Wide temperature range and high damping ethylene-propylene-diene-terpolymer rubber preparation method

An EPDM rubber and high damping technology, which is applied in the field of rubber preparation, can solve problems such as endangering safety, reducing operation accuracy, and uncontrollability, and achieves good processing performance and model fluidity, increased temperature range, and mixing Colloidal soft effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A preparation method of EPDM rubber with wide temperature range and high damping, comprising the steps of:

[0022] (1) The wide temperature range high damping EPDM rubber is composed of the following raw materials in parts by weight: EPDM rubber 100, dicumyl peroxide 3, zinc oxide 3, stearic acid 1;

[0023] (2) Add the raw materials in the above parts by weight into a torque rheometer, mix for 10 minutes at a temperature range of 100°C, and rotate at a speed of 100 rpm to obtain a mixed rubber;

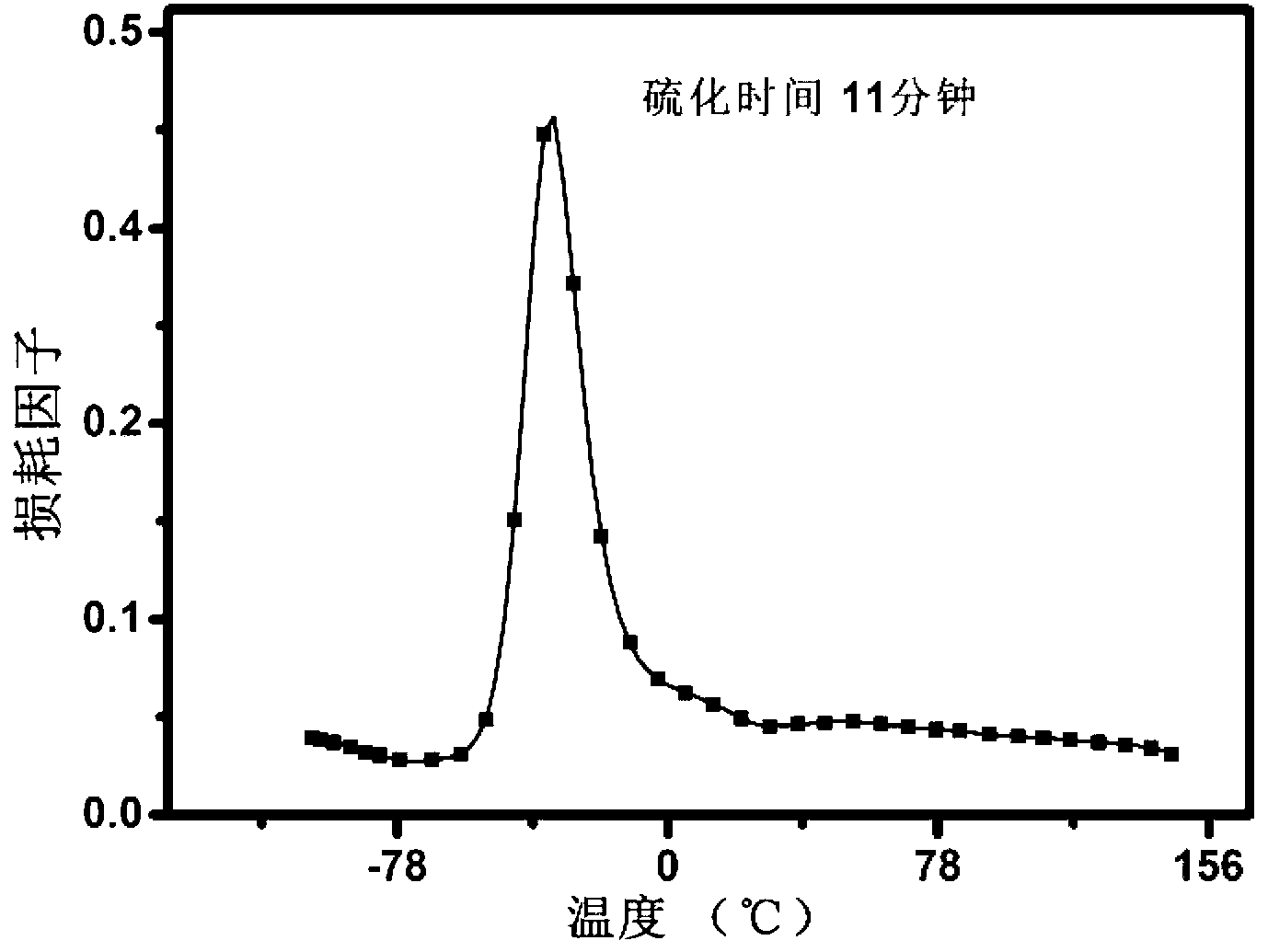

[0024] (3) Put the above mixed rubber for 24 hours, then put it on a flat vulcanizer, and press it for 11 minutes under the temperature range of 160 ° C and 11 MPa pressure to obtain the required wide temperature range and high damping EPDM rubber;

[0025] A 2mm thick cuboid sample was prepared, and the dynamic mechanical test was carried out using a dynamic mechanical analyzer (DMA). Test conditions: frequency 5Hz, temperature -80°C to 200°C, heating rate 2°C / min, tensile...

Embodiment 2

[0027] (1) The wide temperature range high damping EPDM rubber is composed of the following raw materials in parts by weight: EPDM rubber 100, dicumyl peroxide 3, zinc oxide 3, stearic acid 1;

[0028] (2) Add the raw materials in the above parts by weight into a torque rheometer, mix for 10 minutes at a temperature range of 100°C, and rotate at a speed of 100 rpm to obtain a mixed rubber;

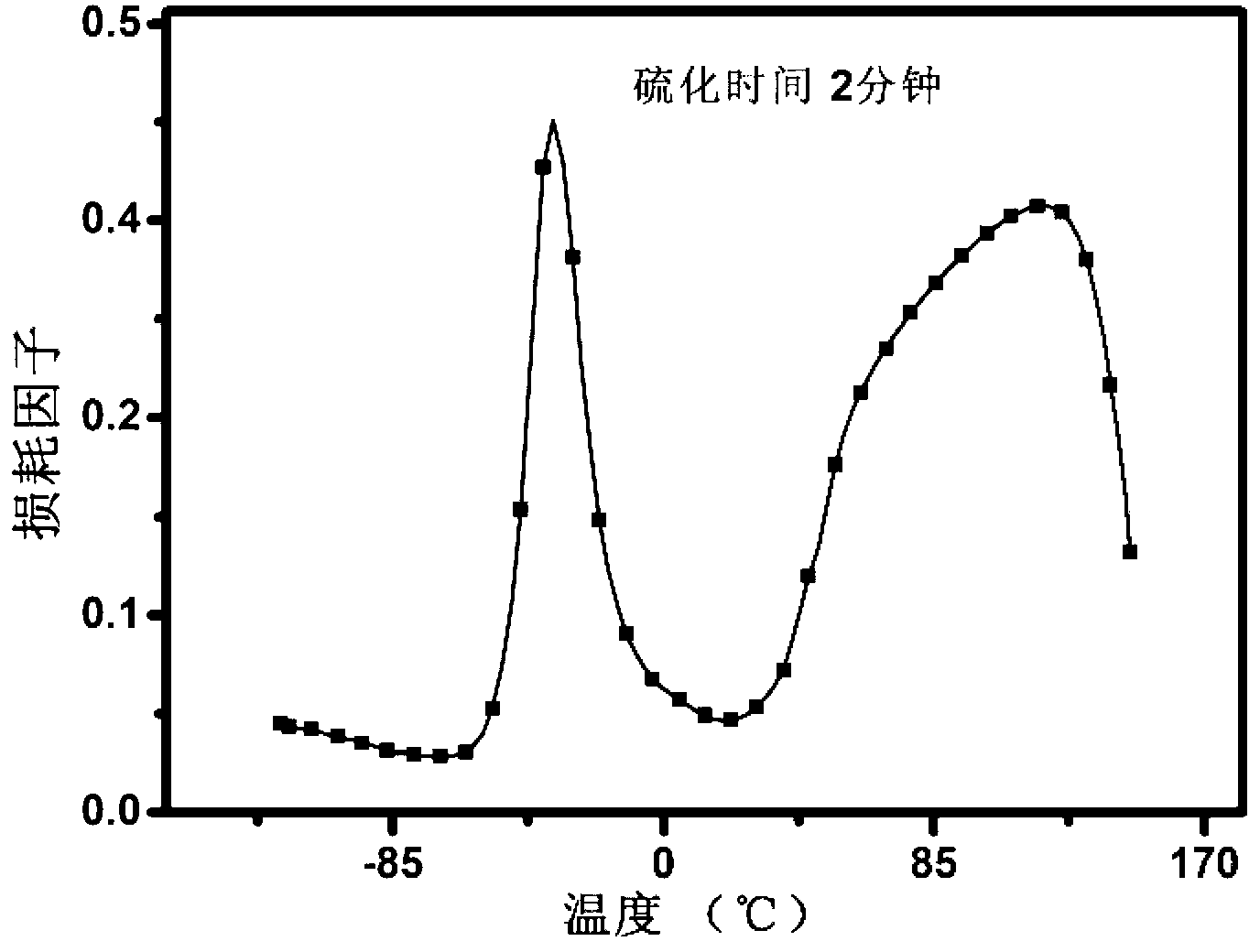

[0029] (3) Put the above mixed rubber for 24 hours, then place it on a flat vulcanizing machine, under the temperature range of 160 ℃, under the pressure of 11MPa and hot press for 2 minutes, you can get the required wide temperature range and high damping ternary B Propylene rubber;

[0030] A 2mm thick cuboid sample was prepared, and the dynamic mechanical test was carried out using a dynamic mechanical analyzer (DMA). Test conditions: frequency 5Hz, temperature -80°C to 200°C, heating rate 2°C / min, tensile mode, test results see figure 2 . The loss peak area (TA) is used to measure ...

Embodiment 3

[0032] (1) The wide temperature range high damping EPDM rubber is composed of the following raw materials in parts by weight: EPDM rubber 100, dicumyl peroxide 3, zinc oxide 3, stearic acid 1;

[0033] (2) Add the raw materials in the above parts by weight into a torque rheometer, mix for 10 minutes at a temperature range of 100°C, and rotate at a speed of 100 rpm to obtain a mixed rubber;

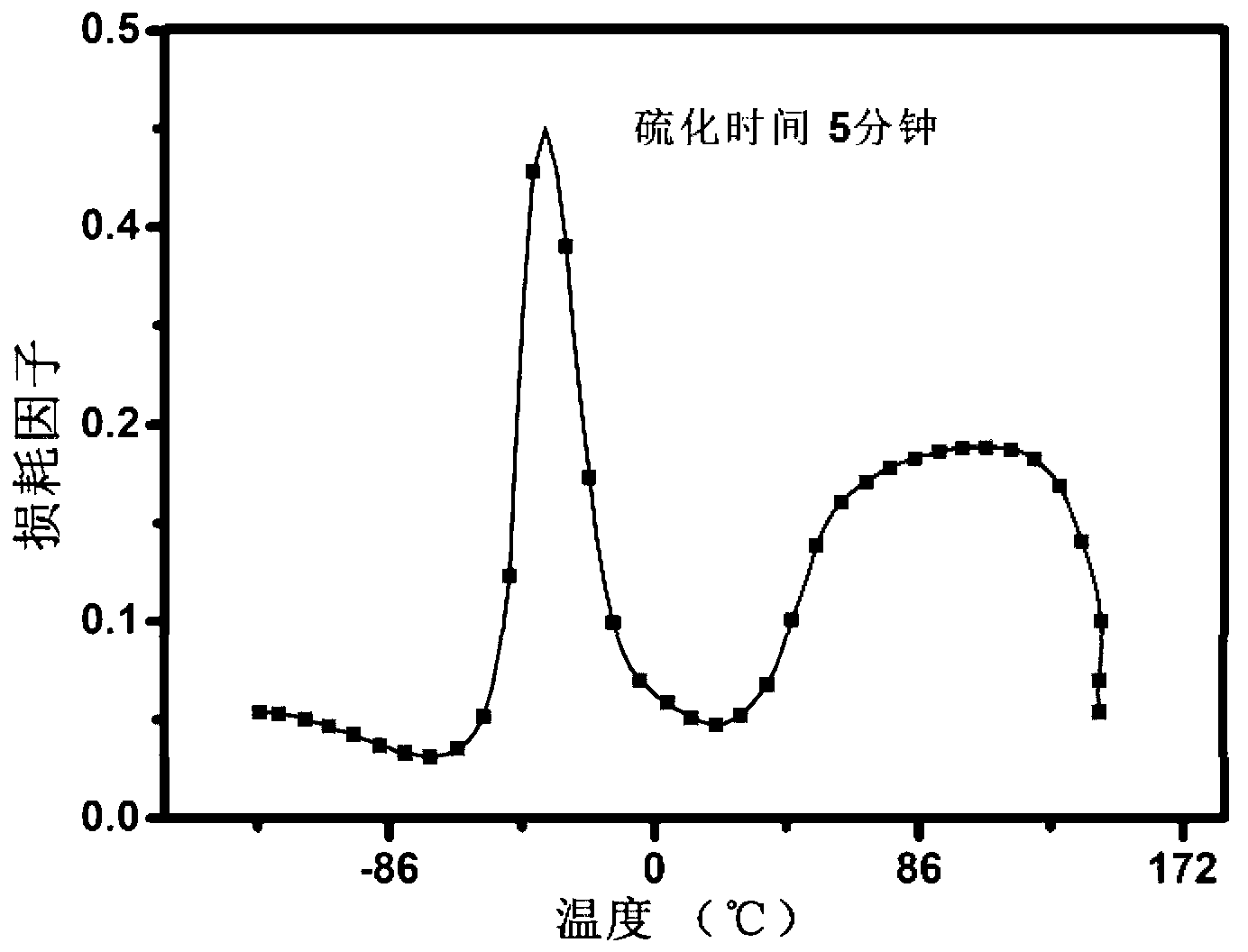

[0034] (3) Park the above compounded rubber for 24 hours, then place it on a flat vulcanizing machine, under-vulcanize and hot press for 5 minutes under the temperature range of 160°C and 11MPa pressure, and the required wide temperature range and high damping EPDM can be obtained rubber;

[0035] A 2mm thick cuboid sample was prepared, and the dynamic mechanical test was carried out using a dynamic mechanical analyzer (DMA). Test conditions: frequency 5Hz, temperature -80°C to 200°C, heating rate 2°C / min, tensile mode, test results see image 3 . The loss peak area (TA) is used to meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com