A SiC Junction Barrier Schottky Diode Device with Ladder Termination

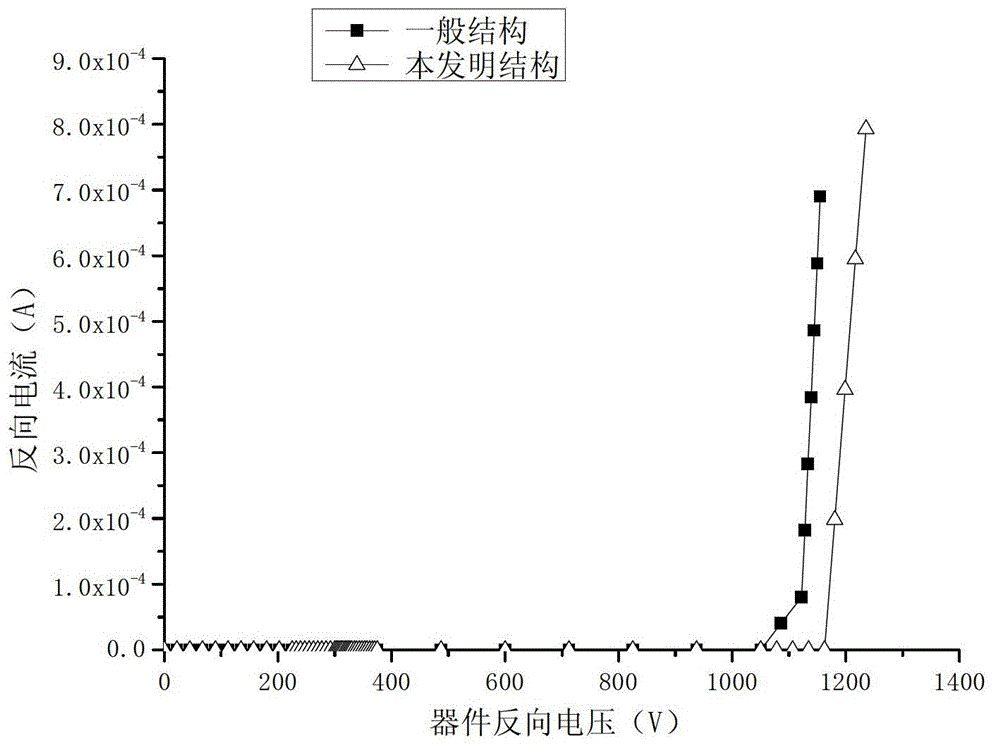

A technology of junction barrier Schottky and silicon carbide, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of increasing the forward voltage drop and increasing the forward conduction resistance of the device, so as to reduce the local high field and improve the Inverse characteristic curve, effect of high withstand voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

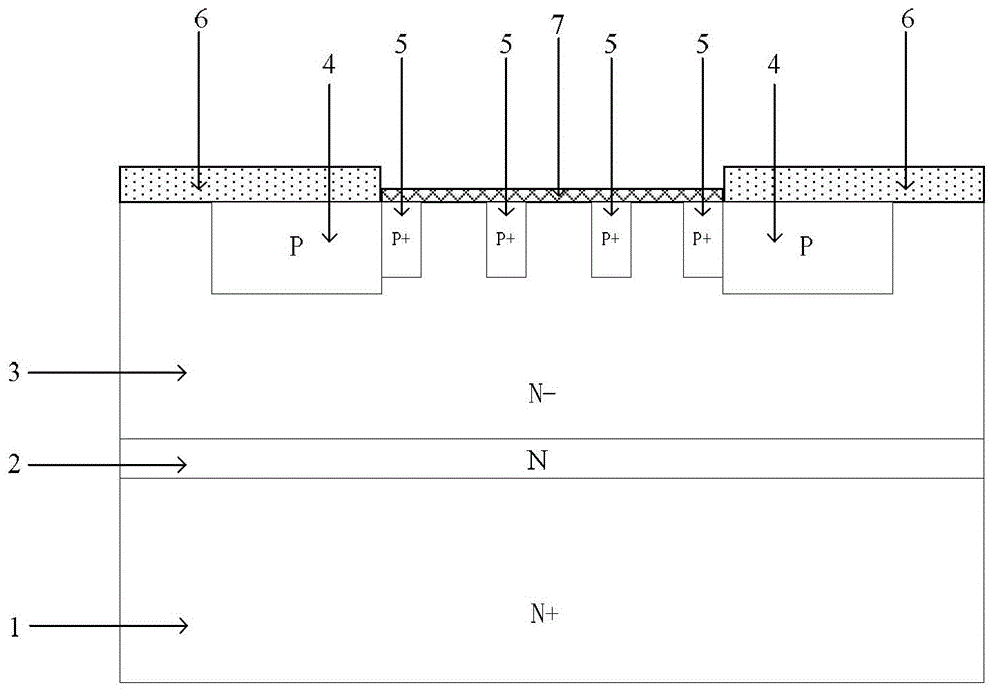

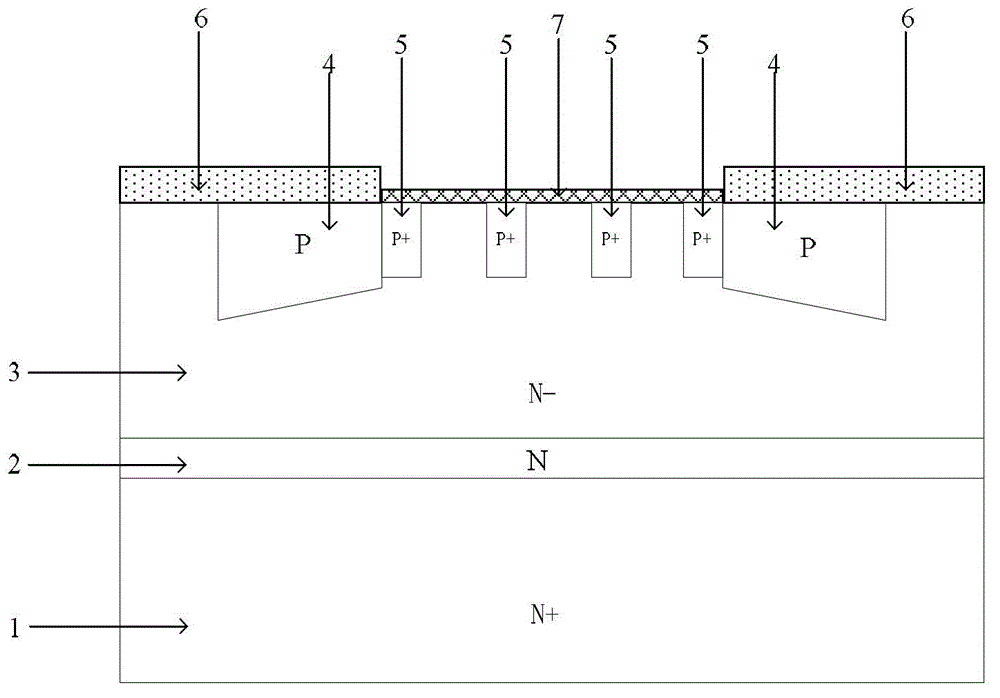

[0020] Attached below figure 2 , the present invention is described in detail, a silicon carbide junction barrier Schottky diode device with a ladder-shaped terminal, the silicon carbide junction barrier Schottky diode device with a ladder-shaped terminal is a symmetrical structure, including: an N+ type substrate 1, An N-type transition epitaxial layer 2 is provided on the N+ type substrate 1, an N-type epitaxial layer 3 is provided on the N-type transition epitaxial layer 2, and two P-type junctions are provided above the inside of the N-type epitaxial layer 3. Terminal 4 and 4 equally spaced P+ type body regions 5, and the inner edges of the two P type junction terminals 4 are offset against the outer edges of the adjacent two P+ type body regions 5, and the upper surface of the N-type epitaxial layer 3 is set There are two field oxide layers 6 and metal layers 7, the inner boundaries of the two P-type junction terminals 4 are respectively aligned with the inner boundaries...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com