Rapid automotive paint make-up machine

A paint spraying machine, patent-applied technology, applied in the direction of pretreatment surface, spraying device, coating, etc., can solve the problems of slow drying of paint solvent, large paint mist scattering surface, low air cleanliness, etc., and reach the harm of human body and environment Low, cost-saving effect of paint

Inactive Publication Date: 2013-03-06

董丹

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

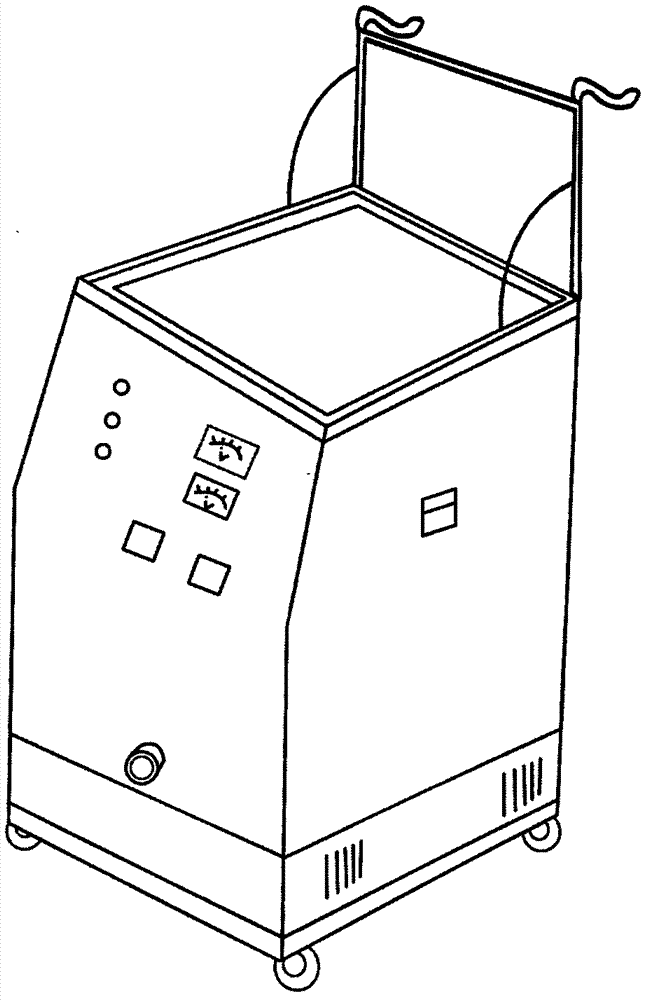

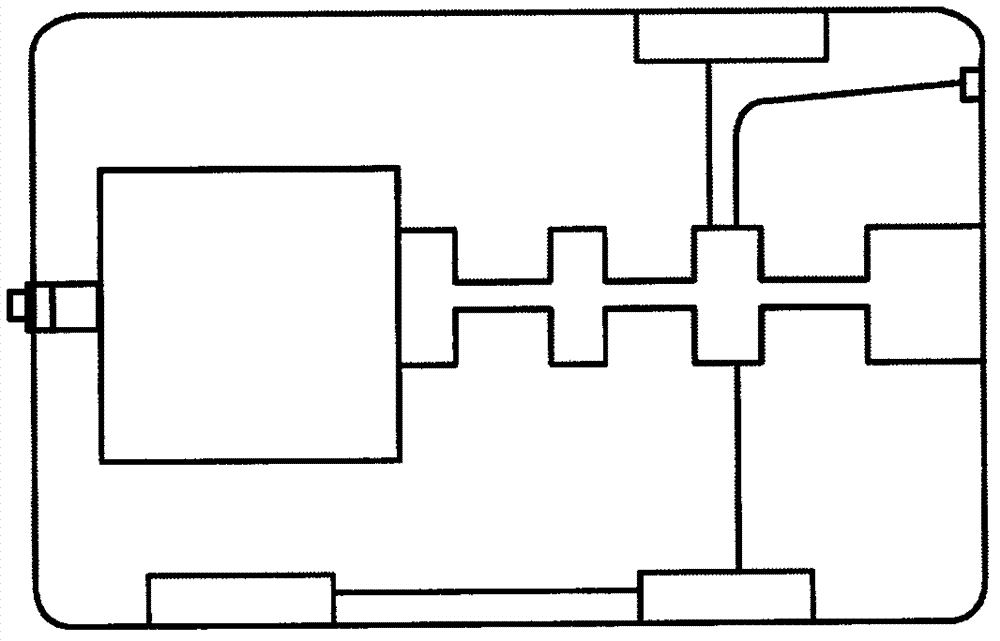

[0005] The turbocharged balanced pressure air supply system inside the paint touch-up machine, the automobile engine-type air filtration technology, the automatic heating and drying technology and the super-environmental friendly HVLP spot-shooting spray gun make four important elements that restrict the painting effect and speed: poor air supply stability, air Problems such as low cleanliness, slow drying of paint solvents, and large paint mist scattering surfaces have been revolutionaryly solved! At the same time, the paint touch-up machine only needs a two-phase power supply, plug and play, eliminating the cumbersome and troublesome work of air compressor-dryer-gas storage tank-single group / double group oil-water separator-pipeline-baking room. large investment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0019] Manufacture finished machines and put them into large-scale production to provide equipment, new technology support, energy saving and environmental protection for the car maintenance and beauty market.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

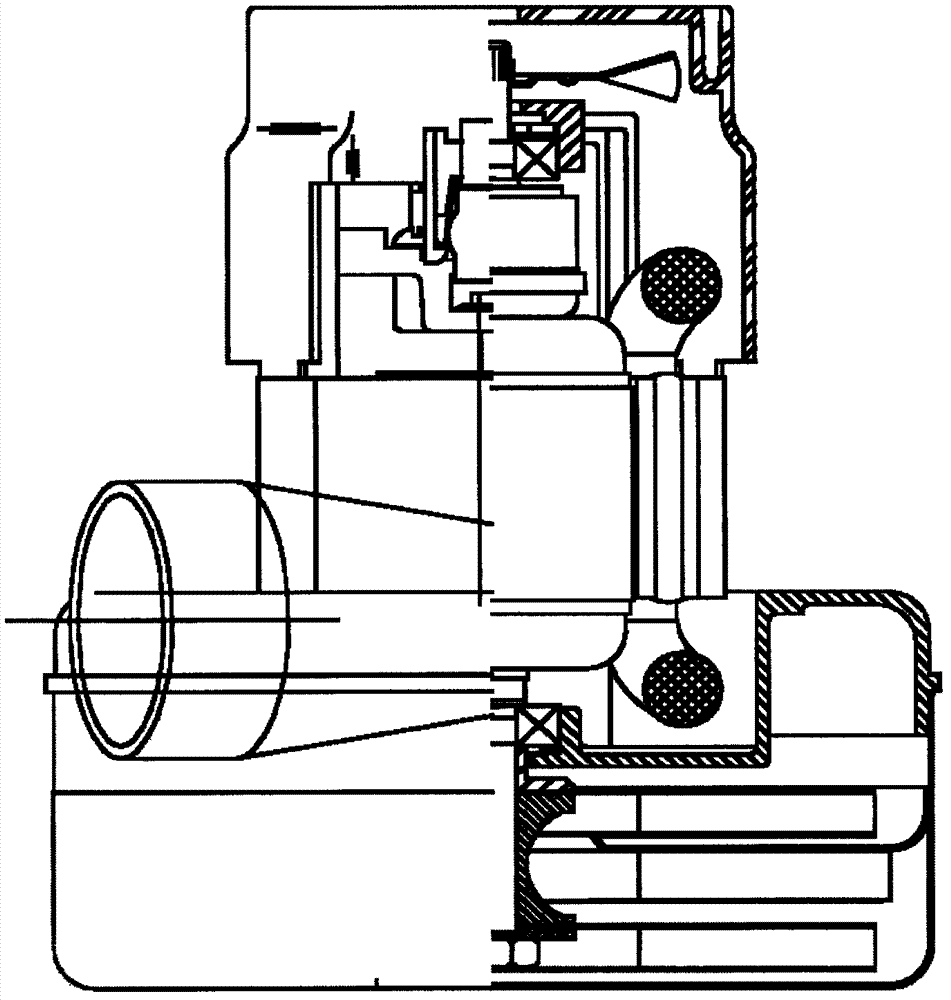

Four important problems, restricting paint spraying effect and speed, of poor air supply stability, low air cleanliness, slow paint solvent dryness, large paint mist scattering surface and the like are solved revolutionarily by the aid of a paint make-up machine internal turbocharging air supply system, the automotive engine type air filtering technology, the automatic heating and drying technology and a super environment-friendly HVLP (high-volume low-pressure) spot spray gun. A constant-temperature constant-pressure turbine air supply machine serves as a main machine core of a rapid automotive paint make-up machine and serves as an air pressure source for providing all air.

Description

1. Technical field [0001] This technology is suitable for automobile maintenance and automobile beauty industry. Breaking the history of spraying paint in traditional paint booths, simple operation, better effect, energy saving and environmental protection. 2. Background technology [0002] At present, the rapid paint repair technology in China is still in its infancy, and there are mainly two forms of technical characteristics: [0003] The first form: work hard on varnish (varnish). While spot drying is fast (i.e. varnish dries faster), the results are good. However, after one or two months, there will often be problems with the bottom layer or the paint surface not being completely dry, and blistering and cracking on the repaired surface. The after-sales problem of this technology is quite serious, and the dissatisfaction of car owners is serious. It mainly appears in the promoters who use the concept of "UV ultraviolet rays" and "light compensation". In fact, UV ultra...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B05B13/00B05B12/00B05D3/02

Inventor 董丹

Owner 董丹

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com