Color display element manufacturing method and color display element

A technology of color display and manufacturing method, which is applied in the direction of electrical components, optical components, instruments, etc., can solve the problems of low light utilization efficiency, waste of process cost coloring resist, damage to brightness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

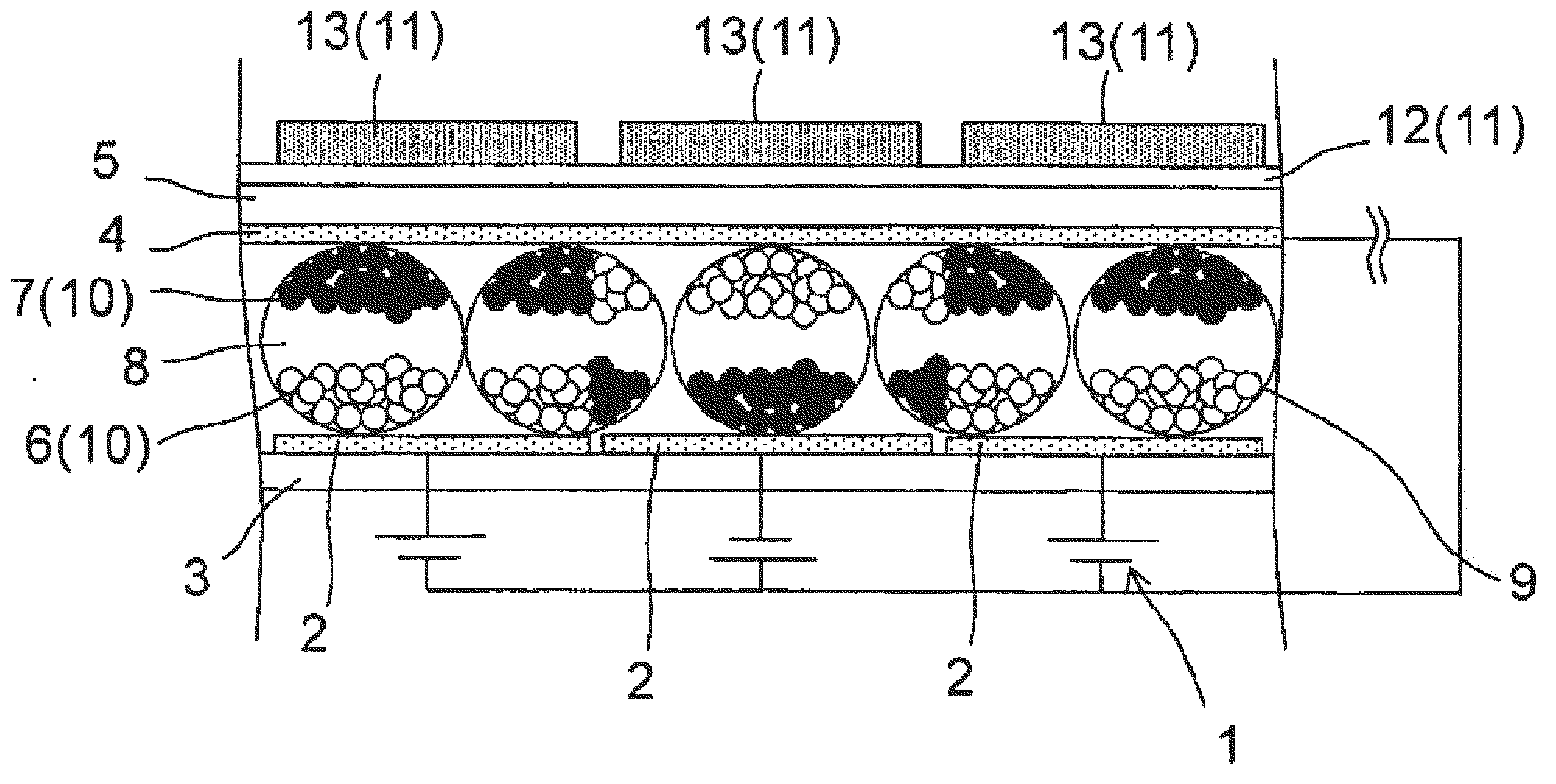

Embodiment 1

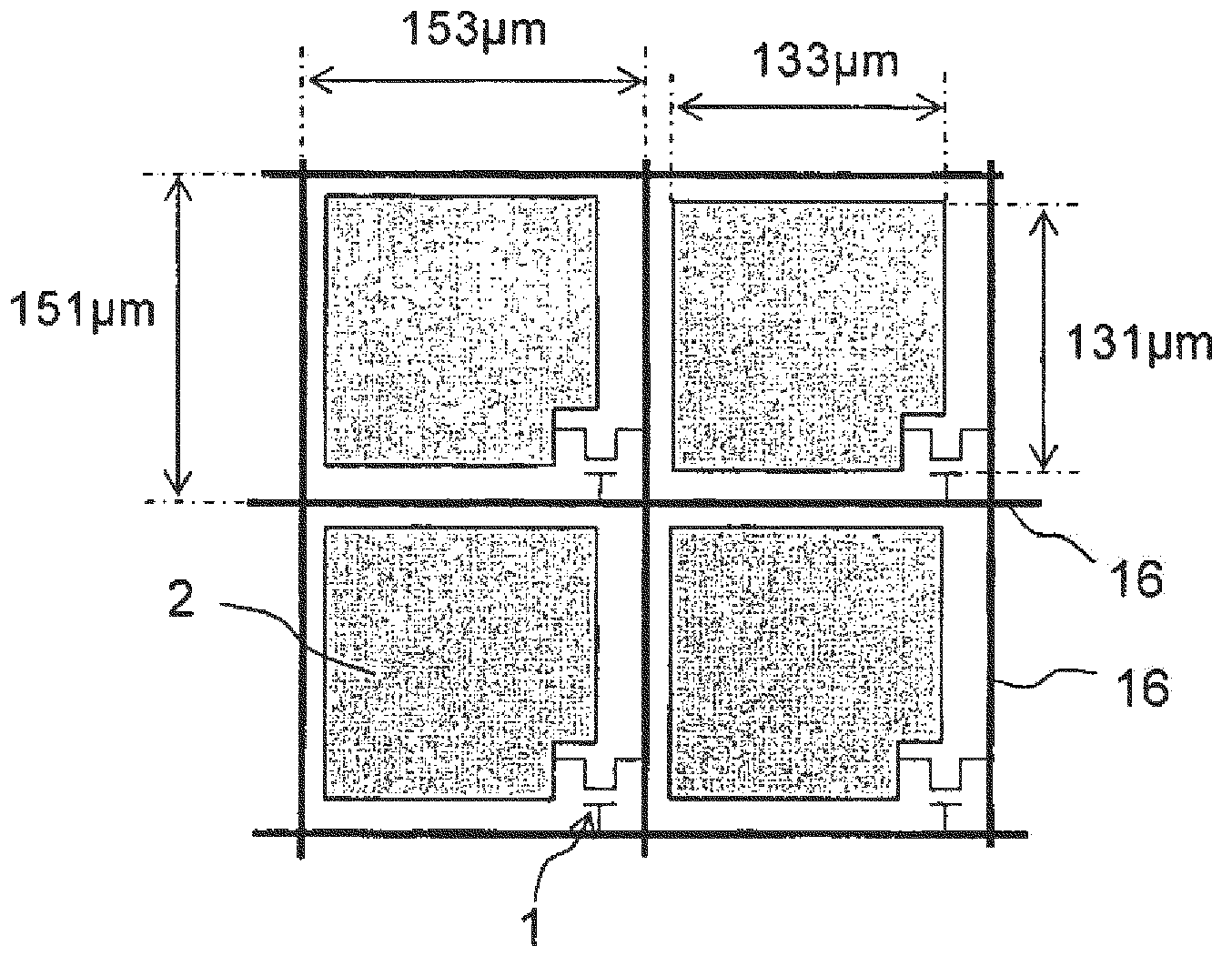

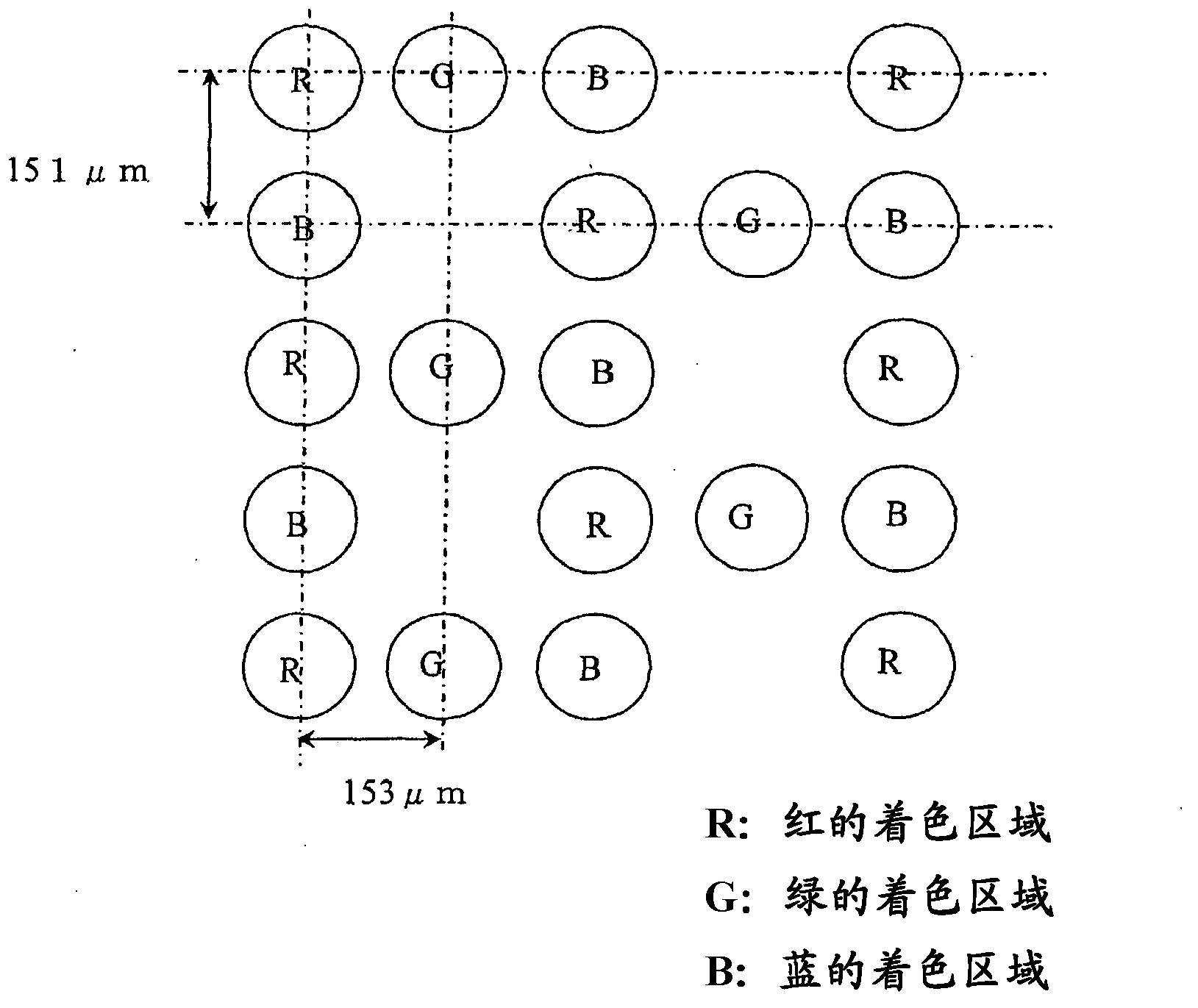

[0079] Using an inkjet head KM512L manufactured by Konica Minolta (equipped with nozzles 512 holes capable of discharging 42 pl), the aforementioned colored inkjet inks R1, G1, and B1 were applied on a PET film for inkjet produced by Toyobo as a transparent support substrate (model number GT701#130) above as image 3 A color filter of 6 inches was produced by drawing at a pitch as shown to obtain a colored area. After drawing, drying was performed at 80° C. for 3 minutes on a hot plate, 1500 mJ (I-ray standard) exposure was performed with an ultraviolet exposure machine, and firing was performed at 140° C. for 30 minutes. The diameter and height of each droplet during processing are measured. The overlapping of the three colors was not seen at all, and the convex shape was shown as shown in Table 3, and the area of the colored region was 90% or less with respect to the pixel electrode of the TFT substrate.

[0080] [table 3]

[0081]

Embodiment 2 and Embodiment 3

[0083] In addition to drawing each colored ink twice at the same position by overlapping the same dotted position as in Example 1 (Example 2), or by drawing 3 times and drawing by 3 drops Except for (Example 3), color filters were produced in the same manner as in Example 1 (Table 4). It can be seen that the convex shape is shown without overlapping in any of the colors, and that the height becomes higher as the number of drops increases. In addition, the area of the colored region is 90% or less with respect to the pixel electrode of the TFT substrate.

[0084] [Table 4]

[0085]

Embodiment 4

[0087] A 6-inch color filter was produced in the same manner as in Example 1 except that a 0.7 mm-thick alkali-free glass plate (AN-100 manufactured by Asahi Glass Co., Ltd.) was used as the transparent support substrate (Table 5). It can be seen that colored pixels are formed without overlapping in any color. In addition, the area of the colored region is 90% or less with respect to the pixel electrode of the TFT substrate.

[0088] [table 5]

[0089]

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com