Method for preparing phenylacetate by using ionic liquid

A technology of phenyl acetate and ionic liquid, which is applied in the field of organic chemical synthesis, can solve the problems of complex post-treatment, difficult recycling of catalysts, and low yield, and achieve the effects of good thermal stability, easy operation, and simple reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

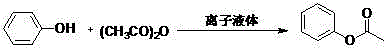

Image

Examples

Embodiment 1

[0016] 0.3 moles of phenol, 0.1 moles of acetic anhydride and 0.1 moles of [Pr 3 NH]HSO 4

[0017] Ionic liquid, stirred and reacted at 60°C for 8 hours. After the reaction was completed, water was added, and the product phenyl acetate was isolated, and the yield of the reaction was 93%; the water-soluble ionic liquid was used for the next experiment after dehydration.

Embodiment 2

[0019] Put 0.2 mole of phenol, 0.5 mole of acetic anhydride and 0.2 mole of [NMPH]HSO into the reaction vessel 4 Ionic liquid, stirred and reacted at 80°C for 10 hours. After the reaction was completed, water was added, and the product phenyl acetate was isolated, with a reaction yield of 89%; the water-soluble ionic liquid was used for the next experiment after dehydration.

Embodiment 3

[0021] 1.5 moles of phenol, 0.5 moles of acetic anhydride and 0.3 moles of [Me 2 NH]HSO 4

[0022] Ionic liquid, stirred and reacted at 90°C for 6 hours. After the reaction was completed, water was added, and the product phenyl acetate was isolated, and the yield of the reaction was 83%; the water-soluble ionic liquid was used for the next experiment after dehydration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com