Elastic-plastic body material for filling bridge gaps

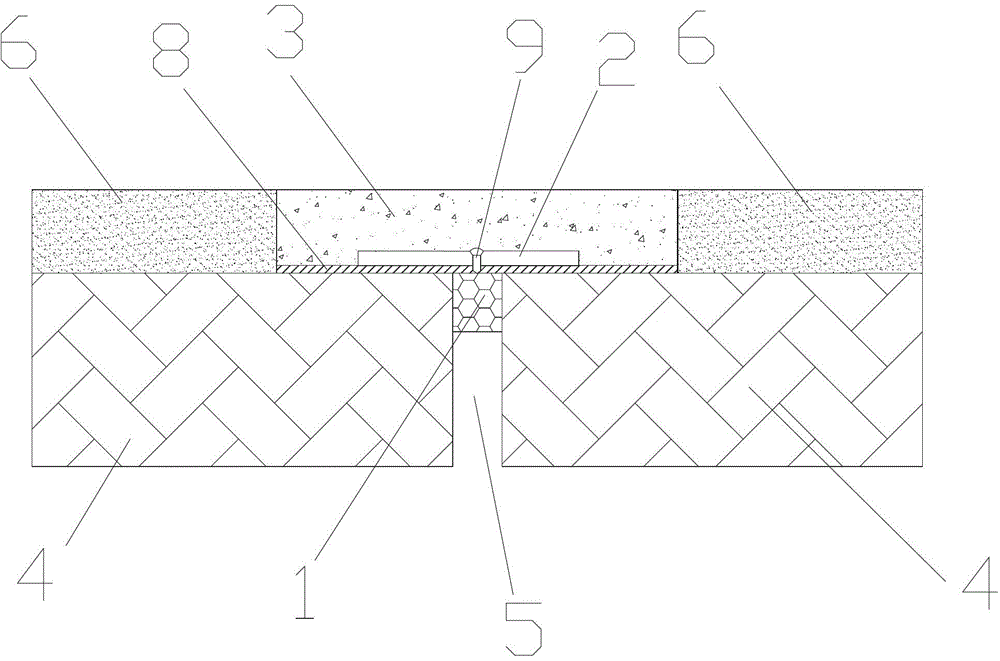

An elastic-plastic body and gap technology, applied in the field of elastic-plastic body materials, can solve the overall requirements of waterproof, anti-corrosion, shock absorption, load-bearing, elastic recovery ability, simple construction, etc. The overall requirements are not perfect, the comprehensive performance is not good, and the material structure Complexity and other issues, to achieve the effect of convenient and quick construction, low cost, and simple material structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment one: use 400 kilograms of crushed stones in the particle diameter range of 9.5mm-19mm and 100 kilograms of cementing material to combine, cementing material comprises petroleum asphalt, SBS, anti-rutting agent, talcum powder and petroleum resin, the composition of cementing material The weight percentages are as follows: 70 kg of petroleum asphalt, 3 kg of SBS, 5 kg of anti-rutting agent, 7 kg of talcum powder and 15 kg of petroleum resin. ;

Embodiment 2

[0025] Embodiment two: use 400 kilograms of crushed stones in the particle diameter range of 9.5mm-19mm and 100 kilograms of cementing material combination, cementing material comprises petroleum asphalt, SBS, anti-rutting agent, talcum powder and petroleum resin, the composition of cementing material The weight percentages are as follows: 80 kg of petroleum asphalt, 3 kg of SBS, 5 kg of anti-rutting agent, 5 kg of talcum powder and 7 kg of petroleum resin. ;

Embodiment 3

[0026] Embodiment three: use 400 kilograms of crushed stones in the particle diameter range of 9.5mm-19mm and 100 kilograms of cementing material combination, cementing material comprises petroleum asphalt, SBS, anti-rutting agent, talcum powder and petroleum resin, the composition of cementing material The weight percentages are as follows: 70 kg of petroleum asphalt, 6 kg of SBS, 5 kg of anti-rutting agent, 10 kg of talcum powder and 9 kg of petroleum resin. ;

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com