Process method and system for recovering water from lignite drying flue gas

A process method and water recovery technology, applied in separation methods, chemical instruments and methods, steam condensation, etc., can solve the problems of large floor area, high investment in fixed assets and high operating costs, and achieve small floor space and alleviate water shortage , Conducive to the effect of system reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

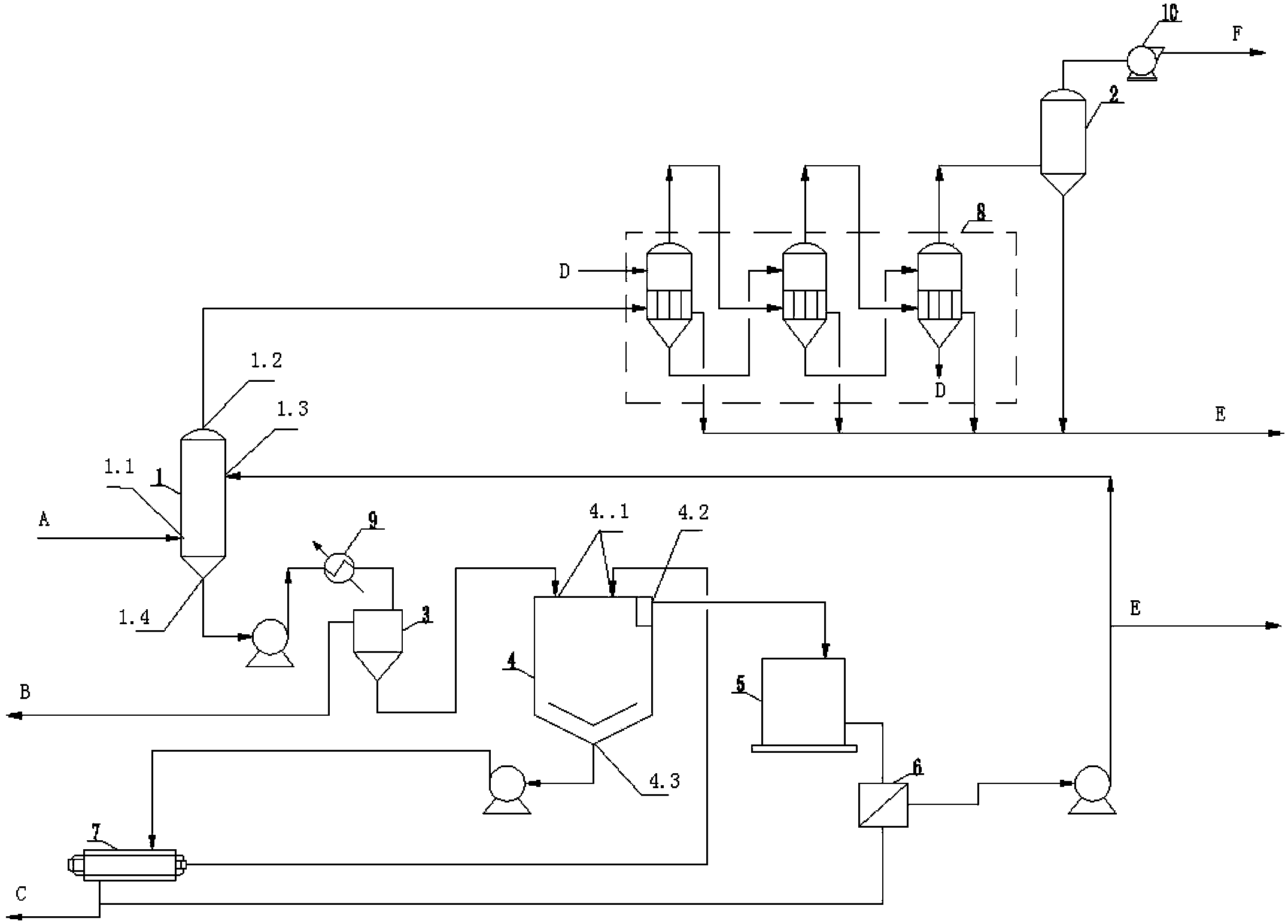

[0020] refer to figure 1 , the scrubber 1 is provided with flue gas inlet 1.1, flue gas outlet 1.2, process water inlet 1.3 and gray water outlet 1.4, gray water outlet 1.4 is successively connected to gray water cooler 9, oil-water separator 3, clarifier 4, Ash tank 5, filter 6 and process water inlet 1.3. The flue gas outlet 1.2 is sequentially connected to the series evaporator group 8, the vapor-liquid separation tank 2 and the induced draft fan 10 through pipelines. The clarifier 4 is provided with a gray water inlet 4.1, a gray water outlet 4.2 and a mortar outlet 4.3, the gray water inlet 4.1 is connected to the oil-water separator, the gray water outlet 4.2 (overflow outlet) is connected to the gray water tank 5, and the mortar The outlet 4.3 is connected with the gray water inlet 4.1 through the screw machine 7. Valves, water pumps, etc. can be set on the pipeline as required, which is a conventional technology and will not be described in detail here.

[0021] wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com