Method for simultaneously measuring laser absorptivity and thermal conductivity of single micro-nano wire rod

A technology of micro-nano and absorptivity, which is applied in the direction of measuring heat, measuring devices, and thermal development of materials, etc. It can solve the problems of not being able to obtain temperature distribution, increasing the uncertainty of temperature measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0045] Utilize the method involved in the present invention to measure the laser absorptivity and thermal conductivity of single carbon nanotube, specific embodiment is as follows:

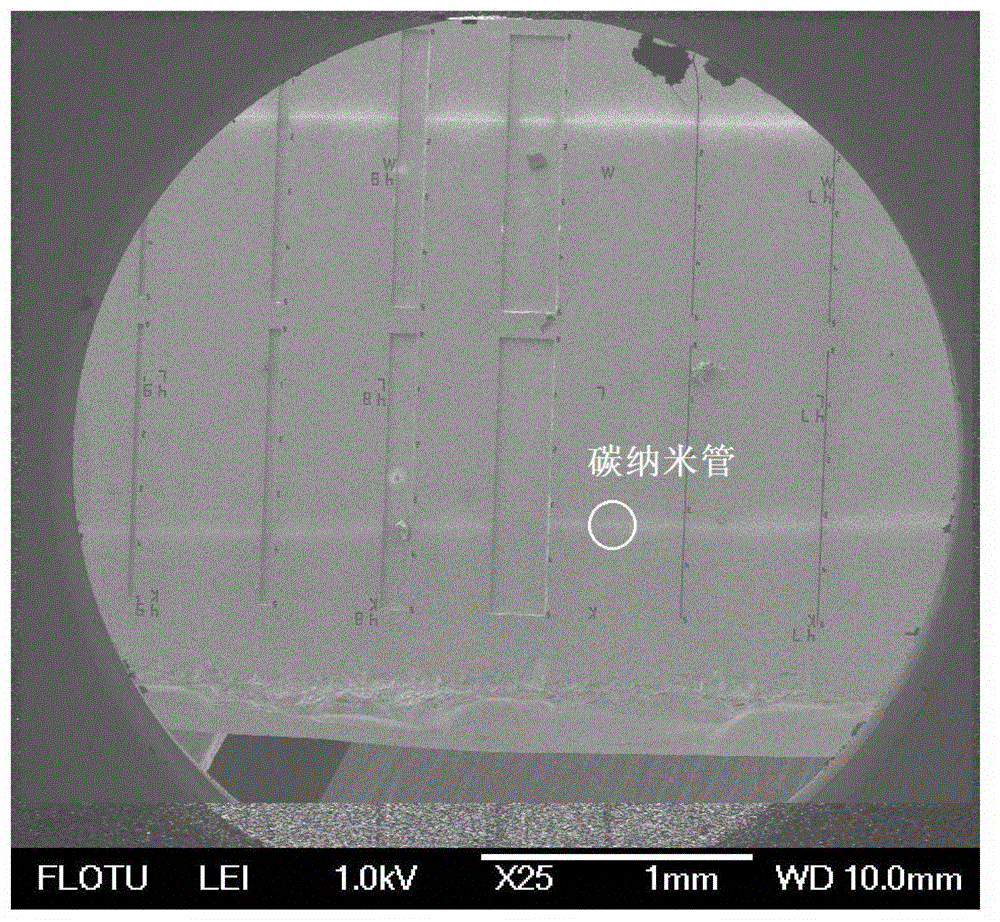

[0046] (1) A plurality of carbon nanotubes were prepared by chemical vapor deposition on a silicon dioxide / silicon substrate, and the middle part of the carbon nanotube sample was suspended above the groove of the substrate for Raman measurement. Electron micrographs of carbon nanotube samples as figure 1 As shown, the circle marked is the single carbon nanotube measured in the embodiment, and the rest of the carbon nanotubes that hinder the measurement can be burnt with a strong laser focus.

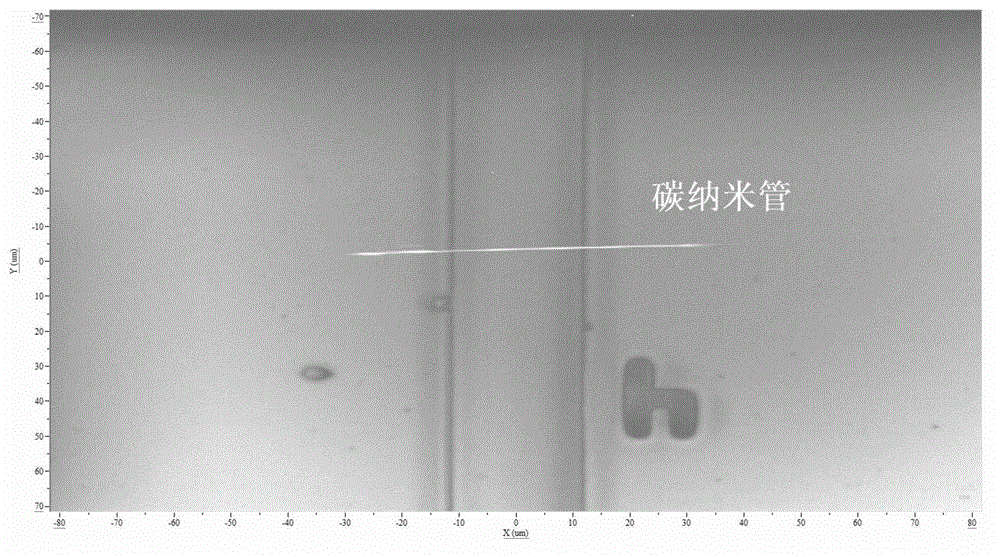

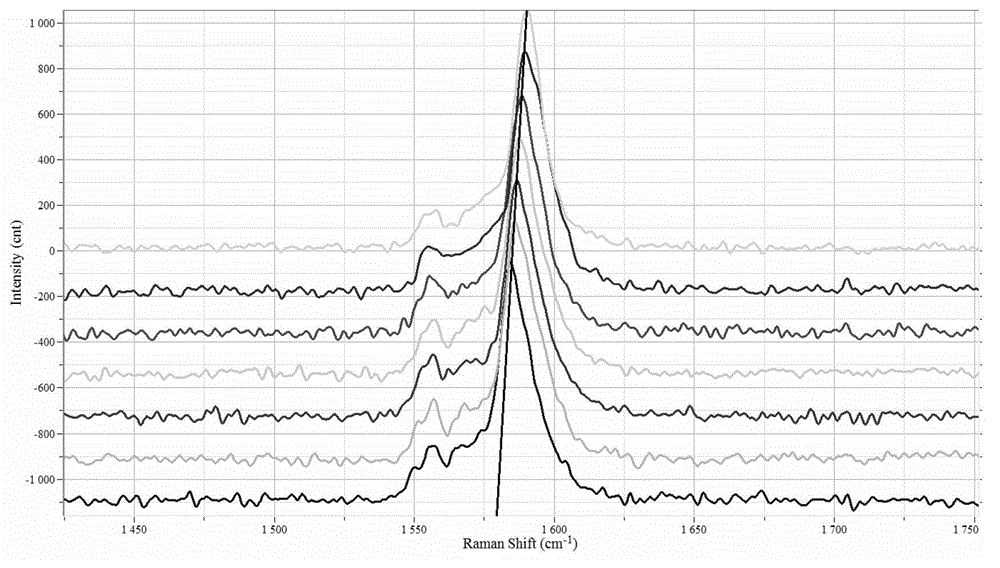

[0047] (2) Because the diameter of carbon nanotubes is on the order of several nanometers, optical microscopes cannot directly observe carbon nanotube samples. In our experiment, the T64000 three-stage grating Raman spectrometer of HORIBA Company was used to scan the characteristic Raman signal of carbon n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com