Microgravity test system and test method for fluid transmission performance verification of plate tanks

A technology of fluid transmission and microgravity, applied in transportation and packaging, simulators of space navigation conditions, space navigation equipment, etc., can solve problems such as leaks, and achieve the effects of convenient camera observation, easy model replacement, and reasonable test methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

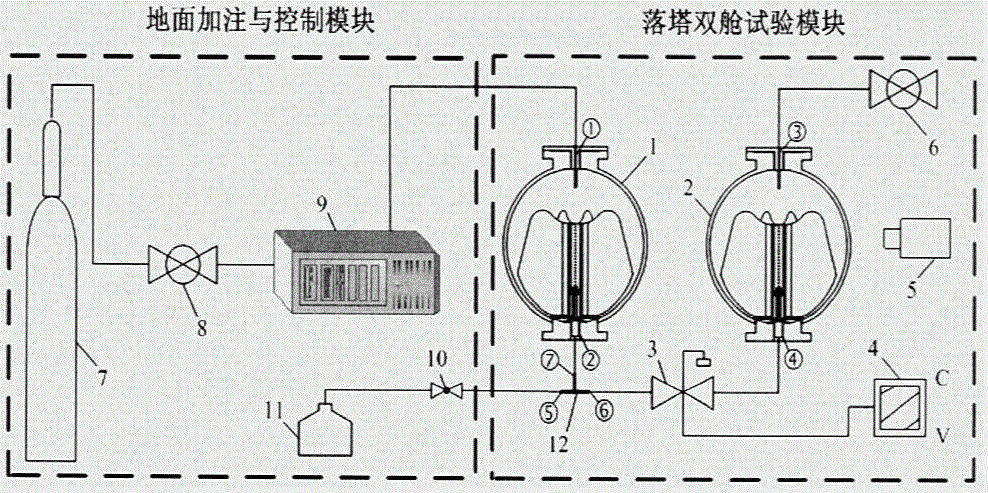

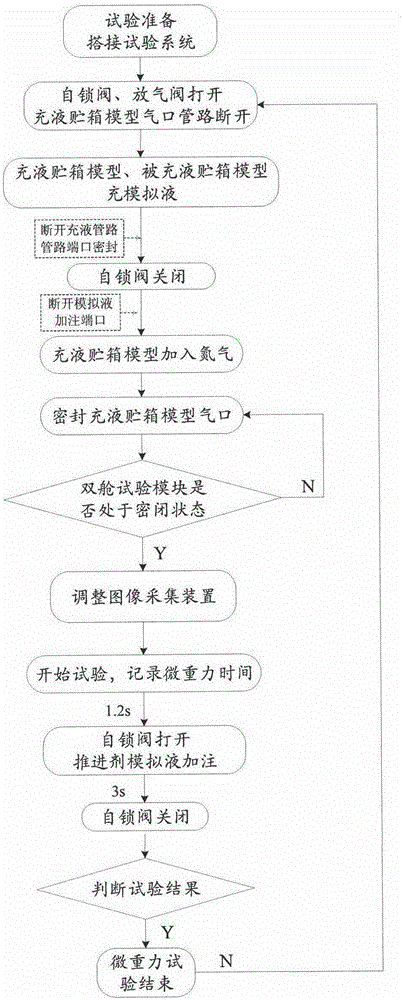

[0030] Such as figure 1 The structural principle of the microgravity test system for verifying the fluid transmission performance of the plate tank of the present invention is illustrated. The system of the present invention includes a liquid-filled storage tank model 1, a liquid-filled storage tank model 2, a self-locking valve 3, a self-locking valve controller 4, an image acquisition device 5, an air release valve 6, a nitrogen bottle 7, an air filling valve 8, Gas circuit console 9, filling valve 10, simulated liquid tank 11, and pipeline tee 12. The specific connection method of the system is as follows: use the high-pressure gas pipeline to connect the nitrogen cylinder 7, the gas filling valve 8, the gas circuit console 9 and the gas port ① of the liquid-filled storage tank model 1 in sequence, and the gas filling valve 8 is in the closed state; use PVC liquid pipes The road connects the simulated liquid tank 11, the liquid filling valve 10 and the liquid-filled storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com