Method and apparatus for rapidly stabilizing catalyst activity by heavy fuel oil

A technology of heavy fuel oil and catalyst, applied in the direction of catalyst protection, chemical instruments and methods, physical/chemical process catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

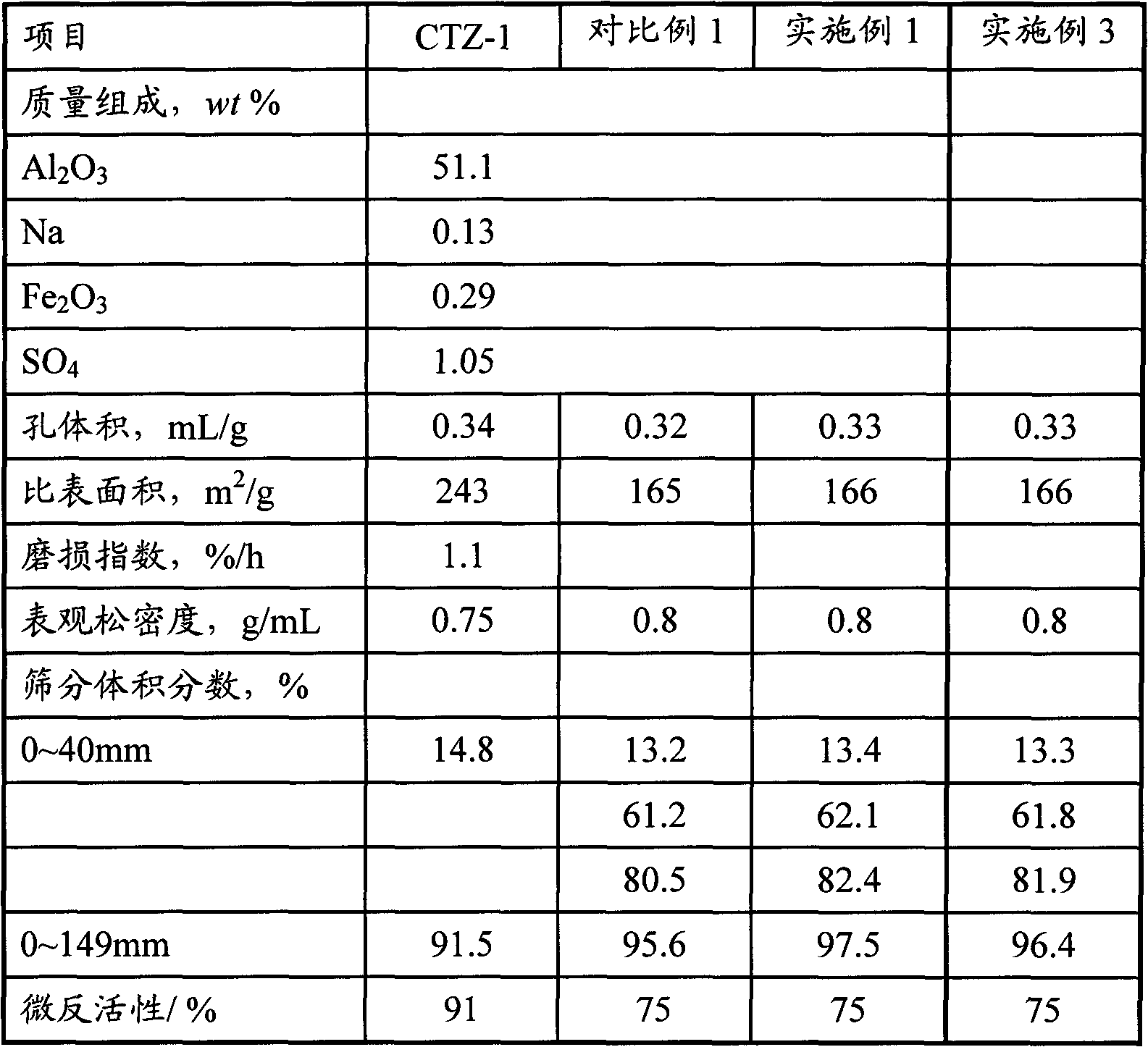

[0058] Example 1 illustrates the catalyst aging effect of the method provided by the present invention.

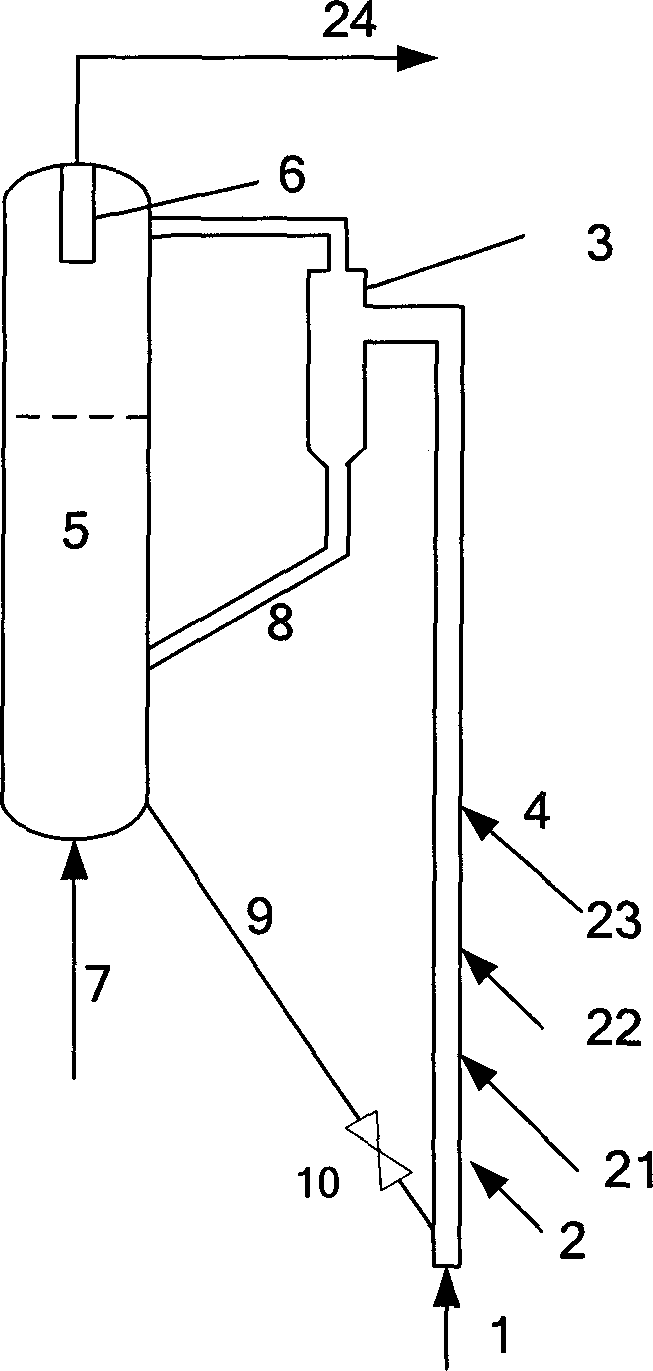

[0059] The process flow of the catalyst aging device structure is attached figure 1 As shown, the catalyst aging device includes a fluidized bed reactor 5 and a dilute-phase combustion pipe 4. The catalyst in the fluidized bed reactor enters the bottom of the dilute-phase combustion pipe 4 through a pipeline 9 and a control valve 10, and is connected with the air from the pipeline 1. After mixing, change the flow direction of the catalyst, go upward along the dilute-phase combustion tube, and then mix with a part of oil slurry from pipeline 2 for combustion reaction. Then inject air through the pipeline 21 to make it burn; then spray the remaining oil slurry into the riser reactor through the pipeline 22 to make it contact with the catalyst, make it evenly dispersed on the catalyst, and then inject air through the pipeline 23 to make it burn; The gas and catalyst after t...

Embodiment 2

[0062] Example 2 illustrates the effect of the aging catalyst provided by the method used in the catalytic cracking reaction.

[0063] The medium-sized device and raw oil in Comparative Example 2 were adopted, and the operating steps and reaction conditions were the same as those in Comparative Example 2, except that the catalyst was the catalyst with reduced activity obtained by aging in Example 1. The properties of the raw oil are shown in Table 4, and the reaction conditions and results are shown in Table 5.

Embodiment 3

[0065] Example 3 illustrates the catalyst aging effect of the method provided by the present invention.

[0066] The aging device and aging method adopted are the same as in embodiment 1, except that the fuel injected in the dilute phase combustion tube is diesel oil.

[0067] The properties of the fresh catalyst CTZ-1 are shown in Table 1, the fuel is diesel, its properties are shown in Table 2, the operating conditions are shown in Table 3, and the properties of the aged catalyst are shown in Table 1.

[0068] Example 2

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com