Lubricating oil composition for bearings

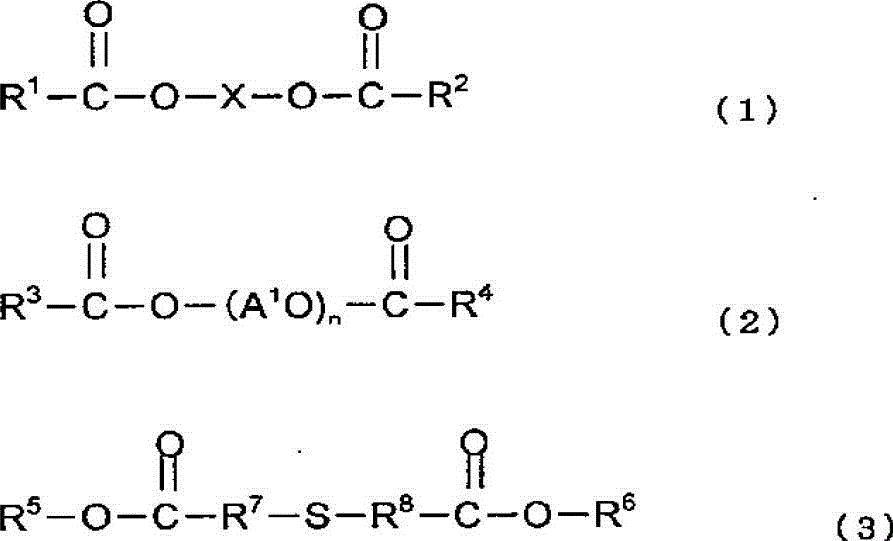

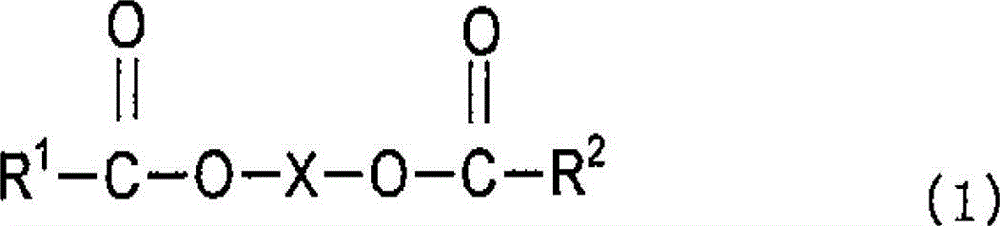

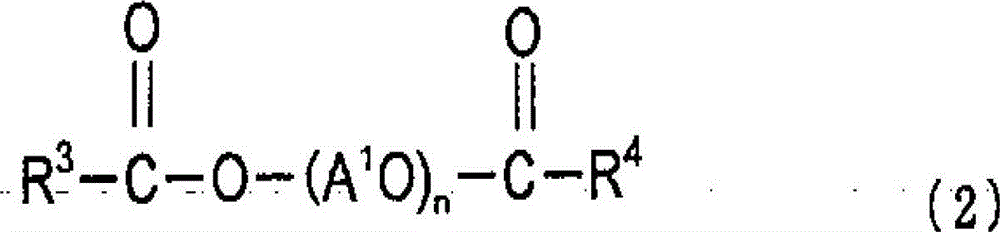

A technology of lubricating oil and composition for bearings, applied in the direction of lubricating composition, bearing components, shafts and bearings, etc., can solve problems such as easy volatilization, high friction loss of equipment, increased evaporation loss of lubricating oil, etc., and achieve viscosity index High, low evaporation loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0135] Manufacture of diester (A1-1)

[0136] 255.0 parts of neopentyl glycol, 701.3 parts of heptanoic acid, and 48 parts of xylene were charged into a reaction vessel equipped with a stirring device, a thermometer, a nitrogen inlet tube, and a water fractionation receiver with a condenser tube, under a nitrogen environment , heated up to 200°C. The esterification reaction was carried out for about 10 hours while removing the distilled generated water with a water fractionation receiver to target the theoretical amount of generated water (88 g). After completion of the reaction, excess acid and xylene were removed by distillation to obtain a crude product of esterification. Next, the obtained esterified crude product was transferred to an eggplant-shaped flask equipped with a Vigreux fractionator, and distillation was performed at 220° C. under reduced pressure. 15% by volume of the initial fraction and the final fraction were removed by vacuum distillation, and the middle ...

manufacture example 2

[0138] Manufacture of diesters (A1-2)

[0139] Except that the feeding was changed to 277.5 parts of 3-methyl-1,5-pentanediol, 672.6 parts of heptanoic acid, and 48 parts of xylene, it was carried out in the same manner as in Production Example 1 to obtain the diester (A1 -2): 3-methyl-1,5-pentanediol di-n-heptanoate (molecular weight 342). (A1-2) had a total acid value of 0.01 mgKOH / g.

manufacture example 3

[0141] Manufacture of diesters (A1-3)

[0142] Except that the feeding was changed to 255.1 parts of 3-methyl-1,5-pentanediol, 684.9 parts of octanoic acid, and 47 parts of toluene, it was carried out in the same manner as in Production Example 1 to obtain the diester (A1-3 ): 3-methyl-1,5-pentanediol di-n-octanoate (molecular weight 371). (A1-3) had a total acid value of 0.01 mgKOH / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com