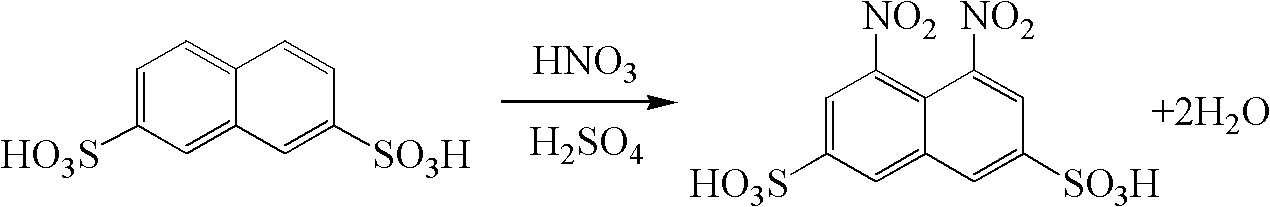

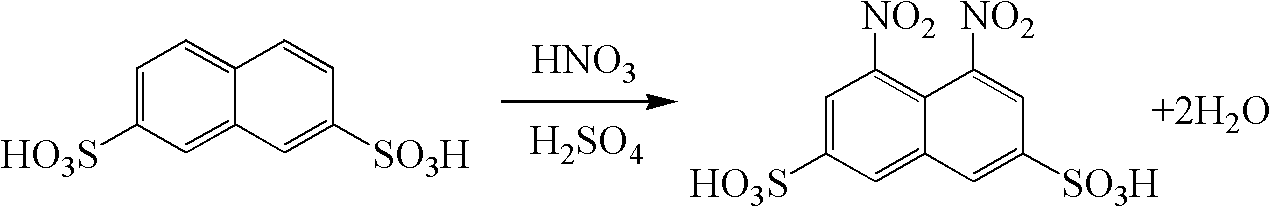

Clean preparation method of 1, 8-dinitro-3, 6-naphthalenedisulfonic acid

A technology of naphthalene disulfonic acid and dinitro, which is applied in 1 field, can solve the problems of large nitrification wastewater and discharge, and achieve high yield and simple and practical treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Dissolve 1008 grams of 2,7-naphthalene disulfonic acid in 3L of industrial sulfuric acid with a mass fraction of 93%, keep the temperature at 0-5°C, add 630 grams of 98% fuming nitric acid dropwise within 2 hours, and keep the reaction for 2 hours until nitration The reaction is complete. 4600ml of water was added dropwise to the reactant, and then the temperature was raised to 95-100° C., and the air was continuously fed under stirring, and the temperature was lowered after keeping the temperature for 3 hours. Filtration at room temperature yielded 1976 g of light yellow 1,8-dinitro-3,6-naphthalene disulfonic acid filter cake with a purity of 98.83%, a solid content of 60.87%, and a yield of 90.91%. Obtain 6.87L of reddish-brown nitration mother liquor, COD value 47000mg / L, for subsequent treatment.

Embodiment 2

[0024] Take 1 L of the nitration mother liquor obtained in Example 1, stir rapidly at room temperature (360r / min, the same below), add 0.5 g of the previously prepared flocculant, and reduce the stirring speed after ten minutes (60r / min, the same below). After 1 hour, it was filtered, and the color of the mother liquor changed from reddish brown to light yellow. The COD value is 2200mg / L.

Embodiment 3

[0026] Add 0.1 g of the above-prepared flocculant to 1 L of nitration mother liquor with rapid stirring at 10°C, and reduce the stirring speed after ten minutes. Filter after 2 hours, the filtrate is light yellow, and the COD value is 3700mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com