Quick-response direct force generating device

A generation device and fast-response technology, which is applied in the field of aerospace vehicle control, can solve the problems of adjustable and controllable operating frequency and jet velocity of difficult actuators, increase the complexity of cavity processing and packaging, and achieve simple structure, Quick response and extended application range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

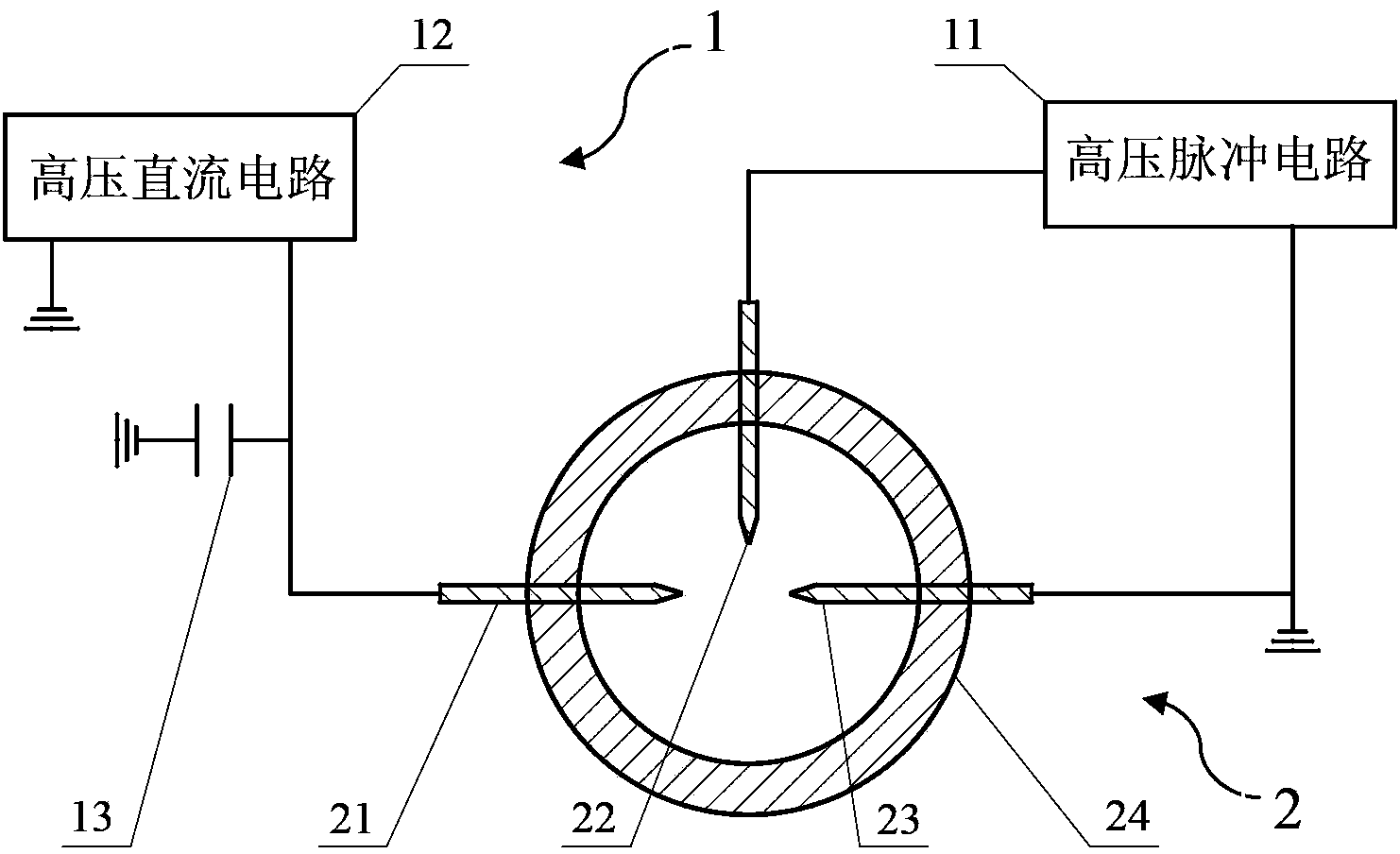

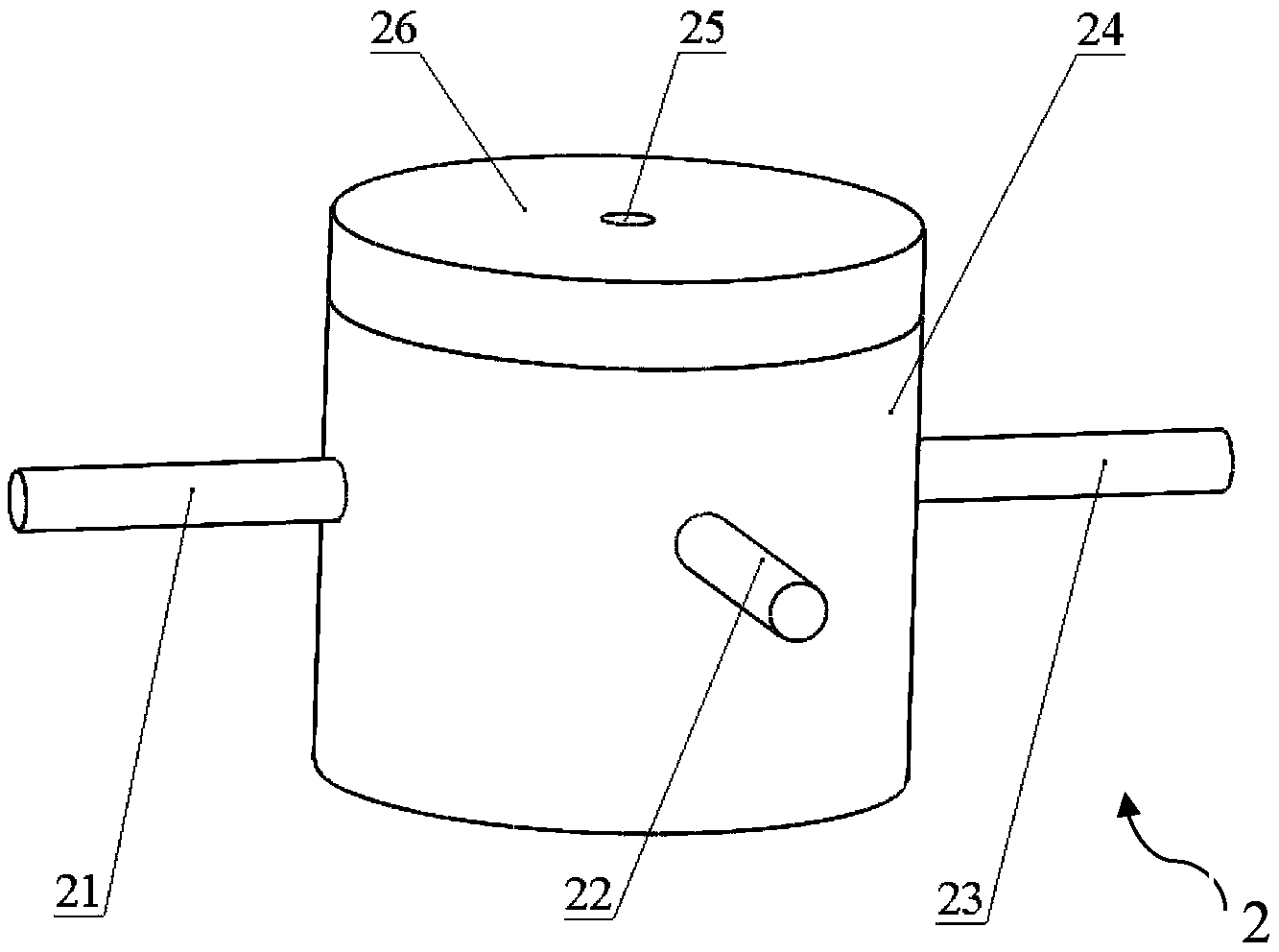

[0025] See attached Figure 1~2 , an implementation example of a fast-response direct force generating device of the present invention, which is composed of a power supply system 1 and a spark discharge plasma synthetic jet actuator 2 . Wherein the spark discharge plasma synthetic jet actuator 2 such as figure 2 As shown, a cylindrical exciter body 24 is included, the section diameter of the exciter body 24 is Φ16mm, and the height is 20mm. The exciter body 24 and its cover plate 26 are made of commercially available glass ceramics or boron nitride ceramics with good insulation performance and machinability to reduce the processing difficulty of the exciter. The diameter of the cover plate 26 is the same as that of the exciter body 24. The diameter of the tube is matched, and the thickness is 3mm. The jet outlet hole 25 opened on the cover plate 26 is circular, and its diameter is Φ2mm. The jet outlet hole 25 can also choose different side inclination angles or pitch angles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com