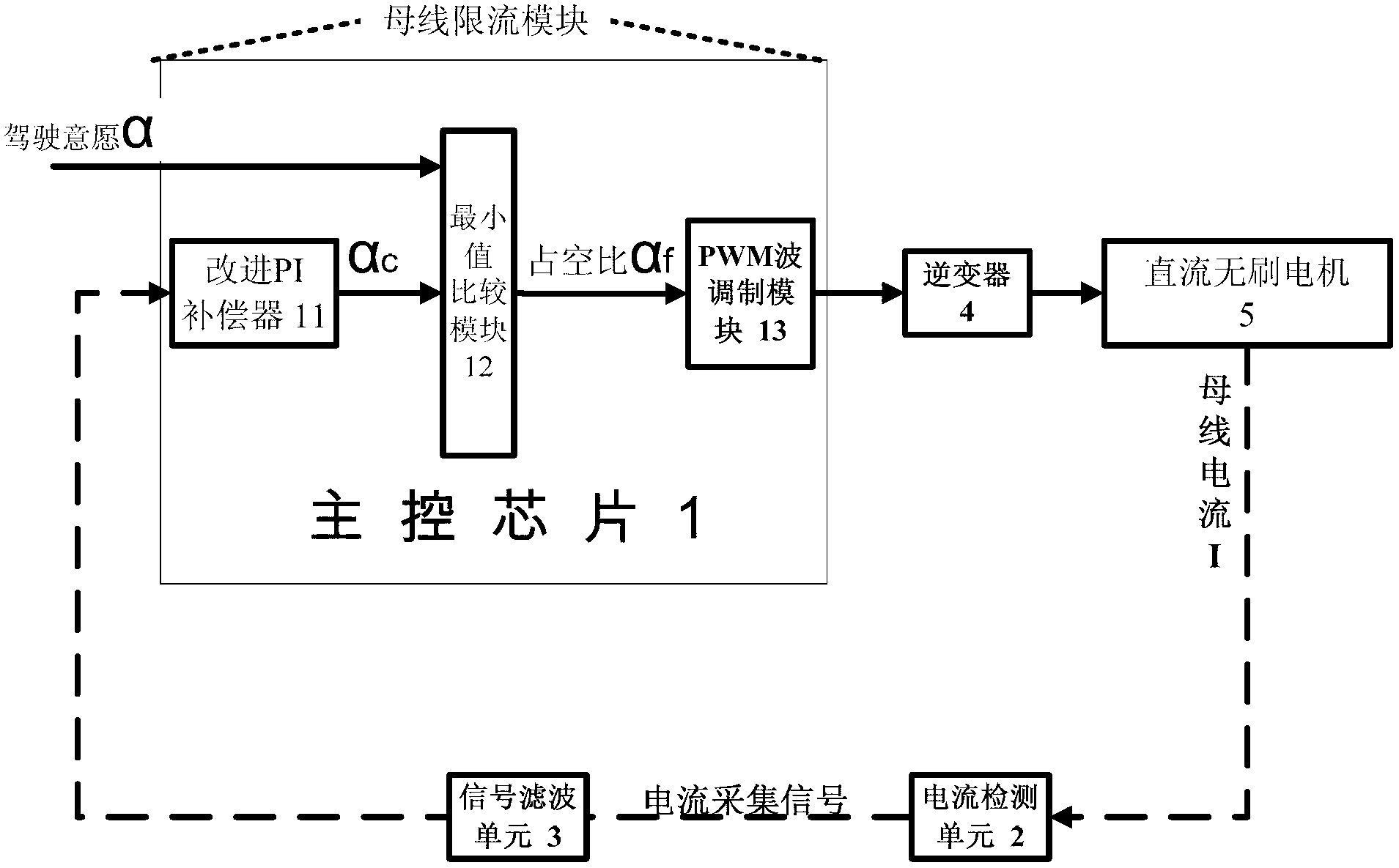

[0025] Such as figure 1 As shown, a vehicle brushless DC motor bus current limiting control method includes the following steps:

[0026] 1) The current detection module collects the bus current of the brushless DC motor and sends it to the signal filter module;

[0027] 2) The signal filter module filters the bus current collected by the current detection module and sends it to the main control chip;

[0028] 3) The main control chip judges whether the bus current is greater than the current limit value. If it is, the duty cycle of the driver's input is used as the output duty cycle, and the PWM wave is output to the inverter to drive the brushless DC motor. ; If not, go to step 4);

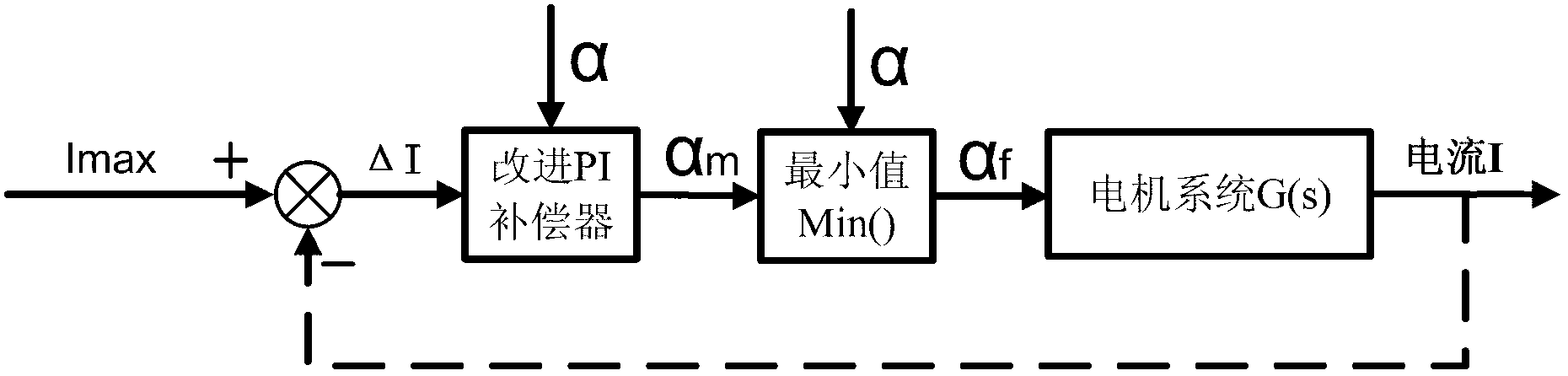

[0029] 4) The main control chip calculates and obtains the current-limiting duty cycle according to the bus current;

[0030] 5) The main control chip compares the current-limiting duty cycle and the driving will duty cycle, takes the smaller value as the output duty cycle, and modulates the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com