Si-substrate patterned graphene preparation method based on Ni film annealing

A patterned graphene and substrate technology, applied in the field of microelectronics, can solve the problems of complex graphics, inaccessibility, and high cost of template preparation, and achieve the effect of smooth surface, low porosity, and guaranteed device performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Step 1: Remove sample surface contamination.

[0035] (1.1) Clean the surface of the 4-inch Si substrate, that is, use NH 4 OH+H 2 o 2 Soak the sample in the reagent for 10 minutes, take it out and dry it to remove the organic residue on the surface of the sample;

[0036] (1.2) Then use HCl+H 2 o 2 The reagent soaked the sample for 10 minutes, took it out and dried it to remove ionic contamination.

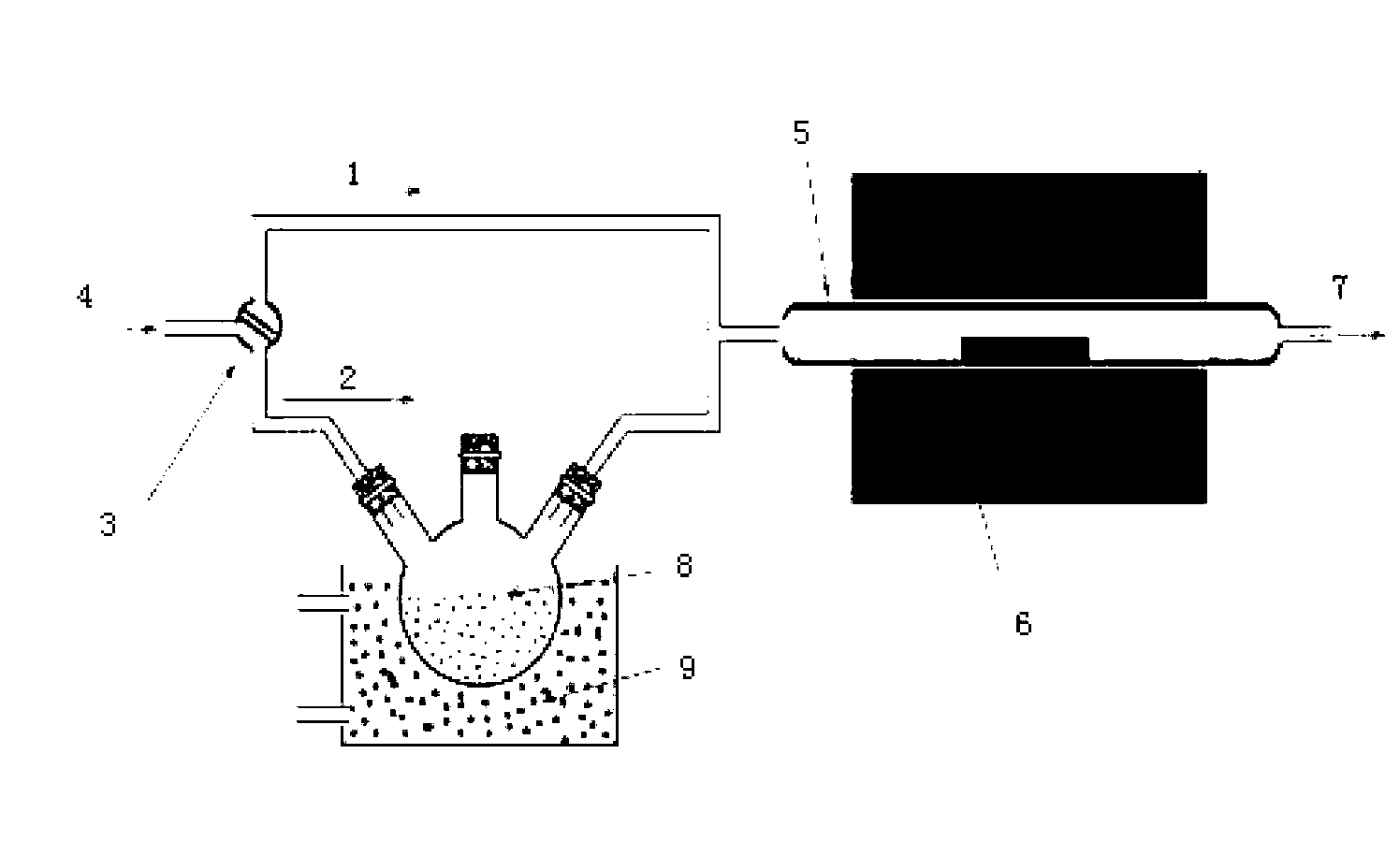

[0037] Step 2: Vacuumize the reaction chamber.

[0038] Put the Si substrate substrate into the reaction chamber of the CVD system, and evacuate the reaction chamber to 10 -7 mbar level.

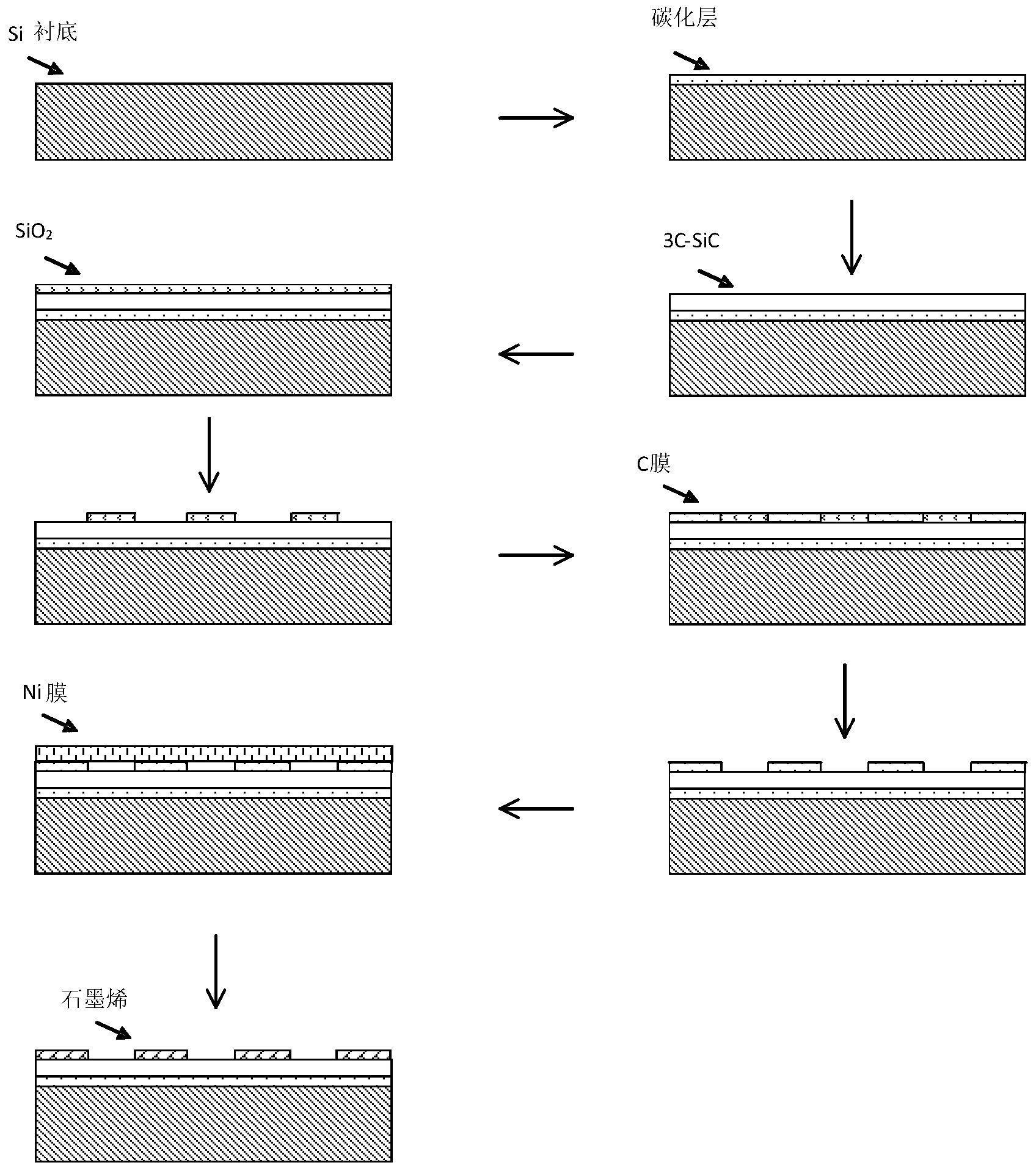

[0039] Step 3: growing the carbonized layer.

[0040] in H 2 In the case of protection, the temperature of the reaction chamber is raised to the carbonization temperature of 1000 ° C, and then the flow rate of 35ml / min is introduced into the reaction chamber. 3 h 8 , grow a layer of carbonized layer on the Si substrate, the growth time is 8min.

[0041] Step 4: growing a 3C-S...

Embodiment 2

[0066] Step 1: Remove sample surface pollutants.

[0067] Clean the surface of the 8-inch Si substrate substrate, that is, use NH 4 OH+H 2 o 2 Soak the sample in the reagent for 10 minutes, take it out and dry it to remove the organic residue on the surface of the sample; then use HCl+H 2 o 2 The reagent soaked the sample for 10 minutes, took it out and dried it to remove ionic contamination.

[0068] Step 2: Vacuumize the reaction chamber.

[0069] Same as Step 2 of Example 1.

[0070] Step 3: growing a carbonized layer.

[0071] in H 2 In the case of protection, the temperature of the reaction chamber is raised to the carbonization temperature of 1100 ° C, and then the flow rate of 35 ml / min is introduced into the reaction chamber. 3 h 8 , grow a layer of carbonized layer on the Si substrate, the growth time is 6min.

[0072] Step 4: growing a 3C-SiC thin film on the carbide layer.

[0073] Rapidly raise the temperature of the reaction chamber to the growth temper...

Embodiment 3

[0091] Step A: Clean the surface of the 12-inch Si substrate, that is, use NH 4 OH+H 2 o 2 Soak the sample in the reagent for 10 minutes, take it out and dry it to remove the organic residue on the surface of the sample; then use HCl+H 2 o 2 The reagent soaked the sample for 10 minutes, took it out and dried it to remove ionic contamination.

[0092] Step B: Same as Step 2 of Example 1.

[0093] Step C: In H 2 In the case of protection, the temperature of the reaction chamber is raised to the carbonization temperature of 1200°C, and then the flow rate of 35ml / min is introduced into the reaction chamber 3 h 8 , for 4 min to grow a carbonized layer on the Si substrate.

[0094] Step D: Rapidly raise the temperature of the reaction chamber to the growth temperature of 1350°C, and feed the SiH with flow rates of 35ml / min and 70ml / min respectively. 4 and C 3 h 8 , for 3C-SiC thin film heteroepitaxial growth for 60min; then in H 2 Gradually cool down to room temperature u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com