Method and system for sand planting of diamond wire saw

A diamond wire saw and diamond particle technology, which is applied in the field of diamond wire saw sand planting methods and systems, can solve problems such as shedding, insufficient adhesion, and uneven distribution of diamond particles, so as to prolong the service life, ensure cutting accuracy and cutting efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

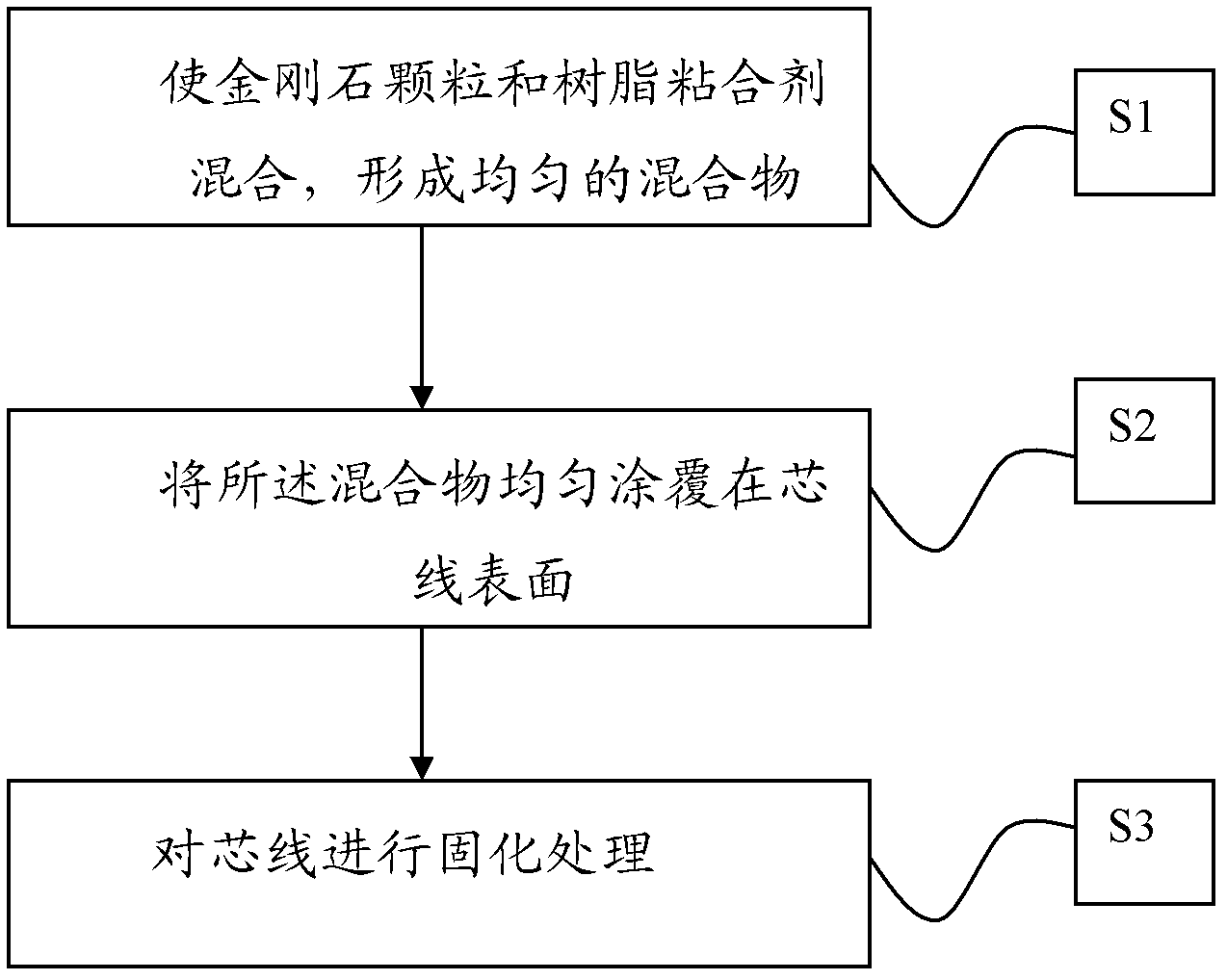

[0045] refer to figure 2 , figure 2 It is a schematic flow chart of a diamond wire saw sand planting method provided by an embodiment of the present invention, and the method includes steps:

[0046] Step S1: mixing the diamond particles and the resin binder to form a homogeneous mixture.

[0047] Step S2: uniformly coating the mixture on the surface of the core wire.

[0048] Through the above step S1, the diamond particles and the resin binder are first fully mixed, so that during the coating process, the diamond particles can be evenly distributed on the surface of the core wire, thereby ensuring the uniformity of the distribution of diamond particles on the surface of the core wire.

[0049] Step S3: Curing the core wire.

[0050] During this process, the core wire is cured and molded to evaporate the volatile components in the resin binder, and the exposure rate of diamond particles on the surface of the core wire after curing can be controlled according to the solid...

Embodiment 2

[0053] On the basis of Embodiment 1, the present invention provides another diamond wire saw sand planting method, the method comprising steps:

[0054] Step S21: mixing the diamond particles and the resin binder according to a preset ratio to form a uniform mixture.

[0055] By thoroughly mixing the diamond particles and the resin binder in advance, it can not only ensure that the diamond particles are evenly distributed on the surface of the core wire in the next step of the coating process, but also can adjust the relative relationship between the diamond particles and the resin binder. Ratio, and then control the distribution density of diamond particles on the surface of the core wire.

[0056] Step S22: coating the mixture on the surface of the core wire, while adjusting the thickness of the mixture on the surface of the core wire.

[0057] The step S22 specifically includes: after coating the mixture on the surface of the core wire, adjusting the diameter of the core w...

Embodiment 3

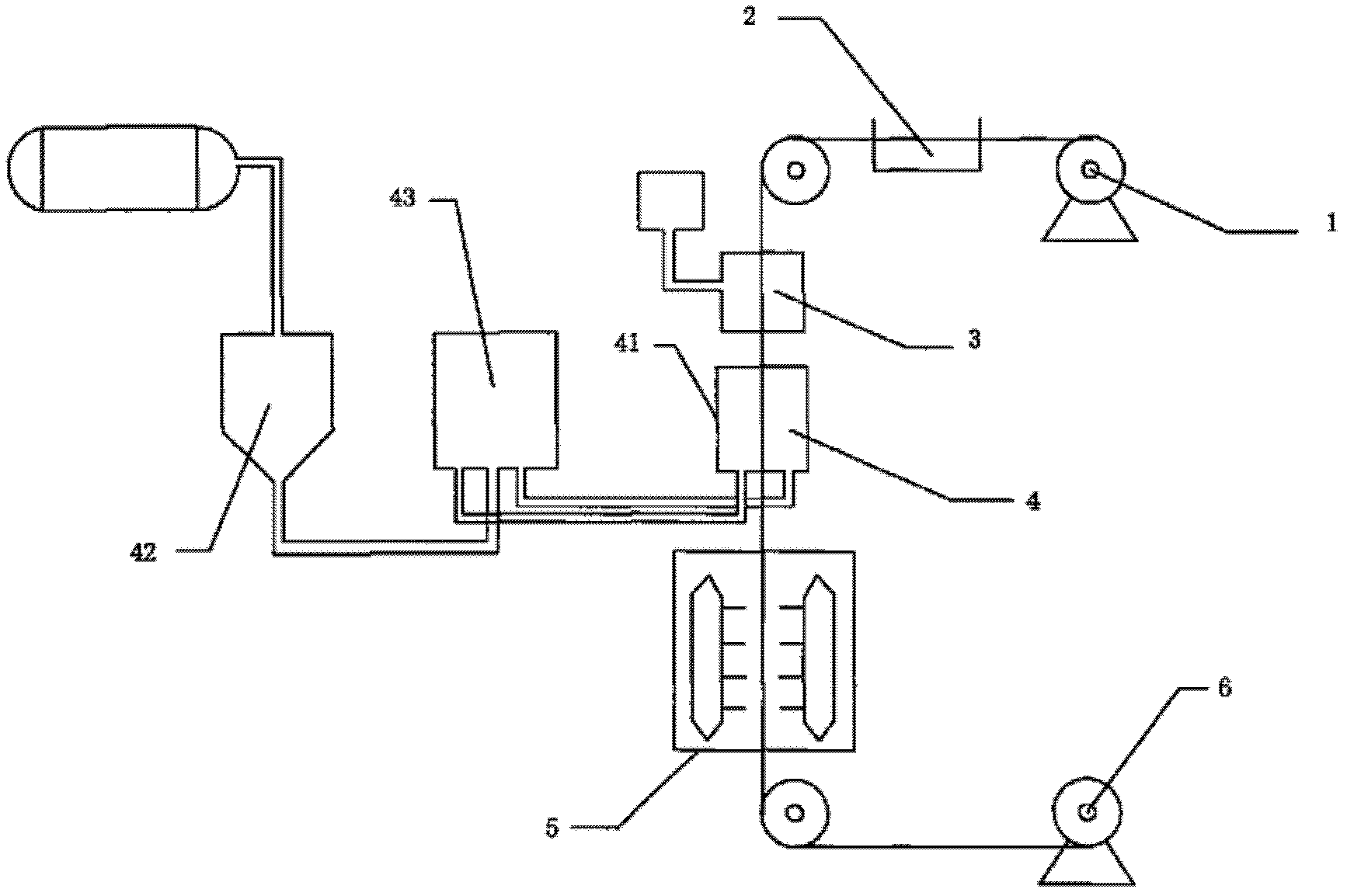

[0064] The diamond wire saw sand planting method provided by the present invention has been described in detail above, and the diamond wire saw sand planting system provided by the present invention will be described in detail below.

[0065] refer to image 3 , image 3 It is a structural schematic diagram of a diamond wire saw sand planting system provided by the present invention. The diamond wire saw sand planting system includes: a premixing device 101 for stirring diamond particles and a resin binder to form a uniform mixture; A coating device 102 for uniformly coating the surface of the core wire with the mixture extracted from the premixing device 101; a curing device 103 for curing the core wire coated with the mixture on the surface.

[0066] Preferably, the diamond wire saw sand planting system in the embodiment of the present invention also includes: a backflow device 104, the backflow device 104 is used to collect the diamond particles not coated on the surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com