Heater of ingot furnace

A technology for heaters and ingot casting furnaces, applied in chemical instruments and methods, crystal growth, and self-melting liquid pulling methods, etc., can solve incomplete melting, quasi-single crystal area becomes smaller, and protect seed crystals from incomplete melting, etc. problem, to achieve the effect of increasing the crystal growth rate, good single crystal area, and less geometric space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following are specific embodiments of the present invention, which further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

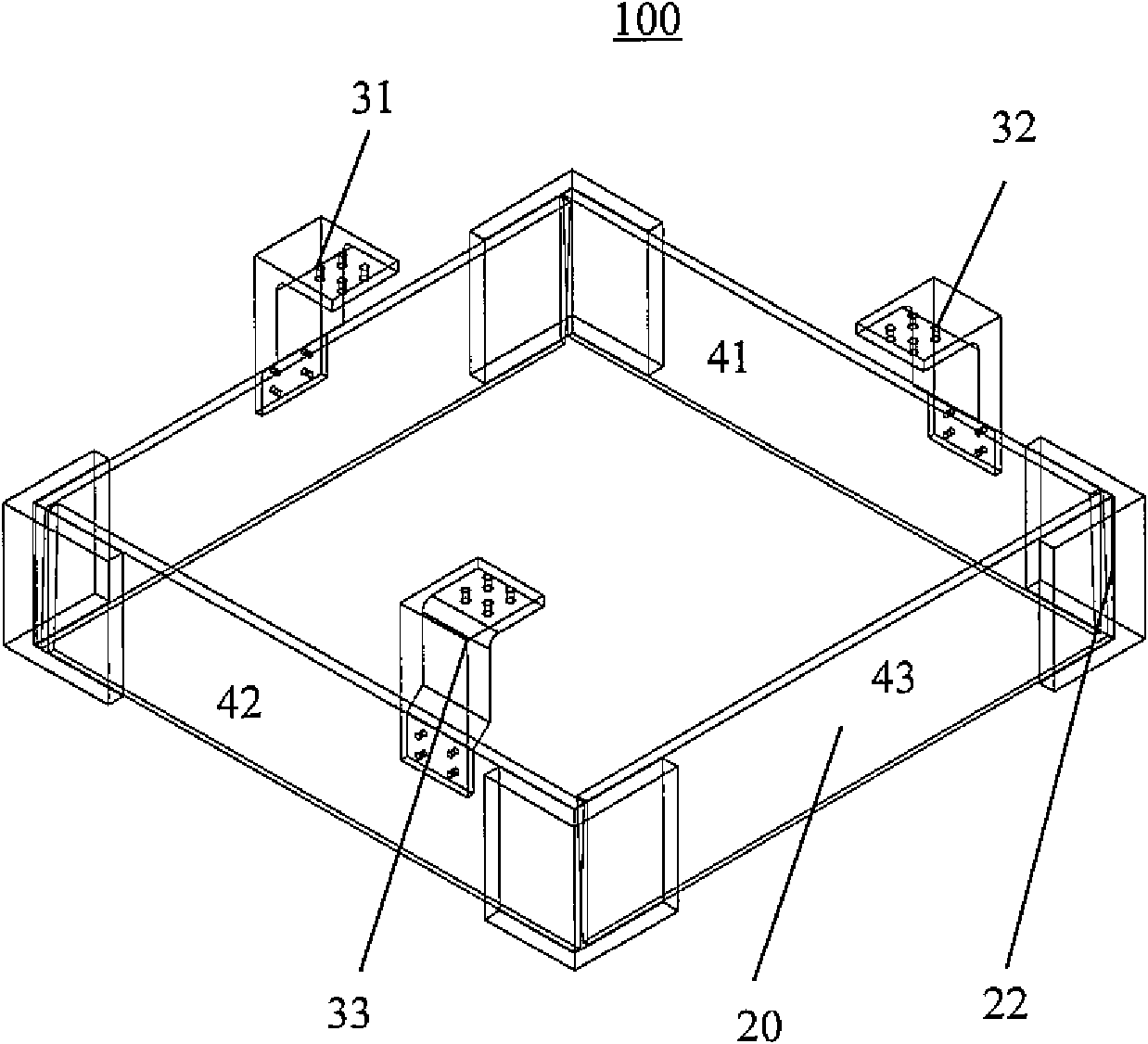

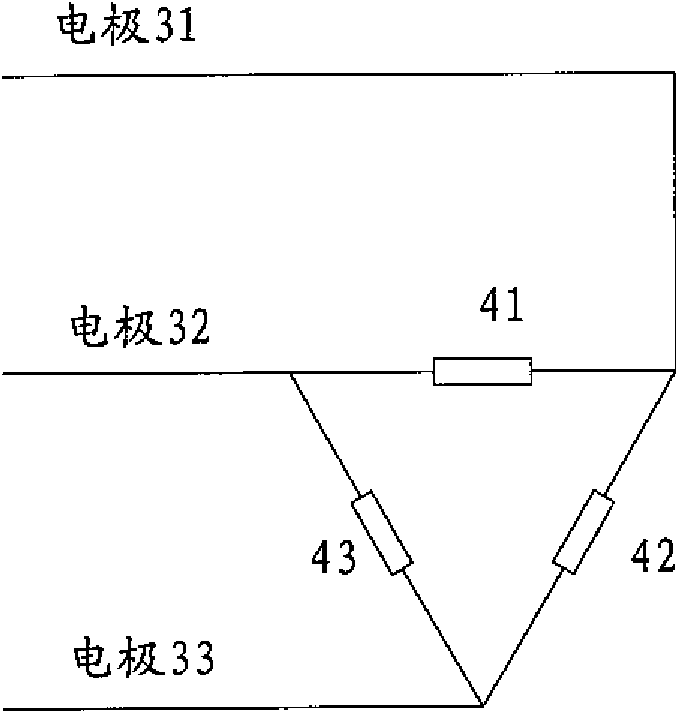

[0031] figure 1 A heater 100 is shown, which is a resistance heater formed by connecting a plurality of heating blocks through connecting plates and adding electrodes thereon. Specifically, the four heating blocks 20 are connected together by connecting plates 22 to form a circumferential closed structure. Wherein, the heating blocks 20 are all made of the same carbon-carbon composite material, and the connecting plate 22 is made of graphite or carbon-carbon composite material. The above-mentioned circumferential closed structure is equipped with electrodes 31, 32 and 33 and is divided into three sections of resistance by them, that is, the heat generating body part 41 between the electrodes 31 and 32, the heat generating body part between the electrodes 31 and 33 The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com